GPA Seabots 100

Rory Jackson reports on how these systems answer growing calls from port authorities for robotic USVs that can carry out clean-ups as well as survey duties

With most of the world’s cities and a growing proportion of the global economy directly connected to our oceans, it is inevitable that marine territories are not only becoming more polluted but are being exposed to multiple different ecological threats, each needing its own solution.

For instance, litter in canals, estuaries and shorelines can be collected autonomously by a single small boat such as NXInnovation’s NX 100 Enviro USV (issue 48, February/March 2023) or a large vessel acting as the mothership for a team of UUVs and UAVs, as in Subsea-Tech’s SeaCAT UGV (issue 52, October/November 2023).

By contrast, algal blooms and other biological threats can be identified and measured to aid in countermeasures using a USV such as RanMarine’s Wasteshark (issue 11, December 2016/January 2017) or an AUV such as Xylem’s i3XO (issue 42, February/March 2022). Also, chemical spills can be similarly sampled and identified by an uncrewed skimming boat such as that created through the partnership of Sea Machines and the Marine Spill Response Corporation (issue 34, October/November 2020).

Harbours are areas of high overlap between different ecological threats, where litter as well as chemical and biological agents can spill into the waters every day. There is therefore a strong demand among harbour operators for autonomous systems that can monitor and clean their waters in a repeatable, cost-effective and time-efficient manner.

Since its founding in 2019, Spanish autonomous systems manufacturer GPA Seabots has been supplying and customising its USVs to recreational marinas and commercial industrial ports to help keep their waters clean. It has also designed and produced filtering buoys made from microplastics, along with other ecologically minded solutions.

The bulk of its customers are harbour authorities who want a combination of autonomous waste clearing, oil spill cleaning and hydrographic surveys. Three USV designs comprise the company’s port monitoring and restoration solutions, each including the ability to sample for hydrocarbons as well as remove them from water surfaces.

Seabots USVs

GPA Seabots’ principle tool for collecting waste and liquid pollutants is the SB 100 Cleaner, a fully electric catamaran USV built from fibreglass composite and running on a LiFePo4 battery with an estimated lifespan in excess of 2000 cycles. The USV measures 103 x 75 x 55 cm, with a 14 cm draft. It weighs 25 kg empty and can be loaded with up to 12 kg of payload.

The ‘payload’ includes the equipment for cleaning as well as the material gathered during cleaning. The equipment comprises a basket installed between its two catamaran hulls for scooping up litter, and industry-standard oil absorbent pads that can be installed and arranged about the USV in different ways to optimise the removal of petrochemicals from the water.

The company’s data-gathering USV is the SB 100 Pro, a vessel almost identical in size and construction to the Cleaner. Minor differences include a slightly heavier empty weight of 31 kg, an increased draft of 15 cm, and a maximum payload of 15 kg. These give it a maximum endurance of 3 hours, while the Cleaner’s is 3.5 hours.

“The Cleaner was our first prototype, and the lower half of its catamaran shape was designed to fit what we call our ‘pelican mouth’ basket for collecting solid trash from the water’s surface,” explains Javier Sanchez Barchino, manager at GPA Seabots.

“But we also wanted something that would clean oil from water. That’s an underserved use case, but a really important one for protecting marine life around ports and ships where oil spills happen by accident every day.

“We started by putting oil absorbers inside the pelican mouth, or wrapping them horizontally around the USV’s body, but quickly discovered through real-world testing that if you direct your USV into a patch of floating oil, you don’t really catch any oil at all. If anything, you just split the oil in two because of the density of the water you’re pushing before you. So we’ve learned to orient the oil catchers in different ways.

“The Pro meanwhile weighs more than the Cleaner because it carries heavier, more expensive electronics for precise surveying, including more robust navigation and interfacing systems.”

In addition to these two, GPA Seabots has designed, prototyped and demonstrated a larger USV, the Harbot. It was developed after requests from port operators for an uncrewed oil and debris collection solution that could operate completely autonomously, without needing human employees to perform any of its pre or post-cleaning maintenance.

At the moment, the Harbot exists only in a prototyped and demonstrated form, officially it is still “in development” and not yet offered commercially (nor are its specifications available), as the two SB 100s are, but it remains a focal point for GPA Seabots’ r&d.

Deployment logistics

The decision to design and develop the two SB 100s as small vehicles was driven by requests among customers for something that would be easy to deploy. In addition to harbours having internal and external zones, port authorities and related operators will sometimes have estuaries or lagoons they need cleaned and surveyed. Engineering the USVs to be deployable by an individual and transportable between job locations using a small road vehicle was therefore an early target.

“It’s just as important to have the robot work autonomously though,” Barchino says. “Small size and autonomy make customers’ lives easier, as does making the USVs battery-powered. We reduce customers’ operating costs by around 80% by not needing fuel, cranes or hands-on remote control, as larger or less autonomous USVs might.

“Logistics contributes massively to the cost barrier of adopting and using uncrewed vehicles. Imagine having to move a 10 m-long USV over 100 km from a harbour warehouse to a lagoon once a week and you get an idea of why some harbour owners still hesitate to use uncrewed systems – something like that can cost €1000 per road journey alone.

“With our systems, they can just drive the SB 100 to the launch point, drop it in the water and program its waypoints. The USV then cleans or surveys autonomously while the operator just monitors it, and then the customer lifts it from the water at its predefined mission endpoint, loads it into the vehicle and drives it home.”

The typical set-up for oil cleaning uses two plastic booms extending forwards from the Cleaner in a V-shape, with plastic ‘container’ floats – solid objects that shepherd and contain the oil in the space between them – fastened along the lengths of the booms. Their tips extend about 1.5 m apart from one another at the frontal, furthest point of their reach.

“Having the arms reaching outwards like that means we can scoop and contain puddles of oil from the surface instead of just splitting and pushing them away,” Barchino explains.

“That works for most spills in ports or marinas, which typically occur from things like when repair personnel working on yachts accidentally knock tins of chemicals into the water. But if there’s a larger spill, we can arrange the equipment differently, for instance spreading the absorbers in a wider fan, using more absorbers on a USV at once, or using more than one USV in a group, mesh or swarm formation to cover a wider diameter of oil.”

The litter basket is typically also placed between the catamaran hulls, with one to three absorber towels installed inside it. The containers can therefore catch wider patches of oil and funnel them into a more narrow shape, while the USV navigates into that narrowed patch so that the oil can be caught and suspended in the absorbers. An extra container can be wrapped around the back of the basket for catching and containing any droplets that are not absorbed.

If however the USV’s job is only to collect litter, GPA Seabots recommends removing the container floats and absorbers to minimise drag in the water and maximise the amount of room for litter inside the basket. Different baskets are also available, including some with plastic bristles around the mouth to prevent litter from floating back out into the harbour.

CONOPS for cleaning

While MWIR cameras are increasingly popular for detecting spilled or leaking hydrocarbons, the presence of oil in harbours is often easily detected visually, particularly in Spanish ports where bright sunlight will reflect off the oil with a distinctive shimmer, distinguishing it from the surrounding water. GNSS waypoints for cleaning paths can therefore be plotted based on visual estimates made from a ship or the quayside.

While positioning the containers and absorbers at approximately surface level helps to catch as much oil as possible, rarely will a USV capture all the fluid in a single pass, as the current will carry stray droplets of oil over and under the containers, or thread them through the limited spaces between the containers and absorbers.

So in most hydrocarbon-focused operations, it will make repeated passes over an area to give assurance that all the chemicals have been collected and that the water is clean.

Also, while the Cleaner is moving, an FPV camera installed on the front will stream live video back to the operator’s GCS, from which they can track that the USV is successfully scooping up oil and litter. Between the two forms of pollutant, oil clean-ups bear closer FPV monitoring as the spills are more sporadic, accident-driven occurrences, whereas litter build-ups are more predictable.

“Marina Barcelona 92 for instance, a major marina for superyachts, is committed to sustainability and innovation in environmental matters, and uses at least one of our Cleaners for 2-3 hours a day to keep the water clean for its clients,” Barchino says.

As mentioned, GPA Seabots can deploy multiple USVs at once if the situation demands it. This tends to happen more often in larger ports, such as the commercial harbours or luxury marinas found in Spain where spill quantities or the urgency of containment can be greater.

In addition to two or more USVs moving in a swathe over a patch of oil, its containment can be performed in which the USVs either encircle a spill and enclose their absorbers around it, or move in a corkscrew pattern around it, to minimise the chances of any chemical droplets being pushed outside a given area and potentially towards bystanders.

“Also, the FPV camera is useful for routine surveys, such as visually inspecting underneath bridges or drains, where regular boats cannot go,” Barchino says. “It’s also valued by our operators because they don’t lose visual tracking of where the USV is, even when it ‘disappears’ between boats.

“Many port authorities have stressed to us that they always want to be able to clean every feasible inch of their ports, even between all the moored boats. That’s hard for human cleaners, but they don’t ever want to lose track of where the USV is, so getting a constant video feed, over 2.4 GHz wi-fi, is key.”

He adds that such customers similarly want the USVs to survey every last nook and cranny of their harbours, even when using multi-beam echo sounders that don’t need to go right up to a quay’s walls.

Notably, survey sensors and cleaning equipment can be installed together, with some configurations of the Cleaner having a water quality measuring sonde fitted in front of the litter basket. The most sought-after data are typically measurements of conductivity, temperature and salinity in harbour waters.

“But surveys are just as important as regular cleaning because nowadays, port owners really want to create biodiversity inside their waters, and understanding water quality is key to predicting whether marine life will flourish in a harbour,” Barchino says.

“So as well as doing hydrographic surveys by integrating echo sounders and sidescan sonars, we’ve also integrated things like 2 litre electrically powered water samplers and underwater cameras, to directly inspect the biodiversity and the parameters of the water that can influence that.”

On top of these, other payloads including sound velocity profilers, sub-bottom profilers and water quality measurement tools have been integrated, often on the basis of each harbour authority having its own inventory of familiar survey devices it prefers to keep using with its Seabots.

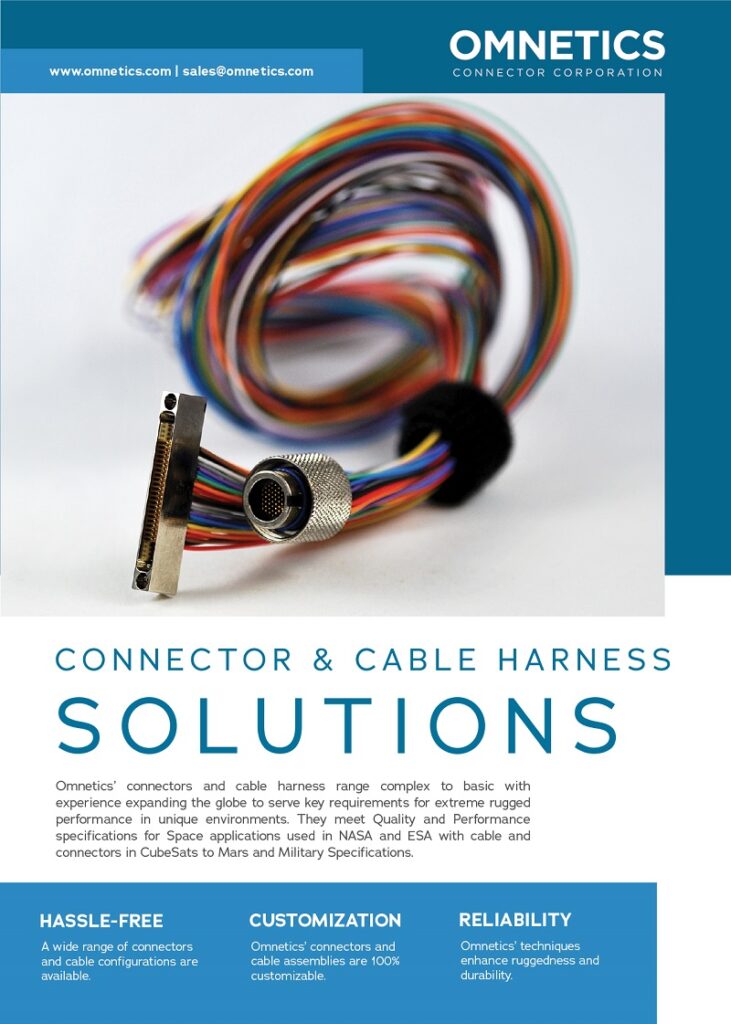

To enable that, payload sensors are flexibly integrated via the Black Box, GPA Seabots’ proprietary central control unit. This features a range of USB, Ethernet, and serial (including RS-232 and RS-422) ports for communicating with different electronics, as well as 5, 12 and 24 V ports for power distribution from a central transformer.

“If there’s a new sensor someone wants us to integrate with a new connector, we can easily modify the Black Box to accept that,” Barchino adds. “Other USV manufacturers’ main computers are often closed systems locked into specific payloads, but we’ve found that keeping our system open and flexible to new payload integrations is indispensable for our harbour clients.”

Inside the Black Box is a 10th-generation Intel i7 CPU with 32 Gbytes of RAM running on Windows 10. The enclosure is ruggedised and sealed to prevent salt water ingress, while the top of the Black Box integrates a cooling fan for blowing air into the housing’s dorsal heat sink.

Although the controller unit can be customised, GPA Seabots does not offer versions without this fan. Given the heat in the Mediterranean and elsewhere, such as the Middle East, failing to cool the USVs’ computers against an ambient heat of up to 50 oC and the additional heat produced by the PC would result in the system shutting down.

All the USVs are optimised for moving at 1 m/s (3.6 kph), an ideal speed for gathering waste and data without producing wave wakes that would spread trash and oil around, or splashing that would interfere with data integrity. That speed is achieved through dual Blue Robotics T200 electric thrusters, which Barchino says are a vital component for saving on part and assembly costs, as they are a mass-produced, turnkey solution for uncrewed aquatic vehicles.

Oil, battery and solar power

Each absorber on the Cleaner has a maximum capacity of 6 litres of oil, with an actual recommended capacity of 4 litres, and can be used just once or twice before having to be disposed of in a special container. Each USV can therefore be sent to capture up to 12 litres of spills at a time before needing to return to its operator for maintenance.

The litter basket meanwhile can carry up to 30 litres of refuse, but as litter will not compress together neatly, both the Cleaner and Harbot integrate a weight sensor to detect when the basket is reaching capacity.

Although units sold and hours worked by the Cleaner far outstrip those of the Harbot, the Harbot and its operating concept deviate most from the Cleaner when it comes to post-operational maintenance.

For instance, while the Cleaner needs to undergo a battery swap or plug-in recharging to replenish its energy store, the Harbot has solar cells on top of its dome-shaped roof to recharge while stationary.

Ideally, each Harbot would spend one or more days sitting still and recharging slowly between cleaning operations (the speed of charging increasing with but not depending on direct sunlight), rendering human interaction and wired connections unnecessary for charging the vehicle. It would also eliminate much of the need for a human to carry the USV in and out of the water.

“The dome-shaped solar roof maximises its passive charging rate, and we also have an inductive charging receptacle in the design concept so that it can navigate to an emitter for wireless charging of its batteries if it runs out of energy before it can complete a mission or return to its mooring location,” Barchino says.

One less certain area is how the Harbot’s litter basket, oil containers and oil absorbers would be removed and replaced between outings, although Barchino notes that automated systems for handling these would be developed if the right investor or partner was found to bring the project forward.

In the meantime, litter tends to be removed manually from the Harbot’s baskets, as with the Cleaner, and most harbours tend to store that litter in specified containers. This keeps a running tally of how much litter the USVs are gathering, to confirm that they are working correctly and assess how much they are removing from the water compared with targets, or with amounts removed by human workers in the past.

Oil is removed and set aside from the absorbers in a similar manner, for comparable assessment reasons and also because of the chemical hazards that hydrocarbons pose. PPE is worn as a requirement during this phase.

“As a final step, both the survey and sanitation USVs must be thoroughly cleaned with mineral water,” Barchino says. “These robots operate in salt water, and salt corrosion is the enemy of connectors and electronics housings.

“The SB 100s are IP 65-rated, but even so, we train our customers in good practices to get a decent lifespan out of them. That includes cleaning with mineral water and storing them in places that aren’t too hot or too cold to prevent thermal wear over time.”

Future plans

GPA Seabots has an ambition to create a bigger USV than the Harbot, given the right partnership and programme.

A bigger USV would mean dedicated space for GPUs performing onboard AI processing of visual, Lidar and radar data, to produce an intelligent harbour security patrol solution the company could couple with its solutions for clean-ups and underwater surveys. Barchino names these three areas – security, clean-ups and surveying – as the biggest causes of concern among port authorities.

“We don’t want to develop such a technology for its own sake though,” he notes. “Commercial success in uncrewed systems comes from shaping your r&d around specific customer requirements.

“But there’s been a surge in demand for professional USVs over the past few years, analogous to that in commercial UAVs and their influence on airspace regulations. We anticipate that maritime regulations will evolve similarly, making the use of USVs and investing in their development a normal part of owning and operating harbour infrastructure in the future.”

Specifications

SB 100 Cleaner

- Catamaran

- Lithium iron phosphate battery

- 103 x 75 x 55 cm

- Empty weight: 28 kg

- Payload capacity: 12 kg

- Operating speed: 1 m/s

- Maximum speed: 2 m/s

- Maximum power: 700 W

- Endurance: 3.5 hours

- Battery capacity: 30 Ah

SB 100 Pro

- Catamaran

- Lithium iron phosphate battery

- 103 x 75 x 55 cm

- Empty weight: 31 kg

- Payload capacity: 15 kg

- Operating speed: 1 m/s

- Maximum speed: 2 m/s

- Maximum power: 700 W

- Endurance: 3 hours

- Battery capacity: 30 Ah

UPCOMING EVENTS