Ocean Business 2025

Easy autonomy

Peter Donaldson navigates his way to Southampton and discovers the offerings at Ocean Business 2025

Held from April 8 to 10 at the National Oceanography Centre in Southampton on England’s south coast, Ocean Business 2025 was a rich source of information on new and improved sensing, navigation and communication systems for USV, UUV and UAV systems, with a focus on ease of use and autonomy support.

Airmar/MSI Transducers is responding to the demand for increasingly compact, low-power and high-resolution sonar systems with its new generation of single-beam transducers – specifically the B200 and its very low-sidelobe variant, the B200 LSL – which it introduced at the show. These transducers are designed to improve acoustic performance in shallow water and near-platform environments where multipath interference can be a challenge.

In addition to the new single-beam transducer, split-beam transducers such as the SB200 divide the transducer face into four quadrants, allowing not only precise beam transmission but also directional reception and thereby enabling three-dimensional localisation of echo returns. “By getting the different angles in on different quadrants, you can estimate the position of an object and compensate for objects near the edges of the beam to form a better image than from just a single solid beam. This is especially useful in determining the species and size of fish,” explains Ryan Pellecchia at Airmar/MSI.

The B200 LSL advances this functionality by incorporating very low-sidelobe characteristics, significantly reducing off-axis interference. “You’re really just looking at the main beam. That’s what everybody really cares about,” Pellecchia adds. This makes post-processing more efficient, allowing software to filter out noise more easily and extract clean data from the main acoustic return.

The transducers are designed to operate over a wide range of frequencies and are optimised through acoustic engineering – including piezoelectric ceramics, backing layers and matching layers – customised to operational depth. Airmar/MSI supports deepwater applications down to 6000 m, using pressure-tolerant ceramics and robust packaging.

Advanced Navigation outlined the capabilities of its Subsonus ultra-short-baseline (USBL) system that combines acoustic positioning, inertial navigation, and communication in a single, compact form factor. Described as the keystone of a subsurface positioning and communication ecosystem, Subsonus provides reliable tracking through advanced signal processing and unique hydrophone design, and accepts inputs from external sources, according to Chris Sundstrom.

“Our systems are more than just base level units, and they’re not intended to be operated as closed systems,” Sundstrom says. “Subsonus is not just a USBL – it’s got the inertial navigation system (INS) built in, and it can take in the navigation solution from a Doppler velocity log (DVL), GNSS receiver or even more advanced INS sources.” Operating as deep as 1000 m, the system accepts data via Ethernet or serial interfaces, allowing seamless integration with other sensors to deliver geo-referenced positioning. The system also operates as an acoustic modem for low-bandwidth text-based communication.

Subsonus also supports Advanced Navigation’s ‘USBL²’ mode, enabling beamforming on both ends of the acoustic link. When paired with a second Subsonus on an underwater vehicle, this dual-transceiver setup yields non-magnetic acoustic heading and enhanced positional accuracy – critical for operations involving small, metal-sensitive platforms.

Subsonus’ advanced hydrophone array – eight elements in two offset planes – enables precision beamforming and can even determine local sound velocity, eliminating the need for a separate sound velocity sensor.

Its extended ecosystem includes the Tag beacon, connector-less transponder that features an electronic paper display readable by divers, and supports inductive (Qi) charging and both Bluetooth and wi-fi short range communication.

ANB Sensors is advancing water monitoring capabilities for UUVs with a new generation of calibration-free pH sensors, designed specifically for harsh subsea environments. Speaking at a recent event, James Hill at ANB Sensors explained the limitations of traditional glass electrode-based pH sensors, which require frequent calibration and are prone to drift, creating uncertainty in measurements. “It’s very difficult and expensive to recalibrate these pH sensors subsea,” Hill said. “You don’t actually know if the pH is changing or if it’s electrode drift.”

ANB’s solid-state sensor technology eliminates the need for recalibration. Their rugged titanium-bodied OC series uses a novel multi-electrode reference system to validate readings continuously. “If one reference electrode is down, it will check the others; hence, why we can detect actual drift versus a real pH change,” Hill noted. Maintenance is simplified to occasional light abrasion of the sensor head, extending operational life to up to a year depending on measurement frequency.

The detection principle relies on changes in conductivity across a specially designed carbon-based transducer. “It’s as accurate as any glass electrode out there,” Hill said, adding that units are validated against traditional sensors before deployment.

ANB’s pH sensors are already being integrated into ROVs, AUVs, sondes and fixed monitoring installations. Remote health monitoring and industry-standard interfaces (RS-232, RS-485, Modbus) make integration straightforward. “Because of the ruggedised design, it suits remote and difficult-to-access environments,” Hill added.

Although initial industry response was cautious, Hill reported that successful trials have built momentum. “Now we’ve got real traction going forward,” he said, highlighting expanding use in oceanography, oil and gas, aquaculture, mining and environmental monitoring sectors.

Exail showed the Octans 9, which is the latest evolution of its Octans series of attitude and heading reference systems (AHRSs). Designed for crewed and uncrewed surface vessels with dynamic positioning systems, the Octans 9 boasts enhanced performance over the proven Octans 5 of which it is a development, and is also free of export restrictions and US Department of Defense arms trade regulations. Exail’s Jean-Michel Hubert, speaking to us at the show, explains that this is possible because both the core sensor and the system level technology are developed in house, with no reliance on US controlled components.

Octans 9 is based on fibre-optic gyro technology, which has no moving parts, and offers a 25% reduction in size, together with lower power consumption compared with Octans 5, achieved through redesigned internal electronics architecture.

One key advantage is Octans 9’s ability to align ‘on the move’ using GNSS. Hubert explains that, with previous products, vessels would have to be stationary or moving at very low speed, “but now you’ve got no limitation in terms of movement when aligning the AHRS.” Once aligned, the Octans 9 can maintain accurate heading, roll, and pitch for extended periods, even during GNSS outages, he says, achieving attitude accuracy of 0.1 second latitude RMS.

Furthermore, increased CPU power enables advanced algorithms for GNSS processing and heave management, crucial for platform stabilisation in offshore operations and similar applications.

(Image courtesy of Exail)

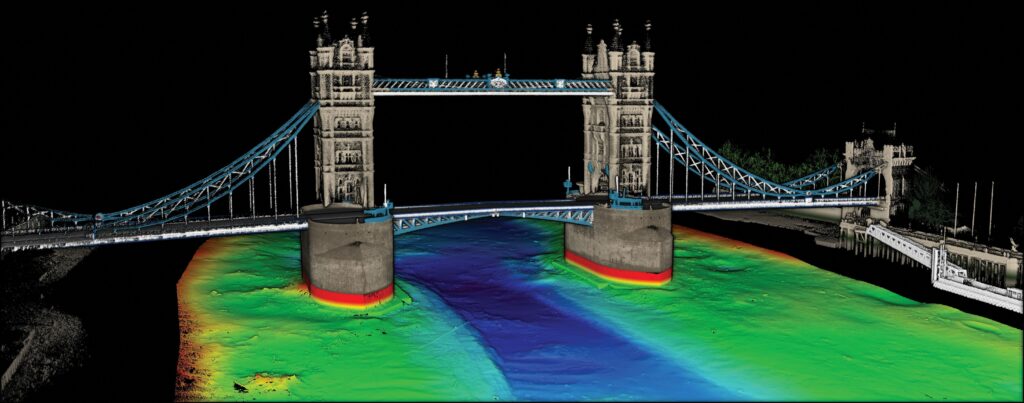

Norbit Subsea discussed its latest generation of multi-beam sonar systems for USVs and UUVs. These sonars are built around frequency modulated (FM) chirp technology, and are designed to provide a combination of high-fidelity bathymetry data and ease of use, minimising the training burden for operators.

“What makes our system really applicable to those platforms is tight integration, low power draw, and the ability to access the data remotely via low bandwidth links directly on a web browser,” explains Mike Mutschler from Norbit.

Designed for both USVs and UUVs, Norbit’s FM systems transmit long pulses across wide bandwidths, enabling stronger returns and higher signal-to-noise ratios. This means more precise, wider swath coverage – ideal for both structure mapping and bathymetry missions.

On uncrewed surface vessels, real-time operator control is facilitated through a browser-based interface, enabling high-resolution 3D point cloud and bathymetric map visualisation on any device such as a computer, tablet or smartphone. “There are no drivers, no geodetic parameters to set up; it works automatically,” says Mutschler. The system integrates Trimble RTX positioning for centimetre-level accuracy and simplifies bathymetric data collection to the point where “somebody with maybe a day of training” can produce survey-grade results.

For subsurface platforms, Norbit’s compact design and internal signal processing mean that it is well suited to vehicles with tight space and power constraints. “All the data processing happens inside the sonar head itself,” Mutschler notes, which means that only a simple network cable is needed – no bulky topside units or high-bandwidth links.

The systems are currently being integrated on a wide variety of platforms including Bedrock’s AUV family and Saildrone’s USVs.

Riegl continues to push the envelope in Lidar technology for UASs. Speaking at Ocean Business, Riegl UK’s Dave Foster highlighted the company’s expanding portfolio of Lidar systems tailored for UAV deployment, including both topographic and bathymetric models capable of high-resolution data capture across diverse environments.

Riegl’s 1.55 kg MiniVUX-3UAV represents the company’s entry-level topographic Lidar system for UAVs, offering robust performance in a lightweight form factor. For bathymetric applications, RIEGL’s 12 kg VQ-840-G and 15 kg VQ-860-G units deliver green laser penetration of the water column, making them ideal for shallow marine and inland waterway mapping. The flagship VQ-860-G system can be carried by larger UAVs and employs full-waveform, time-of-flight technology and exceeds 2.5 Secchi depths, translating to potential penetration of 10–20 m in clear water.

“The 860G puts us at the cutting edge of the technology,” Foster notes. “We’ve engineered it for maximum performance, particularly in coastal and riverine applications where sonar may be less effective.”

The VQ-840-GL is UAV-optimised, with the GE variant weighing under 10 kg, suiting it to integration on heavy-lift drones in the 25 kg class. While lighter, the GE entails some trade-offs in capability compared with the GL model. Foster emphasises that such trade-offs are part of the ongoing balancing act in Lidar engineering: “Everything’s a compromise – smaller and lighter usually means giving up something, but we’re constantly improving performance across the board.”

Riegl’s systems are built for rugged, professional use, with recommended service intervals of two years, and integrated features like air cooling, environmental tolerance (0 to +40 °C) and software-enabled waveform analysis.

RTSys presented its NemoSens and Comet 300 autonomous underwater vehicles. These vehicles are designed to address a growing need for versatile and easily deployable multi-sensor subsurface survey platforms.

The NemoSense is a micro-AUV, weighing 10-12 kg, designed for one-person handling. The Comet 300 is its larger counterpart, measuring 2 m in length and weighing around 40 kg, but still easily manageable by a two-person team. Both AUVs can be used for similar missions, including seabed mapping with side-scan sonars, object detection and magnetometer capability for locating buried objects. They can also carry video cameras and multi-parameter probes for scientific data acquisition. The primary difference lies in the available on-board power, with the Comet 300 offering more power for speed, payload capacity and accuracy. Both vehicles are depth-rated to 300 m.

A key recent enhancement is the integration of a fibre-optic gyro-based INS on the Comet 300. According to Corentin Troussard at RTSYS, this enhancement significantly boosts navigation accuracy, meeting the demands of customers for greater positioning accuracy in their survey data.

RTSys discussed its system of surface buoys that can be deployed to act both as communications relays for basic commands and telemetry, and as positioning systems. “The latter uses triangulation, both to track the vehicle under the water and relay its position to operators on the surface, and to correct the vehicle’s own navigation solutions,” Troussard explains.

Troussard notes a significant shift in industry perception, with very small AUVs increasingly recognised as essential tools and no longer dismissed as mere gadgets – as was common as little as five years ago.

SBG Systems announced the launch of what it claims is the world’s first gyro compass based on micro-electro-mechanical systems (MEMS) sensors, which is significantly less expensive than gyro compasses based on fibre-optic gyro (FOG) technology. Like other modern gyro compasses, the sensor can find true North without external reference, such as GNSS, and is immune to the influence of metal structures that disturb magnetic compasses.

“At the heart of the technology are tiny plates that vibrate at high frequency,” says SBG Systems’ Mathieu Peyrega. “It works because these plates are sensitive to the Coriolis effect, which induces torque,” he explains. “It’s like when you’re driving and you brake or turn, you feel the inertia.” The resulting pattern change is converted into electric current, from which the rotational rate and orientation are calculated.

The core innovation lies in SBG’s ability to overcome the inherent limitations of MEMS inertial sensors, which offer size, power and cost advantages over FOGs but have historically lacked the precision required for accurate seeking of true North and minimising drift. Peyrega underlines that SBG’s “special sauce” is the calibration. Each device undergoes very controlled, extensive tests across a full range of speed, acceleration and temperature. “The result is an individual correction curve, which is then embedded into the software and coaxes the technology into achievements that wouldn’t otherwise be possible.”

The gyrocompass boasts a one-degree per second attitude accuracy, needing just 1 minute to initialise and 5-6 minutes of convergence time to achieve its final specified accuracy.

(Image courtesy of SBG Systems)

SubCTech discussed its new 1 MWh underwater lithium-ion battery system, now in production in Norway, designed to meet the rising energy demands of resident UUVs and seabed infrastructure. Built on the company’s established SmartPowerBlock architecture, the modular system is housed in pressure-tolerant, depth-rated enclosures capable of operating at 6000 m.

Scalable and skid-mounted, the new battery system consists of 12 stackable battery housings. Each module is equipped with a local battery management system (BMS) and overseen by a master BMS for coordinated control. “In case of a failure, you can disconnect part of the battery without shutting down the whole system,” as Sören Johannsen from SubCTech explained to us .

SubCTech’s use of high-energy-density lithium-ion chemistries, supported by full Mil-Std, UN38.3 and TNV certification, enables both air-transport logistics and long-duration deployments. While cylindrical cells remain standard, variations in cell chemistry are tailored to client voltage and energy density requirements.

One of the most compelling applications is its integration into renewable-powered subsea ecosystems. “Right now, we’re working on recharging AUVs on the seabed without surfacing. The next step will be to recharge the docking stations with wind, wave or solar energy,” says Johannsen.

With system envelopes maintained at 460 mm diameter and 2.4 m length per unit, “compatibility with existing launch and recovery systems is preserved, even as total energy capacity has scaled sixfold over the last decade,” he notes.

Teledyne Marine launched the Compact Navigator – a fully integrated inertial navigation solution – developed to meet the growing demands of small uncrewed subsea and surface vehicle applications. Developed through a multi-year collaboration between Teledyne’s RESON and RDI teams, the system merges multiple precision sensors into a single, compact unit with survey-grade performance.

At the core of the Compact Navigator is a tightly integrated suite of sensors: a fibre-optic gyro-based INS, a custom 600 kHz phased-array Doppler velocity log (DVL), a 0.01% full-scale pressure sensor and a temperature sensor.

“We are agnostic to inertial technology, although this has a fibre-optic gyro inside,” says Rolf Christensen at Teledyne Marine. “But we are really looking at all of the technologies out there, including MEMS, ring laser gyros and hemispherical resonator gyros.”

The phased-array DVL design enables a flush-mounted, hydrodynamically efficient profile that is ideal for AUVs and surface vessels. It provides up to 150 m of bottom track range, with a 300 kHz version offering up to 450 m – essential for deepwater AUV operations and applications in littoral waters. An integrated fifth beam for direct altitude measurement will be enabled in a future software release.

The unit is fully autonomous and delivered with a factory calibration of all sensors, thereby eliminating field alignment and minimising setup time. “You take this one, fit it onto the vehicle, put in a cable, power it up, and it’s navigating,” Christensen notes.

Compact Navigator’s modular design supports both 300 m and 4000 m depth-rated versions, with a custom subsea connector preserving the system’s 114 mm diameter.

Trimble Applanix discussed recent updates to its GNSS-aided INS ecosystem, with a spotlight shone on the latest release of its POSPac Mobile Mapping Suite (MMS) software. Version 9.4, unveiled just ahead of the Ocean Business event, introduced both technical enhancements and a significant shift in how customers access and deploy the package.

A key advancement in version 9.4 is POSPac MMS Complete, which is a new all-in-one addition to its subscription-based licensing model. With this new bundle, users can now access the full suite of features and processing modes, including PP-RTX on a more cost-effective annual basis. “It allows more people to enter the post-processing world without that initial capital outlay,” explains Nick Smart at Trimble Applanix. “The subscription model ensures customers receive the latest updates, features and support over the term of their license.”

In parallel with the new bundle, the introduction of POSPac Assure offers users a low-cost, low-barrier tool for quality control of their real-time data. Users can upload and analyse real-time navigation data, verifying installation parameters and ensuring data integrity before mission-critical deployment.

According to Smart, POSPac Assure “gives you that assurance that you set the vessel up correctly,” helping teams validate configurations with minimal technical overhead.

(Image courtesy of Trimble Applanix)

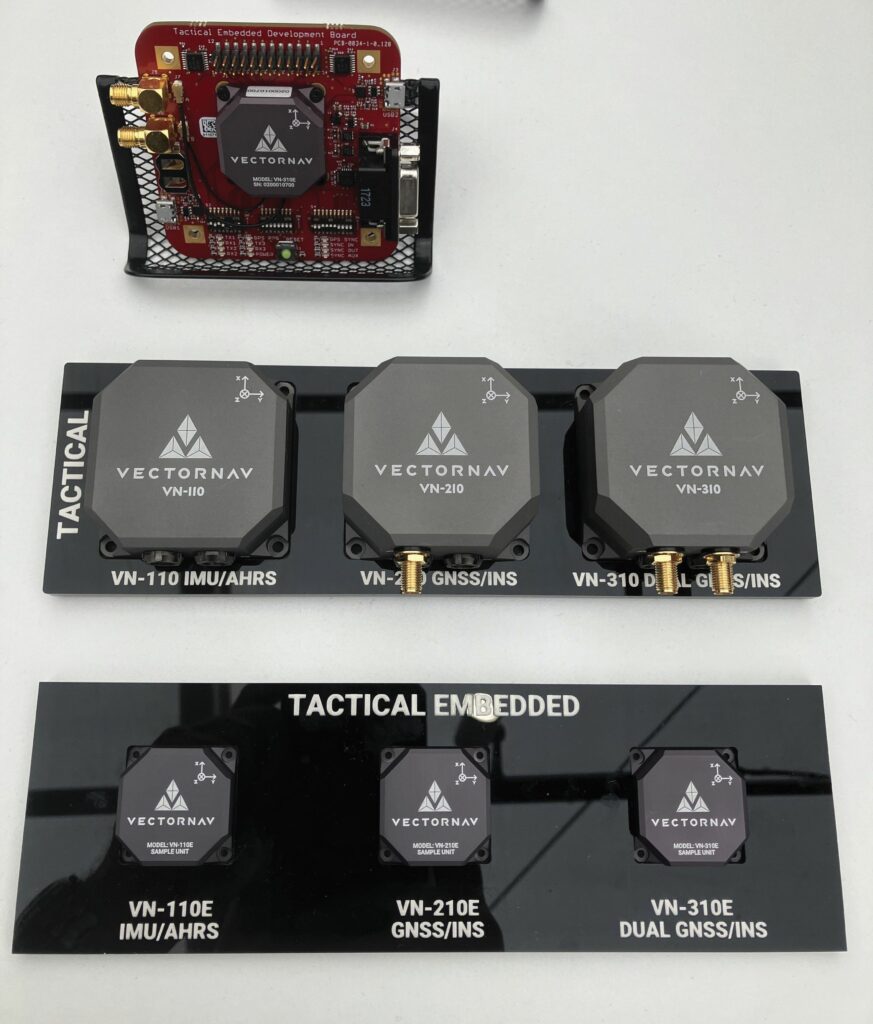

VectorNav Technologies showed its industrial and tactical series of inertial measurement units and GNSS-aided INSs, designed to provide assured position, navigation and timing for pointing and stabilisation across uncrewed platforms. The systems on show included VectorNav’s industrial series, including the VN-100, VN-200 and VN-300, and the tactical series comprising the VN-110, VN-210 and VN-310, both available in ruggedised packaging and with chips designed for embedding in customers’ systems. “We are showing the smallest INS/GNSS on the market at this performance level,” says David Friesen at VectorNav. The systems are targeted at a variety of applications, including uncrewed surface and aerial vehicles.

VectorNav’s systems feature temperature-calibrated gyroscopes, accelerometers, magnetometers and integrated GNSS receivers – single or dual antenna – delivering heading and position outputs. “We build many redundancies into our products to maintain precision, even in challenging environments,” Friesen explains, noting that they provide fallback options when magnetometer or GNSS signals degrade. Their tactical series of sensors is compatible with several external PNT sources and external IMUs, offering enhanced capabilities for GNSS-challenged or -denied environments.

The systems are multi-constellation capable, supporting GPS, GLONASS, Galileo and BeiDou systems, with tactical models offering L1, L2 and L5 bands for enhanced robustness. Customers can also select different GNSS receivers within the tactical series VN-210 model; a newer offering aimed at enhancing resilience against jamming and supporting capabilities such as hypersonic systems.

Friesen emphasises the established global footprint of their products, with sales in over 65 countries. The sensors have evolved to serve a wide range of air, land and maritime applications, delivering critical navigation solutions where pointing, tracking and stabilisation are mission-essential factors.

Voyis unveiled the latest integration of its Discovery stereo camera system on the SAAB SeaEye Falcon ROV, highlighting better optics and real-time modelling capabilities that enhance the creation of 3D images underwater. The integration, completed in collaboration with fellow Covelya Group companies Sonardyne and EIVA, leverages Voyis’ expertise in optics and EIVA’s proficiency in visual simultaneous localisation and mapping (V-SLAM) software.

Patricia Sestari of Voyis emphasises the system’s growing reliability, noting that the Discovery has now received Bureau Veritas accuracy certification. “If you’re doing subsea inspections, you can be sure of the measurements you’re taking,” Sestari says.

One of the key upgrades includes a redesigned lens aimed at improving image clarity across the entire frame. “We noticed that we could make photogrammetry more efficient if the images were clearer in all the corners,” Sestari explained. “With more tie points in the images, you’re able to create more reliable 3D models.”

Making such improvements to wide angle lenses for underwater use generally involves correcting optical aberrations that result from curvature of the focal plane, distortions to off-axis points, and chromatic aberrations caused by different wavelengths focusing at different points. Uniformity of illumination and the refractive behaviour of water must also be addressed.

Integrated with Voyis V-SLAM powered by EIVA’s NaviSuite, the camera now enables real-time 3D modelling and spatial awareness. Operators can immediately identify any gaps in data coverage, thereby streamlining missions and enhancing quality control. “It allows you to do data quality control as it’s generating the 3D model in real time,” Sestari notes.

The system was trialled recently in the UK, where initial tests delivered “very impressive results,” claims Sestari.

Water Linked AS displayed its Sonar 3D-15 imaging sonar in a transparent water-filled cylindrical tank on its stand. In the centre of the tank was a set of solid 3D symbols, high-resolution images of which were shown on a screen with the viewed aspect changing in real time as the transducer head moved around the circumference of the tank. The idea was to showcase the sonar’s image quality and demonstrate that its speed of response is sufficient to support obstacle avoidance algorithms. The system is designed for both underwater navigation and intricate inspection tasks in poor visibility, according to Scott McLay from Water Linked.

The sonar operates at central frequencies of 1.2 and 2.4 MHz. The first is optimised for navigation and obstacle avoidance, providing a broader field-of-view and longer detection range, while the second provides the resolution needed for detailed inspection of structures. “Being able to see things in 3D is far more intuitive than using 2D imaging sonars,” McLay says.

While modern USBL acoustic positioning systems, coupled with GNSS/INS support, are increasingly accurate, a lack of real-time, forward-looking situational awareness has hampered autonomous navigation, he notes. The Sonar 3D 15 offers this crucial capability. “Every image you see has approximately 16,000 data points that are all geo-referenced relative to the actual position of the sonar.”

Coupled with the rapid update rate of real-time processing, this high resolution paves the way for more sophisticated autonomous behaviours, including dynamic obstacle avoidance, autonomous target identification and the creation of 3D environmental maps for change detection and future mission planning.

(Image courtesy of Water Linked)

UPCOMING EVENTS