UAVs

(Image courtesy of Unmanned Aerospace)

Aerial pioneers

Rory Jackson investigates a plethora of UAVs breaking the mould in terms of configurations and distinguishing technologies

While much experimentation and novel approaches were applied to crewed aerospace throughout the 20th century, including sleeve-valve engines, tilt-wing aircraft configurations and supersonic jets, most of professional aviation across industry remained heavily uniform, owing to both regulation and manufacturing efficiency reliant upon standardised, mass-produced, structural and powertrain components.

Surveys, search-and-rescue operations and anything else requiring judicious eyes in the sky were carried out by helicopter crews; passengers across and between continents were flown in lengthy, tubular, fixed-wing CTOL aeroplanes; and military duties were similarly divided-up between helicopters, CTOL planes and, on rare occasion, VTOL-transitioning or STOL planes.

UAVs, however, have upended the status quo by using unusual and unconventional aircraft configurations quite unlike those of conventional, standardised aviation. The absence of a pilot, and the freedom to look beyond the regulated and the standardised, has unlocked great creativity for engineers in the pursuit of limitless performance and efficiency.

It has also enabled duties typically carried out by conventional aircraft forms to be taken on by unconventional systems, to the benefit of customers and society alike.

Logistics

Over the years, we have seen some incorporation of autogyro technology into UAV architectures for the simplicity and energy efficiency that autogyros (sometimes called ‘gyrocopters’) can bring to aircraft operations and maintenance.

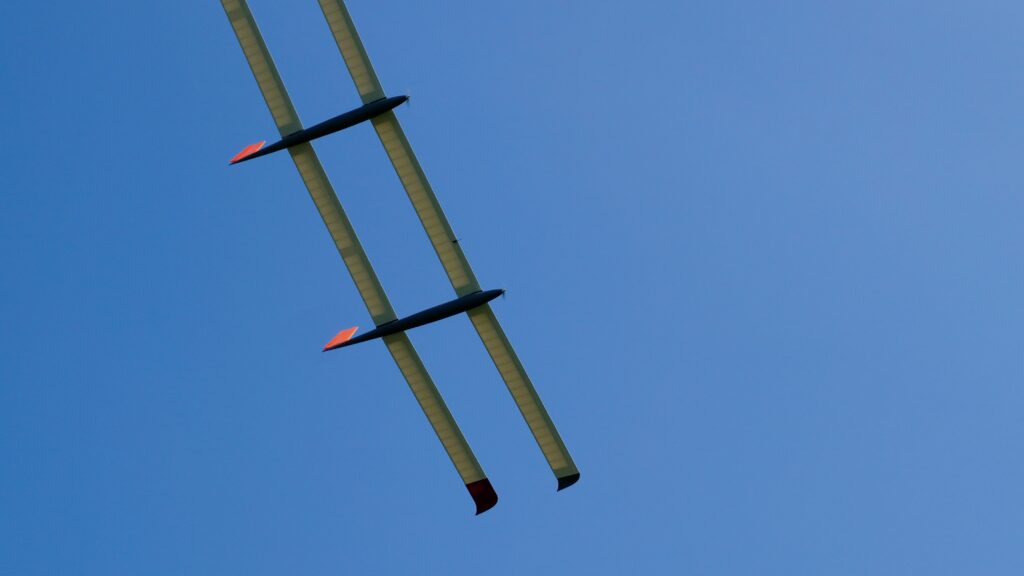

The latest we know of comes from Unmanned Aerospace, whose GH4 – short for ‘Gyrocopter-Helicopter, 4th generation’ – features an overhead rotor that spins freely, as on an autogyro, but whose blades can also be pitched from the conventional zero-pitch angle to a ‘VTOL-pitch’ angle by way of a unique mechanism invented and patented (across 11 patents granted and 6 pending) by the company.

“As you know, gyrocopters have no VTOL capability because the principle by which their overhead rotors generate lift requires that their blades maintain almost zero pitch. But we can transition between pitch regimes without using anything helicopters use,” Gad Shaanan, CEO of Unmanned Aerospace tells us.

“Helicopters have been advanced greatly over the past several decades, but their mechanisms remain very complex and very maintenance-intensive. We have maybe 10% of their complexity and, on top of that, we’re hydrogen-powered, combining hydrogen fuel cells with booster batteries, giving us up to 30 minutes of green hovering power.”

Total flight time potentially exceeds four hours, depending on hover time versus forward flight time, as well as payload, battery and fuel tank complements. An integrated rack system enables 15 lb (6.8 kg) of payload capacity, which can also be dropped as needed for quick delivery operations (Shaanan suggesting shore-to-ship work as one of several suitable niches for the GH4).

The overhead rotor is powered to enable the rpm necessary for take-off, hovering and landing. The GH4 also integrates two electric tractor propellers on short wings for forward flight, during which the overhead rotor is depowered so that the craft can function as an autogyro (and hence the rotor moves passively at speeds of 350-500 rpm), including a conventional integrated teeter mechanism via which the advancing and retreating blades can be adjusted for optimal flight efficiency.

At the time of writing, the GH4 has racked up around 50 hours of test flights (including a fail-fast approach to eliminate all significant points of failure, and to ensure fast and far-reaching improvements), with more planned. Tests thus far having included flights using aluminium frames to validate the transition mechanisms and various custom subsystems.

“Everything is custom, or at least a heavily reconfigured off-the-shelf item, except for the fuel cell,” Shaanan says.

“The autopilot comes from Embention, and we’ve been programming and programming it because there’s no off-the-shelf autopilot that fits the gyro-helicopter hybrid flight mechanisms we have; we’ve had to test the transitioning between VTOL mode and gyro mode a great deal to build software control from the ground up.”

The fuel cell powertrain meanwhile has been supplied by Intelligent Energy, with three of that company’s 1.2 kW PEM fuel cells connected to enable up to 3.6 kW of power collectively, for recharging the battery and thereafter powering onboard subsystems. Unmanned Aerospace has additionally iterated the powertrain design heavily to ensure effective thermal management, extraction of hot air being more challenging inside the GH4’s sealed fairings than on the industrial multi-rotors typically integrating the fuel cells.

“The GH4 ends up looking a bit like a shark because we now have gills on the sides behind the nose to let the air extract. Simultaneously, we have ducting inside to help get the hot air out, with an intake scoop on the bottom. Intelligent Energy have been a great help throughout the whole design and integration process,” Shaanan adds.

“In addition to Intelligent Energy and Embention, we also work with multiple other European suppliers, including Plettenberg for the electric motors and Mejzlik for the propellers. For every part, we’ve really looked to start with the best of the best COTS products, and then afterwards look into what can be tuned back for closer efficiency through customisation.”

The company aims to begin pilot production of commercial units of the GH4 by Q1 2026; it is also planning a GH5 and GH6, which will carry around 110 lb (49 kg) and 350 lb (158 kg), respectively.

Earth observation

Although the cost of launching cubesats and other orbital observation and mapping tools has dropped significantly in recent years, from millions of dollars to tens of thousands in some cases, so too have the costs of producing solar-powered HALE (high-altitude, long endurance) UAVs, capable of soaring through the stratosphere with theoretically limitless flight time. For many, the latter represents greater safety and reliability, not to mention far better affordability.

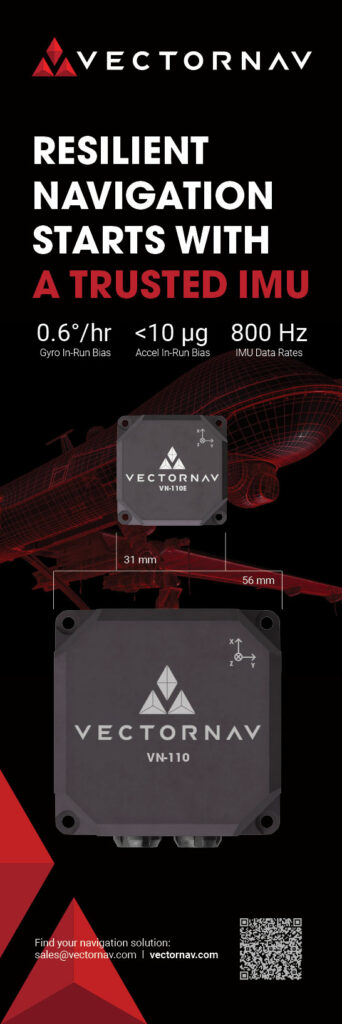

(Image courtesy of Windhover Labs)

Offering a more price-economic alternative to cubesats (as well as weather balloons and other methods of stratospheric and orbital surveying) motivated US-based company Windhover Labs to begin work on its Eterna HALE UAV around three years ago, the aircraft having sported a dual fuselage, tandem wing architecture since its inception.

“That configuration helps Eterna deal with some of the aeroelastic stresses that HALE UAVs can induce when built with an overly large wingspan,” says Cyrus Shy, engineer at Windhover Labs.

“We can integrate a range of payloads inside either fuselage, with up to 5 lb across them collectively, and we hope to increase that limit over time, pending better battery technologies becoming available to us as well as a cost-effective route towards quality solar cells.”

Given the cost of flexible solar cell technology remaining high, Windhover continues to research ideal choices for maximising the weight-per-kilogram of energy generated onboard, while maintaining reasonable bill of parts costs for the eventual production version of Eterna. However, the growing availability of COTS solar modules is helping to keep their prototype testing and iteration costs low.

“We successfully completed our first flight in early May, which validated the flight control and aero design, and our next step is indeed going to be solar panel integration,” Shy says.

“A lot of the low-price modules we’re able to test with are quite flexible but still fragile, and some of the quotes we’ve had from solar material companies are really high but their quality is still tempting. One company we’ve met with can actually infuse the photovoltaic panels into carbon fibre and fibreglass lay-ups for a very well-integrated part.”

As mentioned, advancements in batteries are also key to Windhover’s development plans, and any such innovations that enable low-price energy storage as well as weight reduction are especially valued; because, in addition to making a price-competitive HALE UAV, the company plans to optimise energy usage by ascending during daylight and descending (for lowered power consumption) at night, similar to other HALE companies like Aalto (see Issue 53).

“One other method we’re planning on utilising for energy efficiency is utilising the jet streams of Earth’s atmosphere to propel Eterna around the world,” Shy continues.

“It’ll take quite a bit more testing before we can achieve that; the UAV is designed for 8 g of force at the moment, which makes it pretty robust, but we don’t want to just assume it’ll be able to handle the fast-flowing air currents.

“It’s pivotal for us to gather as much data as possible from those conditions at those altitudes, so we can understand what our in-house flight computer’s readings will look like when the UAV is flying in the jet streams, what the sensor data will look like and whether we can maintain our data links. That’ll definitely be a scary day when we direct Eterna into a jet stream for the first time, but we’re very much looking forward to it!”

The Eterna’s flight computer product, Ravenity, sprung from the company’s background in aerospace control software and avionics as a fault-tolerant and certifiable system for autonomy and vehicle management. Meanwhile, the company is also working on Dragonfly, a tube-launched long-range survey UAV with military and civilian variations, both of which fly using Ravenity.

Wildlife survey

In addition to solar cells being a mainstay of stratospheric UAVs, low-altitude drones can also find their flight times and other capabilities enhanced through use of photovoltaics.

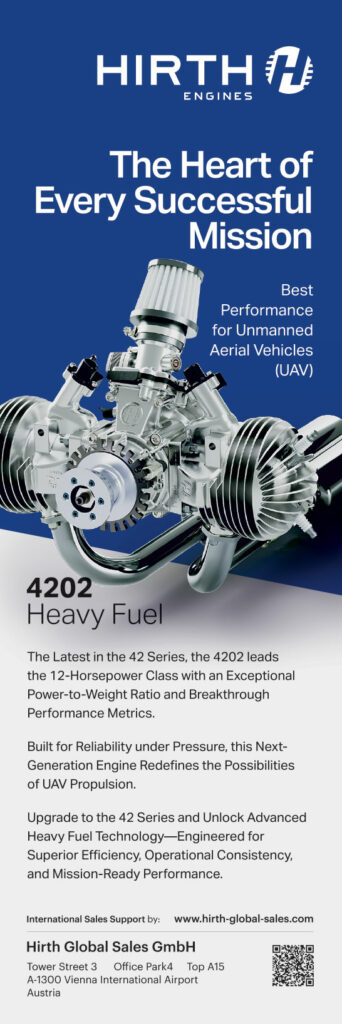

The SW-117 UAV from Canada-based Superwake, which is a fixed-wing, catapult-launched, 5.3 m wingspan aircraft, is capable of flight distances exceeding 300 km through its solar wings and 2 kWh of onboard batteries. However, it originated from a research project aimed at breaking the world record for uninterrupted UAV flight (at the time of writing: 67 days, as set by the Aalto Zephyr earlier in 2025, extending its previous record by three days).

“Over the course of our r&d, we opted to instead spin-off this more commercially-oriented UAV, which is ruggedised and purpose-built for a range of payloads and missions,” says Michael Melville, COO of Superwake.

“We’ve designed the SW-117 with targets such as maximising the wing area, to fit as much solar cell material on there as possible – 80-90% of the wing top surface area is solar panel – and chasing weight-shedding in everything we can to grab every last second of endurance.”

(Image courtesy of ZenaTech)

Among the applications for which the UAV is suited, the company notes that it has successfully carried out wildlife surveys in Canada, including deer and elk surveys in the Yukon territory and a broader ungulate survey covering Riding Mountain National Park (requiring flight over more than 3000 km2) in Manitoba. These missions utilised a NightHawk2-UZ EO/IR gimbal from NextVision, and validated the SW-117’s ability to work continuously in -40 C temperatures.

To maximise affordability and hence commercial viability in Superwake’s business model, most of the design work has been performed in-house, and conventional monocrystalline silicon is used in the UAV’s solar panels.

Livestock management

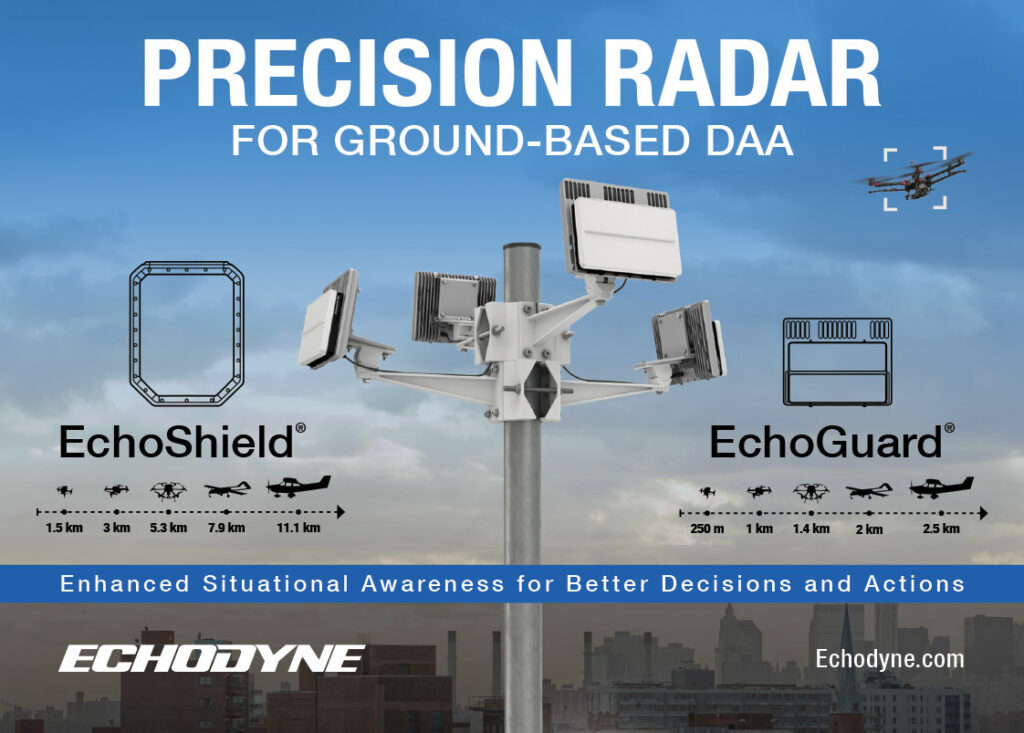

Although there are growing numbers of UAVs known to perform wildlife surveys across vast landscapes and national parks, livestock are often given comparable space to roam and graze, in which they can become near-impossible for farmers to track and care for effectively.

Loss of cattle can cost farmers dearly, and searching by horseback or small off-road vehicle can take hours and put the farmer at risk, particularly given the uneven terrain or inclement weather that can be characteristic of acres of grazing land. UAVs, however, can survey large swathes of open area quickly, regardless of terrain; and as for weather, the ZenaDrone 1000 from ZenaTech is an example of an aircraft built with a weather-resistant outer shell and a high-power distributed-lift architecture that enables it to continue surveying in high gusting and rainy conditions.

The large octocopter is designed for a 40 kg payload capacity, in which it can incorporate multiple sensors including EO/IR, NIR and Lidar, as well as video encoders and radios for transmitting real-time video of its sensor data back to farmers. That includes mission software for geo-tagging individual cows, and temperature-sensitive AI analytics of individual herd members’ health and the condition of grazing grounds – all designed to better track the distribution of cattle and their well-being.

Through ZenaTech’s mission management software, farmers can also specify ground that they consider unsafe for cattle, enabling UAVs to activate an alert when cows trespass, improving the speed of interventions.

The ZenaDrone 1000 has been in development for a few years to optimise its high-level architecture, and the company tells us that it plans to test the UAV’s forward flight mode shortly. The octocopter’s in-house tiltrotor-like design enables the ZenaDrone 1000 to transition between VTOL and forward flight by way of servos twisting its motor arms into a forward-facing position.

Having designed the UAV’s whole body as a lift-generating surface, it is designed to maintain up to an hour of flight time on just batteries, although the aircraft has the internal volume for hybridised powertrains and fuels for longer flight times. The company presently engineers it as a battery-electric air vehicle as standard in pursuit of sustainability, but they have announced that they are working on a gas-powered version.

As of the time of writing, most onboard systems have been developed in-house, and ZenaTech’s vertically integrated operating model includes manufacturing PCBs, sensors and cameras in Taiwan through a subsidiary company established for NDAA-compliant components for US defence. The company is currently establishing relationships with a number of external suppliers in the short term, to leverage high-quality COTS and custom subsystems towards maximising the UAV’s capabilities and cost-effectiveness.

City surveys

VTOL-transitioning systems are becoming increasingly prevalent for BVLOS operations, even in critical surveys for major industrial and urban infrastructure, for the mounting improvements in their gust tolerance and general certifiability (as well as their already competitive cost and efficiency versus those of helicopters, given the lack of launch or recovery infrastructure needed to operate them).

By taking on missions extending over thousands of miles and tens of thousands of acres in the months ahead, the Sentaero 6 UAV (launched in February 2025 and shipping as of July) from Censys Technologies is achieving areal coverage that is an order of magnitude greater than that of its predecessor, the Sentaero 5. Such missions will include Lidar mapping the entire Florida peninsula surrounding Censys’ headquarters, as well as a number of approved flights over populated areas.

As Kyle Miller, director at Censys Tech explains, “The Sentaero 5 and everything before it was essentially a single sensor for a single hour. However, the Sentaero aircraft have been developed continuously for eight years now, and the Sentaero 6 features similar autopilot and C2 tech as the 5, but the overall aircraft is updated to provide multi-sensor and multi-hour operations.

“To that end, the Sentaero has been enlarged to around double the size of the Sentaero 5, to carry a payload bay that can integrate both RGB cameras and Lidars, with a fully composite structure, a bigger battery, bigger everything! We serve a lot of transportation and energy utility customers, who’d contributed to the Sentaero 5 having 20% of all active BVLOS waivers in the US. So, we really wanted to build on that with the Sentaero 6 with more flight time, multi-sensor data collection and higher certifiability.”

One especially significant change has been the integration of an ASTM-certifiable parachute, which will enable Censys and its customers to obtain waivers for flying over areas with dense population and moving vehicles consistent with cities, and its plans include surveys over major urban centres such as Manhattan and Miami.

(Image courtesy of Censys Technologies)

“But before we start going over major metro areas, there’s a lot of real estate outside of the urban hubs themselves where we can fly now, for use-cases like road inspections, public safety and utility monitoring,” Miller adds.

The UAV achieves up to two-to-four hours of flight endurance on its 27-36 Ah modular battery packs, with the energy storage and flight time changing depending on mission and payload requirements. VTOL is enabled through four twin boom-mounted VTOL motors and a pusher rear propeller enabling forward flight.

While the Sentaero 5 was a tiltrotor, the company came to find over time that the tilt-servos’ added points of potential mechanical failure were not worth the aerodynamic efficiency advantages of tiltrotors over the relative simplicity of fixed VTOL motors. It additionally reports that the single, large pusher prop is able to provide more efficient propulsion than four smaller props tilted horizontally.

“And as well as that improving our endurance and our lifespan between maintenance, maximising our comms range out to 100 miles was really thanks to Elsight,” Miller adds.

“We’ve been an integrator of the Elsight Halo platform for many years, which has unlocked all the ranges we claim. We always maintain C2, even in areas of sparse connectivity; we still have a radio on the UAV for when users are truly in an LTE wasteland, and Silvus is our choice for direct radio links.

“It’s still a modular aircraft intended for open configurability, and having the same airframe every time helps us manufacture at scale, but we also tailor the aircraft around a common set of components. If users need the Halo LTE plus Silvus, we can do it; if they need detect-and-avoid in the front, we can do it; if they need more endurance, we can swap something out for an extra battery. We’ve done all sorts of permutations over the years, and it’s now very open with the Sentaero 6.”

Resident applications

As with any resident uncrewed surveying product, drone-in-a-box solutions represent a long-lasting and cost-effective means of repeatably surveying fixed infrastructure. Installing enclosed stations near remote dams, rail facilities and the like, for recharging UAVs while protecting them from the elements, saves human personnel from having to drive out and launch inspection missions themselves. It additionally saves companies from conducting very long-distance UAV flights just to inspect a single point at the end of a 2-3 hour journey.

However, such small, battery-powered, multi-rotor-type solutions cannot provide enough survey range for owners of lengthier or wider-spread fixed assets, such as power lines or pipelines. Permanently installing a UAV station for launch, recovery and charging every 10 km would prohibitively drive up the cost of investment and maintenance.

(Image courtesy of Starling Systems)

Instead, Starling in the US has combined its Starling Hub drone-in-a-box station with its Pathfinder UAV, which is a VTOL-transitioning fixed-wing aircraft, possessing folding wings and a folding tail that enable it to be stowed compactly inside the aforementioned docking station, making for a more capable and convenient resident UAS than prospective customers might typically be used to.

“Being a fixed-wing drone-in-a-box allows it to fly with three times the range and endurance that a conventional multi-copter drone-in-a-box could achieve, purely because generating lift passively on its 1650 mm wingspan allows it to fly much longer – up to 2.5 hours depending on mission conditions, plus 30-40 minutes of maximum hover time,” says Diego Ruiz, lead drone operator.

“We have several swappable payloads – not quick release yet but we’re working on that – and we use the Cube Orange+ as our autopilot to enable open-source programming, GCSs and so on, whether for end-users’ testing or commercial operations.”

While the Pathfinder flies on one battery pack, the Starling Hub contains two more, for mechanically swapping one into the UAV when it lands upon the 2.1 m2 landing surface. The swap lasts 30 s, and landing safety is ensured using the UAV’s onboard payload sensor and embedded computer vision (which recognises a QR code visible in both day and night conditions).

“Another interesting point of how we’ve engineered this UAV concerns its wingtip motors,” Ruiz continues. “Those give us more yaw stability, and being so low-profile, our V-tail is about 30° shallower than that of most V-tail drones.

“That combines with the motor arrangement to give us super smooth turns, and hence really balanced, stable circling in, say, loitering situations where you’re tracking targeted trespassers near critical infrastructure, or circling a mountain or plant to capture a really precise digital twin of it.”

For environmental protection, either wing and the tail each feature a servo-lockable hinge, which lock to maintain the flight profile during missions, and unlock so that the Hub’s electromechanical hatch doors can lift them into their upright folded position after landing (slightly reminiscent of the Grumman F-4F Wildcat). The wings and tail are spring-loaded to fall back down into flight configuration when not pushed upwards by the doors.

The Hub integrates a climate-controlled environment, as well as multiple temperature and humidity sensors (together with cellular or satcom telemetry links upon request) to assess the likely health of the UAV within, as well as four cameras for direct visual monitoring atop and around the station. Additionally, a weather station tracks local temperature, humidity, precipitation and wind activity.

For end-users interested in edge processing of routine survey data, the Starling Hub may also integrate an NVidia Jetson Orin Nano Super module.

Summary

In addition to these various examples of unusual approaches to aircraft engineering and operations, it is hard not to take note of the ongoing fanfare around urban air taxi systems. Well over a hundred of these companies are now in operation, and whether they are gathering seed capital, actively manufacturing or undergoing difficulties, each is notably presenting aircraft somewhat different in their architecture.

Some, like EHang and Volocopter, have essentially built large multi-rotors, with cockpits in place of the usual avionics hub. Others, like Joby, Archer and Wisk are utilising tiltrotors on fixed-wing systems, while a few go even further, such as Dufour Aerospace who have successfully engineered tiltwing UAVs (Issue 52) and plan to build crewed eVTOLs in the future using lessons learned from that solution.

Whether the face of passenger aviation will become a mixture of these crafts of different shapes and sizes alongside standard commercial airliners remains to be seen. But the bounty of engineering knowledge gained from these companies’ relentless activities, together with that being accumulated across the UAV world, will doubtless spur continued blooms of imagination across aerospace engineering for the rest of the 21st century.

UPCOMING EVENTS