Tekever AR3

(All images courtesy of Tekever)

Front-line innovation

They say that necessity is the mother of invention, and Peter Donaldson discovers why for one company supplying UAVs to Ukraine

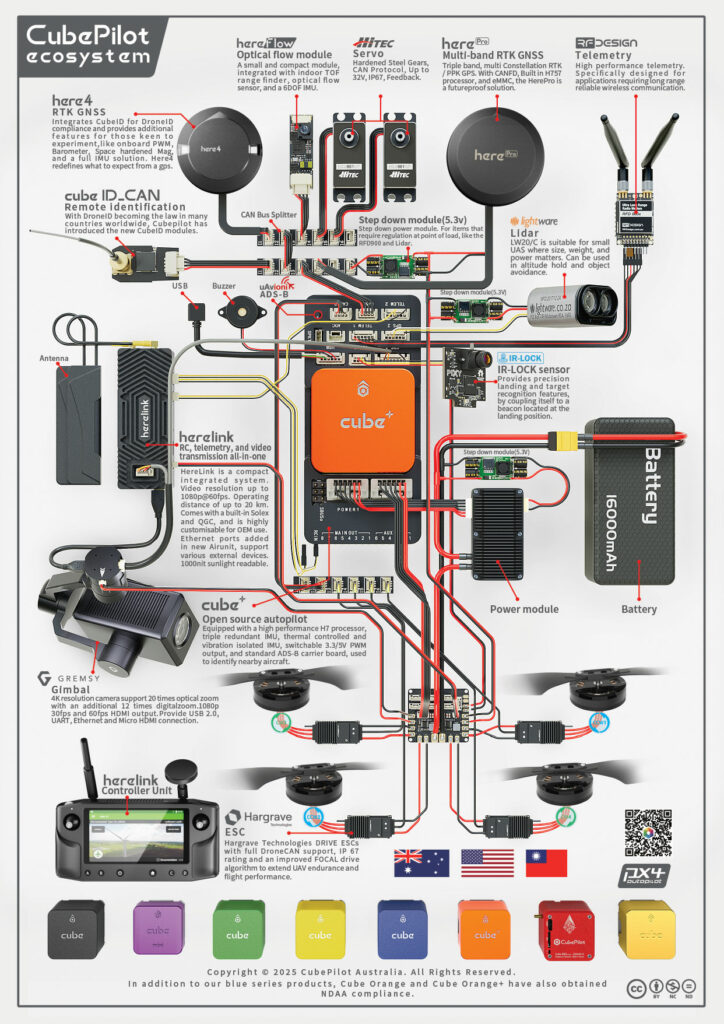

There is nothing like a modern high-intensity conflict for shaping military technologies, and the war in Ukraine has impacted uncrewed systems like no other. Tekever’s AR3 Evolution – the latest iteration of the Portuguese company’s 25 kg fixed-wing, medium-altitude, long-endurance UAV system with optional VTOL capability – is a case in point. Earlier versions have served with the Ukrainian armed forces since 2022 as intelligence, surveillance and target acquisition assets. However, the rapidly evolving realities of operations against Russia, a re-emerged superpower, have driven a fundamental re-engineering of the air vehicle and the system as a whole to emphasise modularity, rapid reconfiguration, survivability, endurance and multi-platform coordination.

Ricardo Mendes and Tiago Nunes, Tekever CEO and platforms director, respectively, explain the drivers and processes that have pushed and continue to push the development of the AR3 Evolution, referred to internally as the Mk9.

Referencing earlier versions of the system, Mendes says that it has built on operational experience with multiple customers in diverse markets. “I would say the main driver for development and maturity has been its usage in Ukraine.”

Integrated air defences

Russia operates a multi-layered integrated air defence system that is widely acknowledged as the best in the world. Its ground-based air defences alone consist of radars, electronic warfare systems and electro-optical (EO) sensors networked with weapons whose effective range extends from hundreds of kilometres down to hundreds of metres or less, with overlapping, mutually supporting engagement envelopes. These are supported by jet fighters, airborne warning and control, and dedicated electronic warfare aircraft, as well as large and growing fleets of uncrewed aerial vehicles of many kinds.

Since shipping the first systems in spring 2022, the AR3 has been through more than 100 incremental iterations. “That is a lot of learning and adaptation, so what we wanted to do with the Mk9 was catch up – from an engineering point of view – and consolidate the changes into a new version that captures everything we learned in these three years.”

While these lessons apply to the platform, they also go far beyond, he argues. “There is also fundamental learning that has nothing specifically to do with the platform, although it fundamentally impacts how it is designed. This is the amount of variability that you face in missions and the flexibility you need from the system, which is tremendous and constant.”

He cautions that while people expect a very rapid development cycle, they also expect it to slow down, when in fact the opposite happens. “You need to create a system that is prepared for that.”

Mendes also emphasises that the complexity of the mission keeps growing such that no single platform configuration is adequate, and therefore the problem must be resolved by the system as a whole. Different aircraft within the same system must carry different payloads and configurations, and these setups can change rapidly, even within the same day. The system must be flexible and allow quick reconfiguration in the field, in minutes or seconds, not hours, he says.

Points of flexibility

These two factors – the accelerating rate of change and growing complexity – are the main design drivers for the entire system, Mendes says, which have resulted in “four main points of flexibility,” as he calls them, although he expects more to emerge soon.

The first of these is payloads. “It’s very common in these systems to be able to swap payloads easily, and we can now even use Group 3 payloads on a Group 2 platform, which is really exciting,” he says.

Second is the deployment mechanism. “Being able to switch between pure fixed-wing and VTOL configurations is critical. We already do this with earlier versions, but with the Mk9, we’re doing it much better – and we have to keep optimising it.”

The third point of flexibility involves the propulsion system, namely the ability to swap between different combustion engines or electric configurations quickly. “Sometimes you’re optimising for altitude, sometimes for speed, endurance, or just simplicity – and you might need all of that in the same mission.

“You could have one aircraft acting as a communications node – optimised for endurance, another carrying a SAR [synthetic aperture radar] payload – optimised for altitude, and another using an optical payload with yet another requirement, all at the same time.”

Fourth and, for the moment, last is communications. Here, the UAV systems are usually part of a bigger mission network, either acting as a relay or receiving comms. The need is to change communications setups easily, swapping out satcom and line-of-sight radios very quickly.

Fractionated payloads

“One of the things we’re working on right now is what we’re calling fractionated payloads – meaning, for example, complex radio frequency [RF] payloads where multiple aircraft together form a single node. A single aircraft, or even two or three, on their own can’t accomplish much. You need several systems in the air, communicating and exchanging RF data with each other, for the payload to function properly. The system is greater than the sum of its parts and each aircraft platform is just a part of that system,” Mendes explains.

This kind of system might be used for the detection, identification and geolocation of hostile emitters, for example, and even what can be thought of as deception missions. “In some of them, you are shaping the RF perception of the enemy,” he says, “basically creating an RF image for the other side. And for that you need multiple nodes doing different things at the same time in a highly coordinated way.”

Naturally, this means that each of several aircraft might have a very different configuration from each of the others with which it is operating, and all must be easy to manage from the same ground control station (GCS).

In another example, it’s common to run missions using a SAR payload together with optical and infrared sensors. This involves using Group 3 sensors on a Group 2 platform, so the sensors must be distributed among multiple aircraft. For example, one aircraft might have a SAR and a smaller gimbal, while a second carries a larger gimbal, and a third machine serves as a relay linking the two, particularly if the mission requires them to work at long distances from the launch point, which can mean 200 km away or more, he says.

“For us, this isn’t some future potential – this is daily reality! We’ve been adapting existing platforms like the AR3 and earlier versions to do this, even though they weren’t originally designed for it. The Mk9, however, was built from the ground up with this in mind, making everything much simpler for the operator.”

The headline design goals for the aircraft were to increase endurance and payload while reducing the radar and acoustic signatures beyond those of its predecessor. They also wanted to speed up deployment, and now the machine can go ‘from box to air’ in five minutes once the operator is trained up; the latter process taking purportedly no more than five days. The VTOL capability, a removable option before, is now hot swappable. Finally, the entire system is transportable in a pick-up truck.

Configuration changes

One thing that is instantly noticeable is that the aircraft looks very different. The main engine and propeller have been moved from its predecessor’s rear-mounted pusher layout to a tractor configuration placed on the nose. The tail has also changed; where the previous AR3 had a horizontal stabiliser with a vertical surface on each end in a fixed-wing configuration, and a V-tail in VTOL configuration, the Mk9 has an inverted V-tail in both configurations. The VTOL module attachment scheme has also changed from a hard-point under each wing to a plug between each end of the wing centre section and each outboard section, more of which we detail later.

Much thought and input went into the design, but one of the key takeaways was that a more efficient powerplant installation was needed, leading them to the change from a pusher to a tractor configuration. “This gives the propeller less turbulent air, which increases efficiency and reduces the acoustic signature compared with the previous version,” Nunes explains.

The aircraft was also designed from the start with VTOL in mind, and the new configuration allows for much more automation compared with the previous version. This is the result of two key decisions. First, they inverted the tail so that it now forms part of the undercarriage during take-off and landing in VTOL mode. The second was a sharp focus on weight reduction. “The aircraft architecture – electronics and hardware – is now very tightly integrated, allowing us to save weight and use that margin for more fuel, which boosts endurance,” he says.

Another important weight-saving measure involved eliminating the need for a gimbal retracting mechanism while still providing protection for payloads during both parachute recovery and VTOL landing. In the first case, the parachute gently sets the aircraft down belly up, while in the second it comes down on the specially reinforced tips of the V-tail and on a pair of detachable legs that act as the forward landing gear, leaving the gimbal clear of the ground.

The combination of a more efficient main powerplant, aerodynamic refinements and the weight-saving measures have resulted in endurance increases of 70% in VTOL mode and 40% in fixed-wing-only mode, and 50% more payload capacity.

Stealth enhancement

To reduce the AR3’s radar cross-section (RCS), Tekever undertook a multichannel analysis of non-linear interactions (MCANI) programme. The MCANI technique is used to analyse and predict how radar signals interact with a stealth aircraft’s surface, especially when multiple, complex reflections and scattering events happen concurrently. These include non-linear and multipath effects, such as multiple bounces between surfaces. Multichannel analysis refers to measuring or simulating multiple interaction pathways simultaneously to better predict and minimise the aircraft’s detectability.

Tekever’s RCS-reduction effort began with extensive simulation work focused on the aircraft’s design, particularly its silhouette, airframe and wing geometry, according to Nunes. “There are a lot of design techniques you can apply to minimise radar reflections, and we’ve leveraged those heavily. We also prioritised material selection. Certain coatings and structural covers can significantly reduce the RCS, so we experimented with different options to find the most effective combinations. Between simulation-based design refinement, anechoic chamber testing and advanced materials, we’ve managed to drastically cut the radar signature,” he says.

One of the most important insights they gained from this process, according to Nunes, is that payload changes have huge impact on the RCS. “Early on, we didn’t know exactly which payloads would be used, so the airframe wasn’t fully optimised for them. Now, based on operational data, we’ve refined the entire system – both design and materials – to account for these factors.”

That led to significant improvements, he adds, from structural tweaks to new radar-absorbent materials. Over the past few years, the company has launched studies into RCS-reducing materials.

“With the Mk9, we’ve invested heavily in design-for-survivability, with RCS reduction as a core pillar. Beyond lab simulations and testing, we’ve had the unique advantage of validating performance in the most demanding real-world environment possible – Ukraine. What started as an airframe-focused effort has now evolved into a holistic system optimisation, and we’re very happy with the result.”

One notable compromise involves the V-tail design, which presented a stealth optimisation challenge. Ideal low-observable configurations require strict edge alignment to minimise the radar profile, but the V-tail inherently prevents perfect edge alignment with the wings. The V-tail configuration was selected primarily for weight savings in relation to the landing gear system – a deliberate prioritisation of structural efficiency over signature reduction.

However, careful selection and use of materials helps here. “Basically, if you’re more exposed in a certain area, you need to use materials that protect you more from that point of view. But like everything in engineering work, it’s a matter of trade-offs.”

One area in which they had to be particularly careful is the use of carbon fibre, which is a strong reflector of radar energy because of its electrical conductivity, while potential alternatives such as glass and aramid fibres are better in this respect but have lower strength-to-weight ratios.

Mitigation of the reflectivity of structural materials is one of the key applications of radar-absorbing coatings, and this is an active area of r&d for Tekever, although it is inevitably a sensitive subject. “There are very interesting new types of materials coming out of r&d that we are already experimenting with,” says Nunes. “It is too soon to be sure how they will perform operationally, but from a technical point of view in the lab, they’re very promising.”

Mendes says that the material they are working on is at technology-readiness level 7, adding that “metamaterials are a fundamental area of research for us right now.”

In terms of their overall approach to structure and materials, they are naturally still focused on advanced composites, but with the Mk9, they have taken everything they have learned and pushed it further.

Nunes emphasises that they are using the best composite materials available; some developed locally, some sourced from further afield. He adds that it’s not just about the materials – it’s about applying hard-won experience to simplify the design, which is tricky because true simplicity in aerospace structures is counterintuitively complex to achieve.

Autoclave-cured prepregs

Every part of the aircraft – the wings, fuselage and other structural components – has been optimised to eliminate unnecessary weight and complexity, he says. Tekever is working with autoclave-cured carbon fibre pre-pregs because they provide the best fibre–resin ratio. But material choice is commensurate with design philosophy, and there they have focused on putting material only where it’s needed.

Carbon fibre is used extensively, but it is not always appropriate. “Where we need RF transparency, we’ll use glass fibre. For components that need impact resistance or specific wear properties, we’ll go with aramid. Every material decision is driven by the function of the part in question.”

When it comes to resins, they consider them as elements of the pre-preg material, which they judge in the light of the performance they need from the composite rather than the resin itself. “So, it needs to work with our autoclaves, with the pressure and the temperatures we are using.”

Flexible, modular propulsion

The flexibility that Tekever is engineering into the AR3 Mk9 also extends to propulsion systems. Nunes explains that the company develops its own powerplants based on commercially available engine cores and energy sources. Their approach focuses on mission-specific optimisation, which can mean prioritising speed, altitude or endurance, for example. Each requirement demands different power characteristics, so they tailor the system accordingly, balancing performance with fuel efficiency.

This has led Tekever to support multiple energy sources to meet operational needs, including batteries and liquid fuels, with the latter encompassing gasoline and heavy fuels such as JP5, JP8 and Jet-A.

Tekever has a high level of vertical integration, which extends to the ability to customise solutions around commercially available engine cores, evaluating and validating them and then developing in-house all the ancillary systems, such as ignition, fuel injection and engine management systems. Core engine manufacturers they have been working with include 3W, Desert Aircraft, Hirth and ZDZ. Deep system integration knowledge enables the engineering team to match powerplants to operational requirements precisely, according to Mendes.

Payload support is closely tied to the selected propulsion configuration, Nunes explains. “The amount of electrical power available depends on the power plant chosen for a specific setup,” he says. For standard intelligence, surveillance and reconnaissance (ISR) configurations with high-end sensors, the platform provides up to 500 W of electrical power – enough to support even some Group 3 payloads, not just those typically found on Group 2 aircraft.

On the data side, the system architecture is Ethernet-based, offering significant flexibility. “As long as the payload communicates over Ethernet, integration is straightforward,” he says. The platform also supplies various voltages (28, 24, 12 and 5 V) over Ethernet lines, with additional support for serial and Controller Area Network (CAN) bus interfaces.

VTOL hot swaps

The other key element of the propulsion system is the hot-swappable VTOL capability, so called because the entire system is designed for seamless reconfiguration in the field. Configured for fixed-wing only flight, the aircraft has all the essential avionics, flight computers and control logic for both modes of flight, including launch and recovery, integrated into the fuselage. All that is missing for VTOL flight is the arms, which house everything needed for vertical flight: propellers, motors, speed controllers, and batteries – so all the energy for vertical flight is stored in the arms. When the operator attaches them, the flight control computer recognises that they are connected and automatically enables the VTOL modes, while removing them prompts the computer to revert to pure fixed-wing flight control logic, with no manual recalibration required, Nunes explains.

The system is truly modular in that the wings are built in three sections, namely the central section and the two outer sections. To install the VTOL modules, the operator simply detaches each outer wing section from the centre section, slots each module into its place, and finally reattaches each outer section to the mounting point on the outer side of each VTOL module. The entire modification process can be carried out while the aircraft is powered up.

The wing centre section module is rapidly swappable in its own right, and made that way to house the aircraft’s communications suite so that it can be rapidly reconfigured between missions. If there is a need to swap satcom systems between satcom and line-of-sight ratios, or between Silvus and Persistent line-of-sight radios, for example, all that is necessary is to change the wing centre section, regardless of whether the mission uses VTOL.

Mendes stresses that the difference in endurance between the VTOL and fixed-wing-only configurations is highly significant. “As much as we like the simplicity of just taking off vertically, going to do the mission, coming back and landing, sometimes we really need the extreme endurance,” he says. “With full capable payload, we are at 12 hours in the VTOL configuration; without VTOL, we are past 18 hours,” he notes, emphasising that these are real operational numbers, not lab numbers.

In both cases, these figures refer to aircraft that are optimised for operational capability with significant sensor suites, not machines cleaned up to stretch their endurance. “If we were talking about a configuration optimised for endurance, we would be beyond 22 hours in a non-VTOL configuration, which can be very useful for a relay mission.”

That typical six hours of extra endurance for the non-VTOL configuration can be very significant, Mendes stresses. “We see a lot of systems that are just VTOL, and that’s a tremendous limitation on the system. So, we thought the best of both worlds would be to have the option of being either pure fixed-wing or pure VTOL.”

Beacon landings

The VTOL capability also brings the potential for precision landings in confined spaces, difficult terrain and onto moving vessels. In VTOL mode, the AR3 Mk9 needs only five square meters of relatively flat surface to land on, whether that’s on a ship’s deck, a mountain ridge or even the roof of a building.

The standard approach – relying solely on GPS – can provide reasonable accuracy under ideal conditions, but in GNSS-denied or contested environments, that’s simply not an option, says Nunes. This is where the company’s Lidar-beacon-based landing system, supported by onboard cameras, comes into play. The aircraft first navigates to a rough landing position, then detects and locks onto the beacon, guiding itself down with precision. To land on a moving vessel, the aircraft matches its forward speed with the ship during descent, achieving zero relative velocity, enabling landings with sub-meter accuracy, even in rough seas, he explains.

Mendes notes that this precision landing system represents an ongoing, multidisciplinary initiative that brings together teams from airframe design, payload integration, artificial intelligence (AI), and data processing and autopilot development.

The system can use visual aids from onboard cameras, Lidar, RF positioning and GPS/visual GPS, he says, processed in real time to build a precise relative position fix. Aided by AI, data fusion happens at the hardware level, with a dedicated computing module weighing inputs from each sensor based on environmental conditions and mission requirements. The output of the fusion process is the ‘best’ estimate of the vehicle’s state, which the autopilot uses to control the landing.

“These best estimates are based on all the inputs you have, and machine learning is really important because you need to consider past experience based on those inputs,” he says. “It’s not a direct application of rules.”

Threat avoidance

As well as the precision landing system, AR3 Evolution’s sensors also contribute more general situational awareness functions needed for beyond-visual-line-of-sight operations, including the avoidance of obstacles, other air traffic and, in war zones, threats. Of the several technologies available, Tekever is most advanced with visual-based detection algorithms for AR3.

Nunes says that AR3’s cameras look all around, not just forward, because of the threat from hostile drones sneaking up on it, either to engineer a collision or to launch a weapon at it. “We have already deployed mechanisms to avoid that, using visual detections and evasive manoeuvres. We are working with acoustic and radar technologies as well for detect-and-avoid solutions for ‘non-cooperative’ airspace users.”

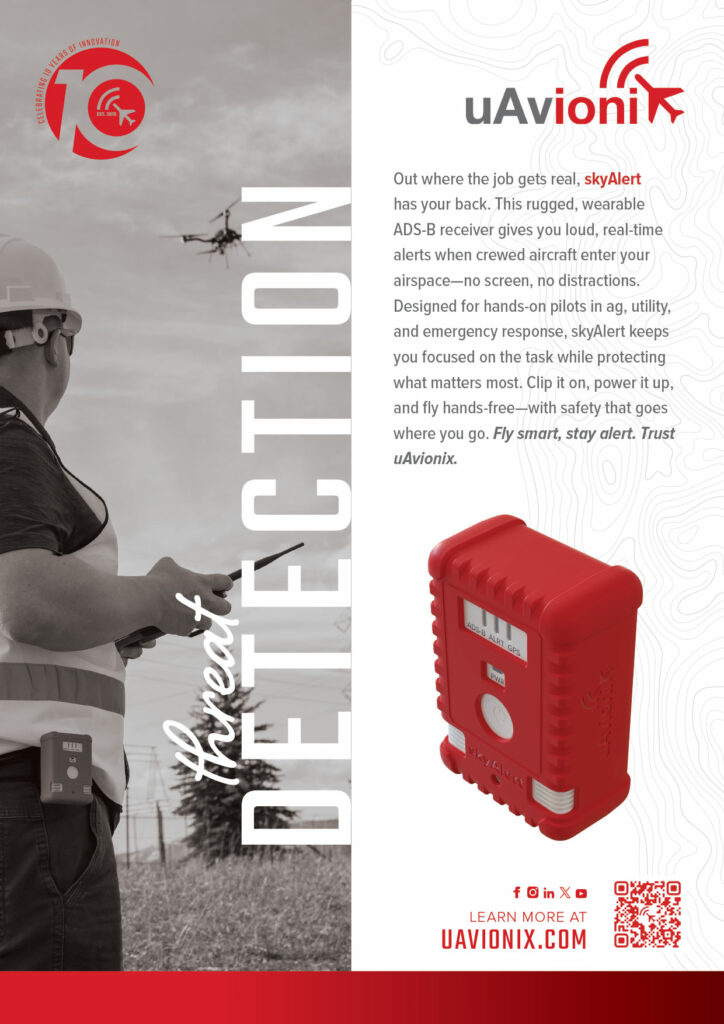

This is in addition to the integration of collaborative systems including ADS-B and transponder signals, he says.

In-house autopilot

The autopilot itself is an in-house development. Throughout the entire programme, as a matter of course, they were constantly asking themselves whether it would be better to buy an existing component or subsystem or to develop their own. They went down the in-house development route with the autopilot because they needed some very specific behaviours, and being vertically integrated made it more efficient for them to bring in their own multidisciplinary team to do the job.

“Having this ecosystem working together to deliver a system brings much more value than just going out to the market and buying something,” he emphasises.

The decision also reflected where Tekever had come from. “We were a software company way before we started building aircraft and so, for us, it was only natural to build the intelligence engine of the system – the autopilot.”

Returning to specific behaviours, he explains that to succeed with deep integration of visual-based navigation or other alternative means of location awareness – and to do swarming, for example, at a very deep level so you can execute different parts of a mission with different systems – you have much more freedom if you control the autopilot.

The missions for which Tekever is developing the AR3 create a unique engineering challenge. In long-range ISR operations, resilience and endurance are paramount. While most autopilot manufacturers focus on optimising for high-volume, short-range systems like quadcopters, Tekever is faced with delivering capabilities that were traditionally only possible with much larger platforms, which it now achieves through networked Group 2 systems, he explains.

This demands an integrated approach. Off-the-shelf solutions aren’t designed for these requirements, so they can’t handle the complexities of distributed missions where a single operator manages multiple aircraft simultaneously. With the operator experience, for example, he stresses that just stitching together disparate interfaces is inadequate. Instead, it is essential to build the entire workflow from the ground up, ensuring seamless control across platforms while simplifying the operator’s task load. That level of optimisation is possible only when the autopilot, GCS and mission logic are co-developed as a unified system.

Critical split

In selecting the core computer technology on which all of this is based, they split it into the critical and non-critical systems. “The critical systems are everything that flies the aircraft, and they are subject to a lot more regulatory constraints in the sense that you need stability for your safety cases,” he says. “So, all of that needs to be captured and relatively stable in terms of versioning of the hardware and software.”

There is, however, a lot more leeway around the non-safety-critical systems, such as those associated with most payloads, for example. “They can improve your performance, but they cannot endanger your flight envelope.”

This means that they can, and do, use the latest and greatest hardware. “Every additional piece of compute power you can get for the same input of energy is fundamental because that’s where you’re running all your intense processing for all the payloads, all the fusion engines and everything else that is important from a payload point of view, and it also informs the autopilot and the flight control systems.”

Here, it is important to point out that non-critical systems can make requests of the autopilot, which then decides whether it can carry them out safely.

The surfaces that control fixed wing flight – ailerons on the wings and ‘ruddervators’ on the V-tail – have redundant servo actuators, continuing the policy implemented on all Tekever UAVs, says Mendes. “We are carrying very expensive payloads, so we need to be fully redundant on everything we can.”

Unlike its AR5 sibling, the AR3 relies on a single engine, meaning that redundancy at that level isn’t an option; however, in such cases, the policy is to keep using better and better components. “There’s a balance between really partnering deeply with your supply chain, while at the same time keeping resilience in the supply chain by using multiple suppliers,” he notes. On servos, for example, they work closely with Volz but also use other suppliers.

Nunes adds that design and component selection for critical avionics, such as control system components, are driven by failure analysis. “We know there are a lot of servos that are not designed for aviation, so we spend a lot of time refining designs to increase our resilience to these small failures. That’s why we design in redundancy.”

He explains that there are many aspects of CAN and other communications protocols that are driven by failure mode analysis to make them more reliable. Coupled with redundancy from the power regulator in the electronics extending through the power and control lines to the actuators, this will increase the reliability of the system, so Tekever’s flight control systems are designed this way.

The engineering team also puts a lot of effort into validating actuators, choosing the best they can find and then conducting rigorous tests to determine the mean time between failures of each. “And we find Volz to be one of the best on the market.”

Redundancy inevitably adds cost, weight and complexity to the system, but that is one of the perennial engineering trade-offs, as Nunes admits. “There is more wiring in the wings and the tail than I would like, but it pays off because it increases the reliability of the system.”

Denied environments

Navigation and communication in an environment in which the adversary has a panoply of mobile ground-based and airborne jamming systems is difficult, but Tekever has integrated some technologies to mitigate the problem into the AR3 and is working on more.

For example, they already use controlled reception pattern antennas, which only receive signals coming from certain directions, enabling them to reject ground-based jammers. “But there comes a point where there are too many jammers,” Nunes admits. Airborne and even satellite-based jammers are even more difficult to manage because their signals come from above, just like real GNSS signals.

VBN and SAR navigation

The inertial navigation system can help for short periods, but all such systems are subject to drift. This is where a variety of other techniques, including visual-based navigation (VBN) come in, with some already in use on the AR3. Initial solutions centre on VBN, processing inputs from dedicated or gimbal-mounted EO cameras. The UAV correlates captured imagery with onboard maps to determine position and orientation. However, VBN’s effectiveness is inherently tied to environmental conditions, Mendes explains.

“We’re already processing VBN onboard in real time,” he says, “but it’s limited – we are heavily dependent on good visual inputs, so we are extending VBN to work with thermal imagery.”

Thermal navigation introduces challenges in that the lower information density in thermal imagery complicates feature extraction and matching, demanding more sophisticated algorithms to maintain navigation fidelity.

To overcome visual limitations, the team is exploiting its own SAR system – called GAMASAR – not just for imaging but also for positioning. Although SAR is inherently independent of visibility and weather conditions, enabling persistent navigation through clouds, smoke or darkness, SAR’s active emission signature introduces significant operational risks.

“SAR transmission bursts disclose your location,” Mendes notes. “Operational use must be tightly controlled to avoid compromising mission security.”

Because the company owns the full SAR hardware and software stack, they can customise its use flexibly. Importantly, SAR sensors inherently include a receive chain, essentially functioning as software-defined radios. This dual-use capability allows the UAV to perform passive RF sensing in addition to active radar imaging.

In addition to its own GAMASAR, Tekever has also integrated IMSAR’s NSP-3 on the AR3 Mk9. In this installation, the sensor sweeps across the aircraft’s track from left to right. Advantages of this include enabling the sensor to cover a larger area in a single pass and instantly switch its gaze from one side to the other to address a target of interest, all potentially while allowing the UAV to remain on the best course to avoid threats.

By passively capturing signals of opportunity, such as commercial wireless, broadcast and even unintended emissions, the system can construct an RF environment map to aid with positioning. This approach is typically not feasible on small UAVs owing to the antenna aperture, RF front-end requirements and the heavy processing load. However, Mendes notes that advancements in onboard compute capability now make real-time RF mapping increasingly practical, even for Group 2 and Group 3 class platforms.

Tekever’s navigation architecture fuses VBN (EO/IR), SAR (active and passive modes), thermal VBN, and RF signals of opportunity into a cohesive localisation framework. Intelligent task management dynamically activates different algorithms and sensing modes depending on mission phase and environmental conditions.

Zero comms missions

In contested environments, communication links are just as vulnerable as navigation systems. Similar to its siblings in the Tekever range, the AR3 is engineered to maintain operational flexibility under electronic attack and, if necessary, to complete missions without any communications at all. Its baseline autonomy enables the UAV both to follow pre-planned waypoints and to react dynamically to sensor inputs and payload data during the mission.

“There are missions – and we’ve done many – where you have to execute a completely radio-silent operation. The system collects data over a valuable target, returns, lands and only then are the data analysed,” Mendes notes.

Such silent missions are not the norm, he emphasises. “What you want is to have everything in real time, that’s the most common type of mission. But in extreme scenarios – like deep penetration missions – you may have no choice but to complete the mission without any active communications.”

Where communication is possible, the system employs a communication management architecture capable of dynamically using whatever links are available at any given time.

“It’s normal for one of our systems to carry six or seven different links,” Mendes explains. These can include low-frequency telemetry and control (TTC) links, higher-frequency links supporting both TTC and payload data, multiple SATCOM options from low-bandwidth Iridium to high-bandwidth KA/KU-band services, 5G cellular networks where available and multiple line-of-sight radios.

Additionally, sophisticated relay architectures extend operational range and resilience. Nunes says that relay setups, where larger UAVs such as the AR5 equipped with high-bandwidth KA/KU links (approaching 10 Mbps), serve as aerial hubs to relay data from smaller UAVs like the AR3.

“You can build a chain of relays across multiple aircraft to maintain connectivity deep into contested zones,” he explains. “Because we’re vertically integrated – we control the aircraft, ground station and tracker antenna design – we have optimised performance. We can routinely achieve 230 km between the ground station and an AR-3 platform.”

Ultimately, the system’s strength lies in its adaptability: modular hardware, intelligent communication management, real-time dynamic bearer selection and the ability to switch to fully autonomous operation when the environment demands it.

Tekever has a large AI department, and the technology contributes to all of the system’s capabilities that rely on data fusion, including the evolving GCS technology and the Atlas web-based system through which the company provides customers with intelligence as a service.

While the GCS is fairly conventional today, the engineering team is working toward a system that is as unintrusive as possible, ideally an AI-enabled ‘co-pilot’ for the operator that, at all times, enables them to understand where the vehicle is, what it’s doing, what stage of its mission is at and what information it’s providing to them. Mendes envisions interacting with the GCS conversationally, and the system giving advice and suggesting different ways of solving the problems facing the operator in real time. “That’s how you build a co-pilot; a co-pilot isn’t just a ‘yes-or-no’ kind of thing.”

Forged in combat, the AR3 Mk9 Evolution represents the distillation of many hard lessons, and it might just represent a step change in UAV capability to operate in the most hostile of environments.

Key specifications

Dimensions: 4.2 m wingspan x 1.96 m length

Cruise speed: 46 knots

Endurance: up to 22 h

MTOW: 25 kg (regulated)

Payload: 6 kg (VTOL with MTOW increased to approx. 28 kg)

Comms range: 230 km

Launch: catapult/VTOL

Recovery: parachute/VTOL

Some key suppliers:

Engines: 3W, Desert Aircraft, Hirth, ZDZ

EO/IR gimbals: Hood Technology, NextVision, Octopus, Tekever, Trillium

Wide-area surveillance: IMSAR, Overwatch Imaging, Tekever

ELINT/SIGINT: CRFS, ESROE, Lifeseeker, Quadsat, Revector

EW: Leonardo

AIS and EPIRB: WTE Wireless Technologies

Airspace deconfliction equipment: uAvionix

Radio communications: Doodle Labs, Microhard, Persistent Systems, Radionor, Silvus, TrellisWare

Satcom: Honeywell VersaWave, Iridium, Starlink

UPCOMING EVENTS