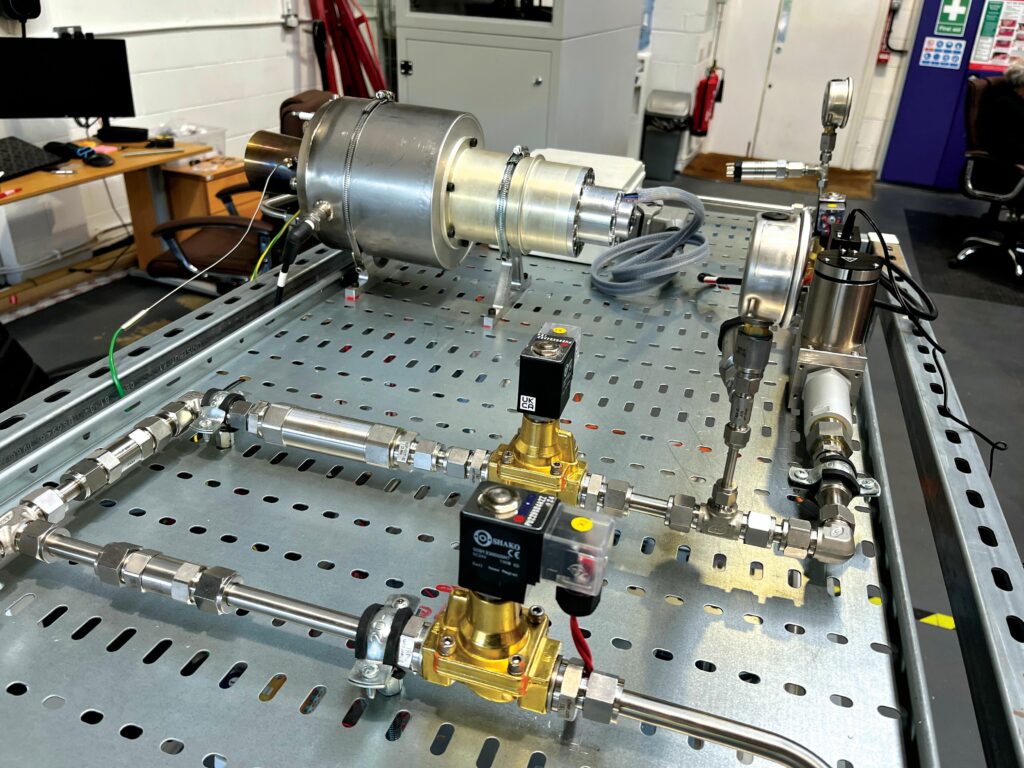

NEX Power 15 kW GenSet gas micro-generator

(All images courtesy of NEX Power Ltd.)

Turn up the heat

Rory Jackson investigates a novel micro-turbogenerator design, aimed at reducing microturbine development and build costs to competitive levels for hybrid-power UAVs, electromobility, and combined heat and power

Located in the UK industrial powerhouse of Milton Keynes, NEX Power Ltd., formerly known as Samad Power, is a developer of gas microturbine-based technologies. The company had its genesis at Cranfield University (the birthplace of many other uncrewed systems and related innovators throughout Britain), where the NEX Power CEO Seyed Mohseni started a journey that has secured over £5m in funding for its r&d so far – although it began in a somewhat different place to that, which we typically focus on.

“Changing our name to NEX Power came with a change of business strategy, although the core technology is still continuing the r&d from my doctorate from Cranfield; the subject being how to achieve both low-cost development and manufacturing of gas microturbines, for power generation as well as combined heat and power [CHP] applications,” Mohseni explains.

The main character of Mohseni’s PhD thesis was a 3 kW microturbine designed to produce power by running on natural gas. Its exhaust gases would be run via a heat exchanger, which would then enable heating for a building, whether for water or space heating.

The approach was one of several competing micro-CHP solutions, supported by the UK Department of Energy and Climate Change’s Feed-in Tariff scheme for boosting small-scale renewable energy tech uptake.

“One problem with using that 3 kW CHP boiler microturbine was that, compared with a normal gas boiler, it would likely be three to five times more expensive, principally because you’re applying jet propulsion to the low-cost gas boiler industry. The Feed-in Tariff was a great help for commercialising our technology in that regard, but around 2015-2016, the scheme was stopped suddenly,” Mohseni recounts.

He and his team had, however, achieved several successful r&d programs and partnerships, including one novel case of solar-thermal generation in which a concentrated solar power parabolic dish system focused the sun’s radiation on a thermochemical energy storage unit, heating it to 1200 C to drive a gas microturbine and its generator, potentially for combined power, heating and cooling (viewable at https://www.youtube.com/watch?v=p10FHSgCTEs). The partner in question has gone on to build further prototypes in South Africa using NEX Power’s solutions.

“So, we kept going and looked for applicable markets for our technology. CHP is a highly cost-driven industry and microturbines aren’t cheap,” Mohseni says. “Microturbines are very, very reliable, and the power-to-weight ratio is also very good, but compared with, say, reciprocating engines or normal, household gas generators, their prices are high.”

To make the company’s microturbine more price-competitive, the design was scaled up to a 15 kW unit, and simultaneously a few main areas were identified as suitable for applying its technology, each defined by its own approximate price point at which the market would accept the engine – with each price being ‘unlocked’ at a certain scale of unit manufacturing.

“We can’t go straight to stationary power because a 15 kW CHP system has to cost $3000, and we’d need to manufacture 50,000 units per year to get the price that low. But aviation demand is driven less by initial price and more by power-to-weight ratio, and manufacturing just one thousand 15 kW turbogenerators per year would enable a price of $15,000 per unit, which is competitive for aerospace, particularly range extension in high-end UAVs,” Mohseni says.

“For instance, a multirotor or VTOL-transitioning UAV running on 15 kW of power for two hours, or 30 kWh, would probably weigh around 75 kg if designed well; but 30 kWh of batteries weighs at least 150 kg, making it impossible for such UAVs to go all-electric.

“On the other hand, our 15 kWh gas microturbine, plus fuel weight for two hours and all other ancillaries and mounting components, comes to 40 kg. Certainly, as flight endurances drop, electric becomes much more competitive, but UAV missions aren’t getting shorter; they’re getting longer. So, our 15 kW GenSet is well-positioned as a UAV range extender, and also as an auxiliary power unit (APU) for air taxis because 15 kW of auxiliary power has historically suited 10-passenger private jet designs.”

NEX Power’s 15 kW GenSet is 450 mm long, 180 mm at maximum diameter and has a dry weight of 10 kg. The turbogenerator outputs power over an 800 V DC bus (850 V maximum) with up to 55 ARMS as its nominal phase current, the typical configuration featuring an alternator at the front together with the air intake and filter.

As of the time of writing, the 15 kW GenSet is considered by Mohseni and his team to be at technology readiness level 8, with level 9 consisting of final designs for integration and manufacturability per a given end-user’s specifications, as well as some final stages of work on its ECU.

Turbo development

As Mohseni explored in his PhD, the costs associated with both developing and manufacturing microturbines are a major reason why such units are not used more widely in UAVs.

“Capstone Turbine [now Capstone Green Energy], for instance, invested hundreds of millions to develop their stationary power microturbines and, respectfully, they’re now struggling financially because of how much they need to recoup, which drives up their product prices, and that makes it harder to scale-up production to bring that price down to market levels,” he says.

“But going into UAVs first, with a technical strategy of modularising our microturbine design, enables us to optimise for different use-cases with much lower non-recurring engineering costs.”

In pursuing other means of reducing development costs, Mohseni and his colleagues also looked into COTS solutions such as automotive turbochargers for inspiration, given analogous architectural features such as their very small compressors, turbines and high-speed shafts.

That led to the 3 kW microturbine design featuring a turbine with a screw, a very different compressor design with a screw, and an alternator mounted between the two that acted as both starter and generator for the system.

“I later found out that other companies used similar architectures, including Ferrari in their Formula One engines of the time, and Garrett in one of their hybrid-electric turbocharger designs,” Mohseni recounts.

However, the design had a couple of problems revealed through lifetime testing. For one, its shaft ran in an oil-lubricated bearing and, over time, the oil would leak through to the hot side of the engine. The heat would cook the oil and that would gradually impair the turbine’s rotor dynamics, reducing its lifespan significantly.

“For Formula One turbochargers, that’s fine – they don’t need much runtime – but micro-CHP units need a mean runtime of 20,000 hours between failures. So, we switched to an air bearing technology, also called foil bearings, to get rid of the oil,” Mohseni says.

Additionally, as lifetime testing also revealed that the alternator’s magnets would become demagnetised owing to the heat of the turbine, the alternator was moved to the front of the engine (in front of the cool compressor section) as part of the overall redesign.

That redesign came in useful when the microturbine design was being conceived and rescaled for applicability in the UAV space, with the air bearing technology and frontal alternator configuration both being incorporated into what became the 15 kW GenSet.

As Dr Esmail Najafi, director and product lead at NEX Power recounts to us, “Such technologies were not invented, but customised and scaled-up for this engine, with the concept of the 15 kW turbogenerator coming around 2019.

“As well as the good commercial fit being a general motivator, demand for a power unit of this size came from our sister company ARC Aero Systems, which develops crewed and uncrewed aircraft – and it took about five years of engineering, with prototype tests starting in mid-2024.”

Several prototype iterations were created over the course of NEX’s development (each round of modifications coming as a response to bench tests running to a failure of some sort). Two units of the present-day version are built and running on test benches to validate and characterise their capabilities, with an estimated 250 hours of test data recorded on those units at the time of writing.

“On the previous iteration, we’d exceeded 500 hours of testing before deciding to modify it further; of the two modern units built, one drives its alternator via a coupling, and the other is direct-drive – the latter being the approach we’re taking commercially,” Najafi adds.

“We’ve also tested the engine on hydrogen, including static tests on one of ARC’s cargo UAVs; we integrated the 15 kW turbogenerator and a bottle of hydrogen and it ran smoothly.”

Operating principles

The 15 kW GenSet differs notably from the other gas microturbines we have featured in this publication – specifically, UAV Turbines’ (Issue 14), Turbotech’s (Issue 31) and Aant Farm’s (Issue 51) – in that those microturbines all integrated some form of exhaust heat recuperator.

They did so because microturbines exhibit significant fuel inefficiency relative to reciprocating engines as their power outputs drop past 2000 hp, and their thermal inefficiency becomes pronounced at power levels below 300 hp. Recuperating exhaust heat and using it to preheat intake air reduces the fuel quantity needed to achieve target power outputs; hence, boosting fuel efficiency to levels desirable to fleet operators.

Mohseni does not dispute this. “Below 30 kW, you get around 10-11% thermal efficiency – that’s compared with around 20% for a similarly scaled piston engine. The advantage of the microturbine compared with the piston engine is lower weight, and if you look at the overall mission, having a lighter engine that consumes more fuel and makes the aircraft lighter over time becomes more advantageous than a heavier engine consuming less fuel, in certain aspects.”

Furthermore, NEX Power has accumulated copious experience in building and integrating heat recuperators onto its microturbines, per the company’s CHP days. However, it has also found that heat recuperators are expensive, heavy and challenging to operate. For example, when a microturbine with a heat recuperator turns off, its electric motor must keep running so as to pull cooling air through the engine, owing to the recuperator forming a giant slug of super-hot metal around the combustor and exhaust ports.

“If you don’t put a load of extra time and energy into cooling that recuperator completely, the heat will spread through to the electric motor and destroy it,” Mohseni explains.

“So, for customers that really need long range, we can customise and install a recuperator suited exactly to their platform, especially with advances in additive manufacturing making it easy to reduce the weight of a recuperator, and optimise its thermal and mechanical pathways.

“But it’s important that customers understand just how severely adding a recuperator will change their UAV’s mission envelope and price.”

Hence, the GenSet’s standard issue 15 kW design does not feature a heat recuperator; instead, the system is a simple cycle gas turbine with four main sections, and all active parts run on a single shaft, with (technically) no power turbine because, semantically, a power turbine drives a propeller. Starting at the front, air is pulled in through an air filter and an alternator by a compressor, enabling cooling for the alternator – a critical requirement given the lack of a propeller and potentially of any forward motion to otherwise forcibly air-cool the alternator – as well as providing compressed air for the combustor.

That compressed air flows into the combustor chamber, where fuel is injected for mixing with the air, and conventional igniters provide ignition for gasoline. If heavy fuels, diesels or other compression ignition fuels are used, ignition aiding in the form of glow plugs are integrated and used. The ignited charge then runs into and drives the turbine that, as indicated, links to the compressor and alternator via the common shaft.

“The alternator serves as both starter and generator, initially motoring the compressor to about 40,000 rpm, at which point there’s enough compressed air for the combustor to ‘turn on’ with the incoming fuel, and thus enough power coming from the combustor for the turbine to start helping rotate the shaft,” Mohseni explains.

Najafi continues, “So, below 40,000 rpm, 100% of rotation is provided by the alternator via a battery, but at 60,000 rpm the turbine has picked up enough power and speed to provide 100% of the rotation and maintain continuous power output, so the alternator can function purely as a generator – from 60,000 rpm as idling speed, we run up to peak power at 120,000 rpm.”

At idle and higher, throttling is performed through levering the fuel input rate up or down, analogously to compression-ignition engines, with that fuel demand being requested and processed via an ECU (as well as a power inverter, both of which we discuss later).

“And, ultimately, we can change a lot of this as part of our modularisation approach to enabling low-cost, high-end microturbines,” Mohseni emphasises.

“If this simple cycle approach solves their issues, great; if they need two engines in one UAV, also fine; and if they want one batch of aviation microturbines with heat recuperators for long-endurance flight, as well as a second batch of micro-CHP turbines because they’re making a bunch of mobile bases for remote power and battery recharging, we have all the first-hand experience needed to do all of that.

“We’re even agnostic to the heat source for our combustor. We’ve run it smoothly on Jet-A, natural gas, propane, diesel and solar heat. We’ve also run it on a biomass-powered heat exchanger, and for those really emphatic about zero-carbon, we’ve recently tested this engine on hydrogen, both working successfully.”

Gas turbine

The compressor forms the first stage of the core gas turbine engine section. It is a conventional centrifugal compressor (also called impeller/radial compressor), consisting of an inlet pipe, a bladed impeller or rotor and a diffuser (this component being bladed/vaned like the impeller but static and mounted to the combustor to further pressurise the air and diffuse it into that subsequent chamber).

The impeller is an open-type design, featuring seven inducer blades and seven splitter blades, while the diffuser is designed with 13 blades (and no splitters).

“We also have a long nose on the impeller, which helps align it to the main shaft during integration and keep the other components in place,” Najafi says.

“Depending on the component, we can weld, bolt or push-fit components onto the shaft, with the latter approach either taking oil or shrink-fitting with different materials. Tightly bolting the impeller’s long nose to the shaft, for instance, keeps it very well aligned.”

At the time of writing, the impeller is CNC-machined from aluminium for low weight, although NEX is interested in investment casting as a reliable and repeatable (not to mention far less wasteful) method for large volume production, once demand reaches suitable levels, with Lestercast’s pricing and supplier network making them NEX’s preferred partner for such casting needs.

The combustor is designed as a single annular chamber to maximise flame propagation, with the injectors custom designed in-house for optimisation for each fuel. Najafi notes that the injectors can hence be chosen for each customer’s fuel needs if they need such optimisation, although it is not a strict requirement for multi-fuel capability; a hydrogen-optimised combustor could, for instance, still run on natural gas satisfactorily.

Stainless steel sheet is bent and formed using custom tooling to achieve the ring-like shape of the annular combustor, before being welded closed, and then the stainless steel housing is bolted directly around the combustor.

Like the impeller, the combustor may be cast in the future. Additive manufacturing (AM) could also be an option because the chamber’s hollow 3D shape can be printed as a single piece, eliminating the need to weld it shut, making for simpler overall assembly. Some prospective AM suppliers have also told NEX Power that a printed combustor would give better performance over a longer lifespan than the conventionally formed combustor.

A radial turbine sits downstream of the combustor; as mentioned, this is dissimilar to the ‘power turbine’ sections seen in those microturbine engines previously featured because those turbines rotated freely from their compressors on a separate coaxial shaft in order to drive a propeller at a lower, more efficient rpm.

“We machine the turbine from a proprietary material selection at the moment, which like the impeller is fine for prototyping and small batches, but again this is something we’d cast for higher volumes and that would open a few approaches for coating the cast turbine to improve its thermal efficiency,” Najafi says.

“We’re not settled yet on which approach we’d take, but we used a number of coatings back in our CHP days to improve the microturbine-boiler’s thermal efficiency, so we’re investigating which could work best in the context of aerospace customers. Thermal barrier coatings such as ceramic coatings could preserve the integrity of the components well.”

The turbine is welded to the shaft by Electron Beam Services in the UK, with whom NEX has worked for many years for their specialisation (in electron beam welding) and quick adaptability to the requests made of them over the term of the partnership.

Exhaust gas evacuates behind the turbine section via a conventional pipe of high-grade stainless steel, sized to avoid back-pressure, overheating, and noise and vibration that could negatively affect the turbine. Potentially helpful exhaust coatings or materials are to be investigated based on use-case (because these must take aircraft integration into account).

Foil bearing

The 15 kW GenSet’s shaft runs in two bearings, both of which are foil bearings: one placed at the end of the alternator and one located between the compressor and turbine.

Although NEX Power has benefited greatly by eliminating oil from the microturbine through use of foil bearings, the company observes that foil bearings remain rare across UAV engines owing primarily to the challenge of engineering them well.

“Air bearings are very sensitive to manoeuvres of the platform they’re on, so unless they’re designed very well, they can find it impossible to resist a very sharp and sudden movement by the aircraft – it takes a very specific design of air bearings to handle such moments,” Najafi says.

“They are, however, a common sight in APUs, which often sit centrally on an aircraft’s fuselage and use air bearings frequently, but the main engines on passenger aircraft change position more frequently and sharply than APUs, so it’d be harder for air bearings to handle the loads in those engines.”

NEX Power designed its foil bearing in-house, with the help of contracted consultants initially, after which a few years of r&d followed (including rounds of prototype testing and iteration).

The general design of such bearings consists of a sleeve, a top foil and a bump foil. The top foil runs in close contact with the shaft and, hence, is coated in a Teflon-like material for minimal stiction and scratching. The top foil must also be sized exactly to sufficiently handle the engine loads without overheating.

“Say, for instance, we go from a 2 cm length air bearing to a 5 cm one, it’ll be way better at keeping the shaft stable, but it’ll also generate a lot more resistance and more heat, which in turn will rapidly degrade the coating, causing severe damage thereafter,” Najafi explains.

“Designing these parts, selecting the coating, optimising the gap between top and bottom foil, and getting the length of the sleeve and the thermal stability of the overall bearing right are the factors we needed to balance together to get the air bearing right, and all of them must be recalculated whenever you change your engine size, engine power or shaft size.”

Electric power

The alternator has been sized to accommodate a range of battery voltages from 200 to 800 V, given that the standard voltage for an aviation battery is 540 V. However, NEX Power remains aware that lower voltages are used among UAVs, but the proliferation of EVs and demands for power density are driving development of more 800 V systems.

Despite integration of an inverter between the alternator and battery, NEX has still sought to closely match the latter two for the DC link voltage between them, for the sake of efficiency and expediency. Whichever battery is paired with the GenSet, the alternator must be able to charge it smoothly in a sustained manner, and the battery must also be able to start or restart the alternator without lags. Close voltage matching ensures minimal additional switching or stepping on top of converting the DC to AC, or vice versa.

“When we worked with a South African customer, their battery was a maximum 290 V device, so having an alternator that could cope with that was very helpful,” Najafi adds.

The alternator is provided by SycoTec, and is a radial-flux machine with permanent magnets of samarium-cobalt, being superior to most neodymium permanent magnets at performing in high temperatures. It also features an aluminium cooling case.

In addition to voltage matching, additional key specifications included ensuring the rotor sleeve was designed with sufficient internal diameter to run on the GenSet’s shaft, as well as engineering it to output up to 15 kW and to handle speeds of up to 120,000 rpm. Thermal management was also a key concern for the alternator integration, with some custom work going into optimising it for the internal air cooling enabled through NEX’s integration of it upstream from the impeller.

The inverter is COTS and supplied by BorgWarner, chosen primarily because its voltage was flexible to a similar degree as that of the alternator, and its compactness made it suitable for aviation integration (rather than bolting it onto the potentially hot engine housing, NEX Power keeps the inverter separate from the GenSet, allowing it to be installed wherever the UAV integrator has free space, or where they keep their battery). Naturally, the system being a bidirectional inverter was also key to ensuring that it could enable both battery charging and engine starting.

Engine management

As mentioned, the 15 kW GenSet is managed via an ECU, for which NEX Power is performing some final modifications. The company can also provide a FADEC system, although FADECs must be defined and based on the end-user’s platform and operations.

“Our ECU approach uses a minimal sensor count because the type of inverter we’re using already reduces the number of sensors across the powertrain through sensor-less motor-generator control,” Najafi says.

“For example, we don’t integrate any kind of actual, physical sensor on the shaft, but from reading the magnetic field of the alternator, we can estimate the shaft temperature and permanent magnet temperatures. That’s not a novelty of NEX Power, but of the SycoTec permanent magnet motor and the BorgWarner inverter technology, which BorgWarner refers to as its multi-level, high-speed, sensor-less control.

“That, along with the bidirectional power and control capability, was another big reason we chose them. It keeps our control architecture simple.”

That said, the GenSet does integrate temperature sensors on the alternator and in the gas microturbine’s exhaust manifold, enabling fine analysis of thermal deltas across the powertrain. Temperature and pressure sensors are also integrated on the diffuser, to closely gauge pressure levels between the compressor and the combustor.

Certain sensors are also integrated on the current working prototypes, purely for testing and development guidance, such as vibration sensors to evaluate their vibration output.

In operation, however, close integration of the inverter into the engine management enables close governance and tuning of speeds (and thus of fuel metering) to achieve specific levels of electric power generation.

“Through extensive testing and calculation, we know exactly how much fuel we need to inject and how much shaft rpm we need at a given moment to get the ideal voltage and current output from the alternator, be it for fast or for energy-efficient charging,” Najafi explains.

“On top of that, there’s health and longevity benefits for the engine. If, for instance, internal temperatures at the shaft and the alternator’s rotor look to be rising too sharply, the engine can quickly dial back fuel input quantities to prevent overspeeding and overheating. Quickly matching fuel quantities to both power and health requirements this way is why, despite using conventional injection components, we’ve engineered for very fine fuel control.

“In addition to sensoring the exhaust manifold, we’ve studied the thermal behaviours of the downstream metals through established testing and simulation methods, like cycling the engine with thermal paint on, to inform the next steps for improving how the ECU thermally manages at each stage.”

Also, while ensuring closed-loop control of the fuel for power output, the ECU provides thermal management after landing, typically motoring the compressor and shaft while dialling back and subsequently cutting off the fuel supply to rapidly cool the turbine and exhaust interiors with high-pressure air, shutting down completely only when the engine is thoroughly cooled (as in the case with conventional for gas turbines).

Future

As of the time of writing, NEX Power stands ready to work with customers on optimising the base 15 kW GenSet toward specific platform integrations. Its portfolio of products and capabilities also includes a microturbine-based EV portable charger product called NEXTEN, a variety of turbojets and turboprops intended for general aviation usage, and designs for other UAV-applicable turbogenerators ranging from 2 to 40 kW (together with the aforementioned stationary CHP solutions).

And, as with most other engine manufacturers, it plans further r&d pathways to maximise the capabilities of its 15 kW flagship product, particularly in better handling the perennial challenges of gas turbine operations.

“One of those involves exploring new technologies to increase the engine’s efficiency, and the other will be looking into how we can keep bringing manufacturing costs down,” Mohseni says.

“We don’t have permission to name names yet, but we’re talking with a few partners about forming a consortium to better promote and demonstrate our technology in the air, following talks from Innovate UK’s Future Flight Challenge programme, which concluded last year. Innovate UK has supported our technology throughout various programmes and, going forward, the consortium we’re planning will really showcase for larger audiences what UAVs and air taxis can achieve with our engines.”

Key specifications

15 kW GenSet

Gas micro-turbogenerator

Single shaft

Air bearing (oil-free)

Gasoline, Jet A, diesel, hydrogen, SAFs, NG, LPG

Dimensions: 450 x 180 mm

Dry weight: 10 kg

Maximum continuous power: 15 kW

Maximum output voltage: 850 V DC

Maximum output current: 55 A (RMS)

Maximum noise output: 85 dB (at 2 m distance)

Some key supplier

Power electronics: BorgWarner

Alternator: SycoTec

Electronic sensors: Mouser Electronics

Investment casting: Lestercast

Foil bearings coating: Oerlikon Balzers Coating

Turbine shaft welding: Electron Beam Services

Software systems engineering: Sonemat

UPCOMING EVENTS