Robotique Occitane ROC-E AIV

(All images courtesy of Robotique Occitane)

L’Autonome en Provence

Factory AGVs and AMRs can be unwieldy and expensive, so one company in the south of France has aimed to make a robot so simple that even small stores and hospitals can use it. Rory Jackson investigates

Building a robot to work among people is one of the most complex challenges for uncrewed systems engineers today. On top of dealing with perennial UGV problems such as real-time obstacle avoidance and efficient path planning, one must design a system that real, thinking, feeling humans must accept in their workplace.

Robots’ movements can be unpredictable or disruptive, potentially posing a collision risk to pedestrians. Their form factors can make them intimidating if too large, or irritating if so small that they get underfoot. They might also be engineered such that they are difficult to interact with or keep track of. Any of these factors may drive even major factory and warehouse owners, looking to cut costs through use of mobile autonomous systems, to look elsewhere.

Robotique Occitane (RobOcc), by contrast, has aimed to engineer its ROC-E autonomous workplace robot to integrate so smoothly and seamlessly among working personnel that it might not only replace the indoor industrial UGVs of large, well-established robotics OEMs working in factories and warehouses, but also find acceptance and uptake among smaller businesses not typically associated with mass automation.

“We are working to deploy ROC-E in stores, exhibition show halls, hotels and hospitals, as well as with logistics and production industries more familiar with this category of robot,” explains Patrick Dehlinger, CEO of RobOcc.

ROC-E is described by the south-of-France-based company as an AIV – an ‘autonomous intelligent vehicle’ – to differentiate it from the automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) long used across large-scale industry and logistics. The system is built upon RobOcc’s NOEME AIV, which itself is a multi-purpose autonomous platform.

“But NOEME is just a vehicle; it has much intelligence in it, but by itself it cannot yet perform any missions. NOEME is for integrators but ROC-E is an autonomous robot purpose-engineered on top of the NOEME vehicle,” Dehlinger explains.

“It is ROC-E that is the customised, finished and turnkey product we deliver to customers for improving their productivity by taking on a wide range of intralogistics and organisational tasks for them. Those tasks depend entirely on the duties they’d like to outsource to the AIV, and the limits of their creativity and ours in terms of designing their payload system to integrate and function atop the robot.”

ROC-E is a battery-electric, wheeled robot, typically measuring 90 x 67 x 46 cm, capable of carrying up to 100 kg and moving at up to 0.8 m/s (2.88 kph). It can operate for up to 10 hours between recharges, with those energy replenishments taking two hours as standard.

Fresh start

Unusually, RobOcc came together as a company after its initial members had departed from another robotics company, largely owing to the latter’s owner.

“I had joined that company as CEO in 2018, ostensibly to help save it, but I left over disagreements and soon after, the owner fired 16 of the company’s 20 employees. In pursuit of a new challenge, we decided to rejoin each other without that owner and launch a new robot project in Q4 2022,” Dehlinger recounts.

“Eight of us working in RobOcc are its co-founders, plus three outside co-founders: one is a factory owner, another owns an electronics design and manufacturing company, and the last is VP in another robotics company – and we share a lot of technical advice with each other while building different robots that don’t directly compete – theirs are very big!”

As well as around €1 million in funding gathered collectively among its co-founders, key to developing ROC-E from a blank sheet was the use of ROS 2 and Nav2 by RobOcc’s engineers.

The former has been discussed extensively in this publication, and is today a widely used open-source middleware and SDK toolset for robotic and autonomous applications.

The latter is based on ROS 2 (while being another successor to the ROS navigation stack in its own right), with autonomy-centric aspects optimised for dealing with navigation challenges for ground and maritime surface robots. These include tools for perception, dynamic path planning, control, localisation and obstacle avoidance (as well as detailed behavioural trees) to facilitate customised, intelligent and reliable guidance through complex environments, together with execution of application tasks.

“And our team is one of the top contributors to Nav2’s open-source community worldwide, giving back as much as we can considering our unique ability to operate in environments beyond the industrial spaces familiar to AMR- and AGV-makers, while some qualities of our software do also remain closed,” Dehlinger says.

By June 2023, following six-to-seven months of rapid development, ROC-E’s first prototype was effectively completed. Productionisation followed similarly quickly thereafter: RobOcc applied for numerous patents covering its technologies in July, and the first commercial unit was signed for by RobOcc’s launch customer (Safran) in December later that year, with the system delivered, integrated and operational by the subsequent month.

“It took them two weeks to go through installation – a few hours for that, IT audits, cybersecurity audits and a week of operational tests – they’d never managed a robotic deployment with such speed before,” Dehlinger comments.

RobOcc attributes much of that peculiar pace to its engineers having targeted a few key challenges typically faced by AMR-type UGVs. One was keeping its design simple enough that it can be assembled as a kit, anywhere in the world. Additionally, making the system cyber-secure and assuring quality were both vital, as Dehlinger says. “If you are not building the robot yourself but just shipping a kit for the customer to put together, you need to be incredibly confident in the integrity of what you’re shipping.”

By keeping to a simple, kit-built design and also using COTS subsystems where possible (to avoid customisation expenses, and ease transparency and maintenance by avoiding unique, unfamiliar, undocumented products), RobOcc saved on manufacturing costs and hence working capital, enabling it to operate through to June 2024 when customer payments started flowing in.

“That in turn brought an issue of timing; robots like ROC-E typically take around five years to develop, not the half-year we took, but we couldn’t afford to wait five years to start making sales and revenue,” Dehlinger says. “That took a lot of our team’s ingenuity and health – but they remained motivated to show our previous employer that they were wrong to fire us, and they’ve demonstrated to me that I have some of the best engineers in the world in my team.”

Lastly, the company has also sought to make its robot and business operations as ecologically friendly as possible, both for the sake of the environment and for avoiding wastefulness in r&d and production (and some of the different ways they are achieving this are discussed henceforth).

Top to bottom SWaP

As mentioned, ROC-E consists broadly of four sections: a customised payload system on top, a comms system underneath, then some ROC-E-specific mission hardware components and the NOEME vehicular platform at the bottom.

NOEME is roughly 27 x 67 x 46 cm in size. Its subsections encompass a drivetrain system below, sensors for perception and localisation, computers for processing sensor data and a technical bay of around 3 x 50 x 38 cm, into which mission-specific electronics and interfacing equipment pertaining to ROC-E can be installed.

“If you compare the NOEME AIV against similar-looking, warehouse-type AMRs, you see NOEME is significantly smaller, lighter and therefore more agile; that’s how it can work in busy, unpredictable places like trade expo floors,” Dehlinger says.

“As well as aiming for minimal size and weight, we’ve also cut the integration costs as much as possible, which are so high that when you buy a conventional AMR, you actually pay around three times its price to cover integrating and deploying it into your business.”

Such costs often begin with hiring an integration consultant or manager, and building and installing mission-specific adapters or other equipment atop the vehicle. Then, it must be integrated into the organisation’s communication system, usually via wi-fi, which requires a highly reliable, homogenous wi-fi network covering an entire industrial area (a major technical challenge and investment, with no guarantee that a suitable network pre-exists the AMR acquisition).

“And another problem with AMRs conventionally depending on wi-fi, is that wi-fi isn’t built for persistent connections with moving vehicles – meaning such vehicles often experience frequent comms losses, false echoes and similar problems,” Dehlinger adds.

“Myriad other projects and costs follow, covering integration into the company’s IT system, the building of a fleet management system, getting a cloud server to host that, and so on. So, one of the key targets for ROC-E was building its autonomy, comms and cybersecurity to avoid almost all those integration problems, including keeping the base system very open so we can program the customer’s choice of interfacing protocols, OSs and other standards into their robot’s computer and network before delivery, saving them much of the work.

“That’s how we’ve opened up 95% of our present-day, previously untapped market customers for indoor autonomous robots, which are largely SMEs of 10-50 people who could never afford the conventional integration costs. ROC-E is cyber-secure and traceable by design, and most of our customers integrate it within one day, sometimes within an hour.”

The cargo handling module atop ROC-E is the one aspect of integration typically taken on by the customer, given that they will know best their practical needs. Hence, aside from rare occasions where the customer has asked RobOcc to handle this section or asked for the standard-issue shelf for carrying 60 x 40 x 40 cm crates, bespoke arrangements of shelves, plates, conveyors, elevators or grippers are typically commissioned by the customer from other suppliers.

“Some want more vertical arrangements than others, some want hybrid organiser modules with slots for both documents and raw materials, and some want slots for carrying tools for production machinery,” Dehlinger says.

“The mechanical parts of these modules often come from Usitech, with the electronics often coming from Occion, both located in Brens, 80 km from Toulouse. So, the customer typically deals directly with them.”

Switching from one payload module to another typically takes around 15 minutes, argely encompassing the removal (and then re-insertion) of fasteners and connectors from one module to the next. RobOcc notes that some customers will opt for one payload, such as a static, fixed shelf for eight months of the year, and then switch to an automated shelf carrier system for the other four months (owing to seasonal shortages of warehouse workers, for example).

Full metal ROC-E

The robot is largely built around a singular chassis formed from aluminium, with aluminium also used for the body plates that close the chassis and for internal mounting components.

“There is almost no plastic in the robot. Effectively, it’s fully aluminium, which is more recyclable and eco-friendlier than plastic, and the outer panels are removable to facilitate removal, replacement and therefore upgrading of internal subsystems by the customers themselves,” Dehlinger says.

“We’ve already had one customer receive hardware upgrade packages from us for their robot; those can consist of things like new, improved cameras because those advance all the time and can unlock improved reactivity and safety. Look at the few biggest names in AGVs and AMRs, and you’ll notice that nearly all of them use the Intel D435, which is a fine stereo camera, but was launched almost 10 years ago now. There’s so many new stereo cameras that have come out since then but they can’t upgrade to them.”

By contrast, ROC-E is built to enable easy access, unplugging and replacement of its sensors, motors and some other components; so long as the desired upgrade is specified, RobOcc implements a software upgrade with the necessary interfacing and driver updates to accommodate the new hardware.

Through this approach, RobOcc anticipates that customers will be able to acquire future versions of ROC-E not just by ordering whole new robots, but by requesting specific upgrade packages that will retrofit their real-time spec to the latest specs (the latter approach being less pricey and more eco-friendly than the former).

“As well as facilitating modular upgrades, the aluminium structure is even closed underneath with a 5 mm aluminium plate, which blocks against damage and penetration from a great deal of unwanted objects that can pass under ROC-E,” Dehlinger continues.

“We’ve worked with one customer that handled the pyrotechnic deployers for vehicle airbags; one key constraint there was that those devices could fall onto the floor and detonate under the robot as it rolls over.

“They’d broken some other robots exactly this way. But they saw ours, inspected the undercarriage and were satisfied by the 5 mm aluminium layer that it wouldn’t break. And there’s plenty of inanimate objects throughout factory, warehouse or hospital floors for instance that could pierce our lower electrical or electronic components if it weren’t for our structural approach.”

Power and movement

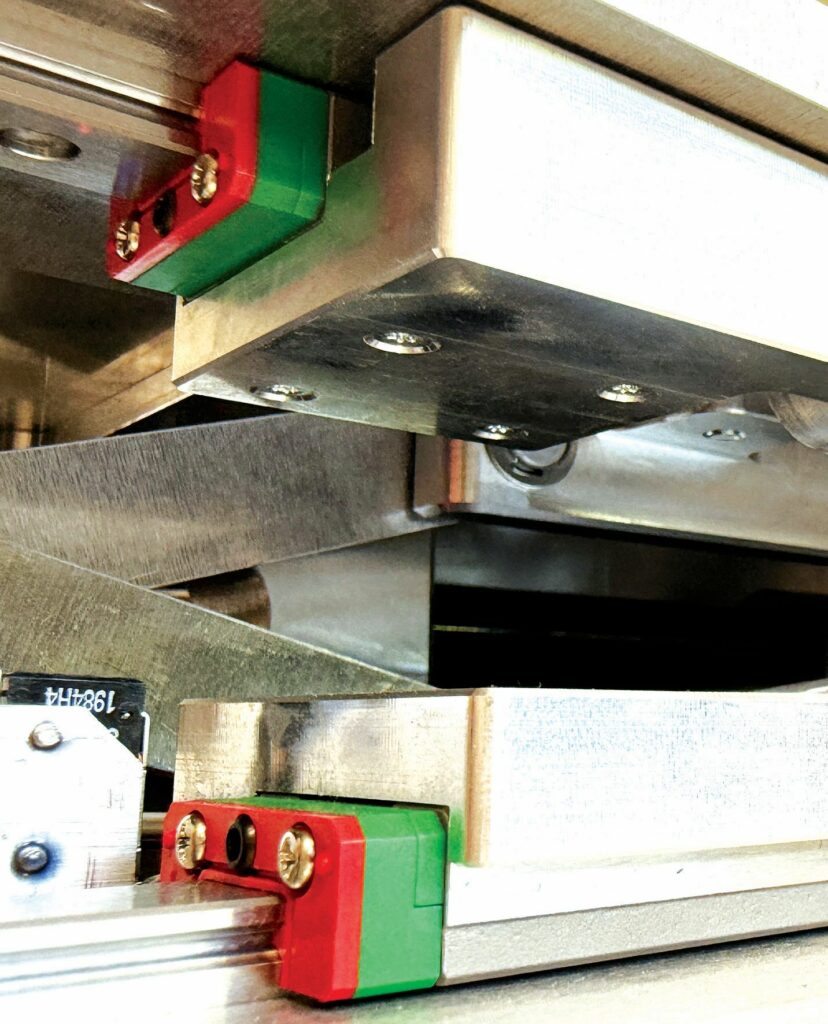

To maximise ROC-E’s functionality, the wheelbase on NOEME integrates two bidirectional, BLDC motors enabling equal forward and reverse traction capacity, two motor controllers, two traction wheels (one for each motor), two reduction gearboxes (one downstream from each motor) and four non-driven balancer wheels.

“We specifically avoided spin wheels – those wheels that can azimuth and turn in any direction, whether motored or otherwise – because we had experience with them from the past and had run into a lot of trouble,” Dehlinger notes.

“In industrial or logistics applications especially, debris like bits of plastic can be strewn across the ground; if there’s any space for them to get drawn up into the wheel, then they will. That can cause odometry errors by sticking the wheel, and such errors are a major reason why robots can get lost inside company facilities – the odometry is often a key input for positioning.”

Hence, the ROC-E (and NOEME) chassis wraps tightly around the fixed, motored wheels to prevent intrusion of foreign objects. To further safeguard the odometry (among other things), a unique, patent-pending balancing system has been engineered into RobOcc’s robot, which moves internal weight to maintain equal pressure on both traction wheels (both from the ground below and from the weight from above) so that odometry is accurate for both.

The motors meanwhile were chosen for their compact size and high power-to-volume ratio, being 60 mm in diameter and outputting 300 W, with which ROC-E is able to carry 100 kg of payload and with around 160 kg maximum loading.

Additionally, the powertrain has been designed and carefully balanced such that any collisions that might occur (should the autonomous collision avoidance system fail, occasioned for instance by someone stepping suddenly into a corridor and crossing paths with ROC-E) are tempered. Part of this comes from the robot’s very slow maximum speed; however, in a prolonged collision, ROC-E’s wheels will spin in place rather than drive against the contacted object or person.

“We worked a lot to find the right motor, with the right power – including a lot of simulation and hardware tests such that it drives with enough power to do the mission, but not enough to physically move a person or damage their shoes,” Dehlinger explains. “It gives you a gentle press at most, and then backs off to re-plan a safe and energy-efficient path.”

The battery provides 1 kWh of energy for the motors and electronics, and is another COTS product manufactured by TYVA Energie in southeast France. Usefully for RobOcc’s environmental-friendliness ambitions, the supplier will upgrade each battery pack or refurbish them down to replacing individual cells, rather than disposing of entire packs and modules when one cell hits end-of-life.

“And if a whole pack should reach end-of-life, TYVA has a full and normalised recycling process to re-use the whole thing,” Dehlinger adds.

That process involves TYVA working with Corepile (which has collected and recycled several tonnes of TYVA’s old battery cells since 2021). Pack housings are emptied and refilled with new cells, and the old cells are re-harvested for their internal materials, with their zinc, manganese and cobalt (to name a few examples) being reused for new industrial components, regardless of their remaining capacity for energy storage.

“Essentially, the only non-COTS component in the standard-issue ROC-E is the connector plate,” Dehlinger says. “That part is key to guiding connectors and ensuring the end-user cannot mis-connect any cable; it just won’t fit, not without breaking!”

Sensor architecture

The ROC-E sensor arrangement covers 360° horizontally and 150° vertically around the robot, ensuring that objects with no ground footprint (such as raised barriers, security tape or personnel holding an arm or tool outwards) are not driven into.

Significant engineering rigour has also gone into the sensor data fusion to achieve an indoor localisation precision with 5 cm maximum error. That error rate can shrink down to less than a millimetre for docking with charging stations if some aiding systems (such as the company’s own patented Lidar enhancement sticker system or an air plug) are integrated at the docking site.

“We have eight ultrasonics spaced equally around the robot. Then, we have two camera systems and one Lidar, plus an industrial-grade inertial system, and the electric motors also provide part of the data for odometry – the other half comes from the Lidar,” Dehlinger counts.

As demonstrated at the 2025 Paris Air Show, ROC-E’s embedded intelligence also allows it to recognise clusters of sporadically arranged objects (placing bounding boxes around them within an embedded 2D map it generates of its operating area, similar to the annotation boxes placed by machine vision systems when performing object classification) and distinguish them from walkways.

That aspect of its sensor fusion and intelligence enables it to stick to the walkways and avoid intruding through exhibitors’ pavilions. Hence, it will similarly tend to avoid sections of factories, hospitals and offices not meant to be walked through (strategically reducing the incidence of encountering people or workstations and, by extension, reducing reliance on its object detection and avoidance systems).

Each camera system is a multi-camera module (one pointing ‘forwards’ and the other ‘backwards’ – although NOEME is symmetrical without a distinct front or back) integrating a dual stereo camera for 3D depth sensing and wide detection, a 2D HD camera for longer range detections and an IR camera for continued intelligence in low visibility.

“An edge computer sits in the module as well for processing sensor data to save processing bandwidth and, similarly, we have dedicated microcontrollers for the Lidar and ultrasonics,” Dehlinger says. “The 2D cameras give about 120 m of reliable detection range, the Lidar gives about 60 m, and the ultrasonics work very quickly but just up to 10-20 cm.”

The main computer is an Intel NUC with a 14th generation i7 processor (containing 16 GB of RAM, a GPU and an SSD), running a secure, customised Linux OS. The sensors’ microcontrollers plug into this computer, as does a power management unit that functions as an intermediary to the two motor controllers.

“It’s a powerful computer, and running ROC-E does take 80% of the total CPU capacity; but each part of the robot has at least dual sourcing – some have triple sourcing – so we can replace this computer with another one if needed, and we have used a few different ones,” Dehlinger notes.

“In the meantime, we are dedicating some r&d to optimising our software stack, so as to use less of the CPU or switch to a smaller one; the big end objective being less energy consumption for day-to-day autonomy.”

Comms & security

A panel extending up from NOEME (designed roughly to be the same height as the end-user’s payload bay) displays remaining battery charge, enables mission planning and optionally integrates a USB3 plug for a wi-fi dongle and direct wired connection.

“Generally, we don’t want to use wi-fi, so we typically install a 400 MHz radio into ROC-E for those that need some kind of remote monitoring and in-the-loop controllability. But the panel is usually sized large enough that mission programming can be done directly on the robot and prevent entirely the need for a hackable remote connection,” Dehlinger says.

“All of this is optional based on customer needs, though; ROC-E can work with or without a display panel, with or without an RF connection or with dual wi-fi and 40 MHz connectivity. By and large, keeping it self-contained and radio-free is the best way to ensure its security; but naturally, some customers must have some kind of remote connection.”

The 400 MHz radio is built around a LoRa (Long-Range) modem and provides a slow, low-bandwidth connection into a dedicated mission computer (or application CPU) separate from the main computer. It is sufficient for transmitting simple, high-level commands to ROC-E, which the robot’s own intelligence can then break down into the low-level steps needed for execution.

“It’s around 1 kb/s, so it’s very slow, and doesn’t handle a lot of data – just enough to receive high-level commands like ‘come here’, and to periodically update its position and health for a fleet management system,” Dehlinger says.

“That’s a very deliberate choice for cybersecurity. Hostile agents cannot extract camera feeds, issue complex commands or push any significant malware into the robot because the bandwidth and level of access just aren’t there. By maximising ROC-E’s onboard intelligence and minimising the need for detailed teleoperations, we avoid having to extensively network the robot and give hackers an easy pathway into it.”

All electronics are sealed in a cryptographic case and communications are also encrypted, and remotely altering the robot’s program mid-mission requires entering security keys. WebSocket is the typical protocol used for comms, enabling interfacing and security to be programmed as needed using libraries in C++, C, HTML, Javascript and other languages.

“The robot architecture is also arranged such that remote commands cannot go directly into the subsystems – they first go via a secure microcontroller, preventing a direct bridge from the radio to the main CPU or application CPU,” Dehlinger explains.

“And the remote commands are not so much explicit orders but ‘indices’ or sets of orders that the radio’s microcontroller cannot unpack by itself. It’d receive something like ‘400’ from the radio, and then the main computer would understand whether that’s a battery settings change or waypoint coordinates to go to – whatever the end-user requires.

“So, it’s very hard for any hackers to know how to send any specific orders to the robot in the first place. They’d need to break into a customer’s factory, plug into the robot, hack the encryption and know the robot’s APIs to be able to modify something or understand the index library.”

RobOcc also develops and supplies its own fleet management software – principally for real-time supervision rather than micromanagement – as well as optional remote peripherals such as buttons or panels for triggering simple functions such as coming to the button’s location, or commencing an end-of-day duty such as emptying all of an office’s wastepaper bins.

“We can also supply peripheral triggers for installation throughout customer facilities that enable ROC-E to wirelessly interact with automatic doors, secure doors, elevators and so on, again secured outside of the important CPUs and subsystems,” Dehlinger adds.

“Those can also be installed on other machines or robots for them to autonomously call a ROC-E to collect something, like a finished product off an automated line, without an IT connection. No modifications on ROC-E are needed for any of that; its autonomy stack already accounts for such behaviours. So, making the robot as intelligent as possible has really helped keep things simple from a supply point of view.”

Going forwards

There was a time, in the course of its r&d that RobOcc considered developing humanoid robots rather than the wheeled system at the heart of its business today. However, in addition to the greater engineering challenge this poses, an even more severe problem of acceptance stayed the company’s hand: Dehlinger and his team anticipate it will be some time before people cease to find humanoid robots unnerving and reach the point that they will happily work alongside them.

For now, RobOcc plans to continue steady production of its ROC-E AIVs for its customers, as well as r&d into worthwhile upgrades.

Key specifications

ROC-E

Intralogistics UGV

Fully autonomous

Battery-electric

Dimensions: 90 x 67 x 46 cm

Empty weight: 60 kg

Maximum payload weight: 100 kg

Maximum speed: 0.8 m/s

Maximum endurance: 10 hours

Standard charging time: 2 hours

Onboard energy storage: 1 kWh

Maximum detection range: 120 m

Some key suppliers

Main computer: Intel

Lidars: Pepperl+Fuchs

Battery: TYVA Energie

Customised payload modules: Usitech

Payload electronics: Occion

UPCOMING EVENTS