In conversation: Dr Beatriz Canamary

(Image courtesy of Leon Willems and the Port of Rotterdam Authority)

Port authority

A leading expert on maritime logistics, infrastructure and sustainability talks to Rory Jackson about the role of uncrewed systems and technologies in the harbour of the future

As well as being gateways to global commerce and economic growth, ports stand as some of the world’s most vibrant intersections of critical domains, influenced by overlapping circles of regulators, international policymakers, environmental agencies, business executives and labour leaders, while simultaneously influencing each of them in turn.

But most importantly to us, they are vital ecosystems for technology, with detailed interplay between metallurgy, energy, infrastructure, logistics and, of course, naval architecture and engineering.

As a leading authority on technologies for port and supply chain infrastructure, Dr Beatriz Canamary has watched the evolving relationship between harbours and cutting-edge tech, and today sees the world’s ports as standing on the cusp of several major technical transformations – especially the adoption of uncrewed systems.

“I’ve worked for more than 20 years with large-scale infrastructure, from water supply systems, to transportation, to steel, and through working for Companhia Siderúrgica do Pecém [a joint venture between a Brazilian steel company and two South Korean ones], which was investing around US $6.5bn in developing the port of Pecém in 2012, I was introduced to – and started working in – ports,” Dr Canamary recounts to us.

“Those two companies were deeply integrated, and we built that port from the ground up. I still remember all the pipe conveyors and dedicated slab roads for part transportation, which I had to manage every day to keep the project operationally and financially viable. Eventually, I was invited to work for that port as the director of engineering, maintenance and strategic projects.”

Such projects included new investments in the port, with the largest coming from the Port of Rotterdam. Through that introduction, Dr Canamary moved to work for the latter, bringing with her a close understanding of the technical and systemic issues facing ports in the 21st century.

Such issues include severe congestion from the size and number of freighters bottlenecking port entrance channels, cost inefficiencies and investment barriers in container vessel construction (which grow higher as such vessels are built bigger to – ironically – improve operational cost efficiencies by shipping more cargo per journey), and conservativeness in scheduling new routes or integrating new technologies to reflect the risks in maritime trade (such as weather or piracy).

SeaTrain, an autonomous vehicle company based in the US, was born from its team’s collective frustration with such systemic hurdles troubling harbours the world over, and a desire to solve them through revolutionary technical transformation. Being a natural fit for its philosophy, Dr Canamary was invited to join them as COO in early 2025.

“During my years of engineering consultation, I developed decarbonisation roadmaps, digital maturity indexes and more for companies in and around ports to use – all the while, I saw that autonomous vehicles were critical enablers for all of that,” Dr Canamary says. “Today, I’m involved with several different approaches to addressing the problems ports face – but SeaTrain is perhaps the most direct one, and one that also deals with connected issues of national security and energy.”

SeaTrain

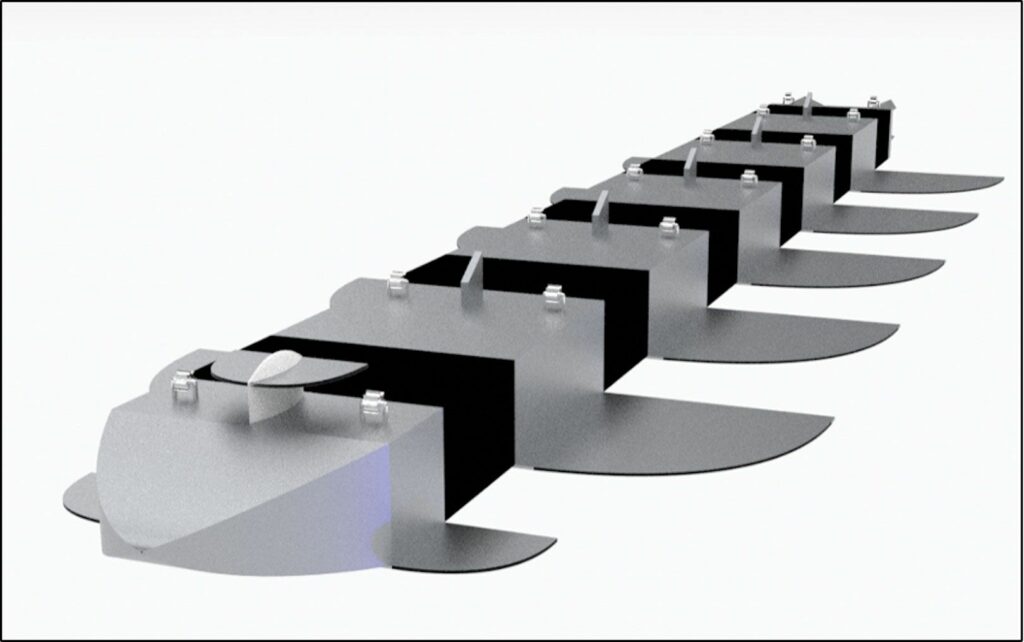

SeaTrain’s technological concept consists of large, autonomous, glider-type UUVs using variable-buoyancy engines and glider wings to generate hydrodynamic lift and hence propulsion, and composed of many carriage-like modules connected one behind the other to form an undersea freight train.

As Dr Canamary elaborates for us, the lead carriage-like module houses the train’s controls and navigation intelligence, while the tail module is designed with a hydrodynamically efficient shape to lessen drag. All the modules in between are identical cargo carriers that can be modularly connected to reach the desired total freight capacity.

All these modules are designed to be entirely uncrewed, with the system operating autonomously, and with remote oversight only when surfaced. As we have seen with many large USVs and UAVs, replacing all life-support rooms and systems with technical components and cargo optimises packing efficiency. Additionally, being uncrewed except for remote analysts and technicians (who can be trained and retained more easily thanks to better working conditions and life quality than seafarers) circumvents a significant and worsening labour shortage issue faced across shipping and harbours – an incipient focus for Dr Canamary.

“But that’s far from the only serious issue in maritime logistics that SeaTrain will resolve; another is that by operating underwater, we avoid the safety hazards and energy drain of both storm conditions and maritime traffic congestion at the surface, along with security concerns like piracy or terrorism,” she says, adding that the lead modules will integrate triple-redundant CPUs together with high-end cybersecurity and sensors for underwater navigation safety and collision avoidance. For added safety in and near ports, tugboats will tow the SeaTrain UUVs for controlled guidance, as with crewed freighters.

“Altogether, we’ll achieve much more reliability and scheduling certainty by going submersible, expanding ports’ year-round operational windows,” she continues. “Next, the modularly extendable ‘train’ configuration enables much faster construction and production than industry-standard container vessels, and avoids the ‘one-size-fits-all’ constraint that those have. We can deploy on each route flexibly, with a length and volume of cargo modules fitting the freight requirements, and therefore we’re extremely scalable in terms of costs and economics.”

As of writing, SeaTrain has been awarded three patents and a technical feasibility approval from the American Bureau of Shipping, enabling them to proceed with engineering a pilot demonstrator with small-scale modules and a minimal train length, along with r&d of the production designs. Dr Canamary anticipates that she and her colleagues will start collating bids from shipyards for commercial manufacturing within the next three months, with production to begin by mid-Q1 2026.

(Image courtesy of SeaTrain)

On the variable-buoyancy- and glider-based propulsion, Dr Canamary continues: “By achieving propulsion through buoyancy shifts via onboard compressors, and a continuous glide cycle with automated ascent and descent phases, rather than internal combustion or hybrid-electric thrusters, we can also use proprietary hydrogenerators to recharge our batteries as we move – so, we basically never need to use offshore grid energy to replenish our batteries. It’s a very, very different way of using and recovering energy in mobility.”

As well as avoiding carbon emissions in operation, the SeaTrain naturally needs no fuels. This enables it to serve remote ports where limited access to refuelling isn’t a deterrent, and also to sail through icy waters where cold temperatures or icebergs would hinder surface vessels with conventional engines.

“And those capabilities are quite appealing to military users also, for instance, in resupplying naval or air bases in Arctic or near-Arctic climes,” Dr Canamary adds. “The US administration is pushing hard to revamp its maritime industry, and there are several European port companies looking to invest in US ports, so we’re in a very good position to start growing this solution here in the US and then to go global.”

Connected and sustainable

Given the systemic nature of the problems throttling harbours today, Dr Canamary researches and advocates many other technologies – not unrelated to autonomy – as critical enablers of long-term maritime sustainability.

“Whatever the type of freighter, autonomous navigation systems – not just for uncrewed, intervention-less sailing but continuous, AI-driven analysis of environmental and traffic data – stand to revolutionise dynamic route optimisations and collision avoidance at sea, as well as achieving just-in-time arrivals where possible to cut fuel emissions, congestion and idling or storage costs,” she comments. “So, harbours need dedicated suppliers or workforces for developing those tools and integrating them into real-world operations.”

Digital twinning and simulation platforms are also increasingly touted for real-time modelling of vessels, cargo flows and port infrastructures to realistically stress-test and optimise traffic and logistics plans (potentially with AI analytics), thereby saving immense costs and time for ship operators, harbour owners and other stakeholders.

“AI will also be key for predictive maintenance because, for really huge container vessels, preventing subsystem failures before they occur can save hugely on running costs and asset downtimes, and help a lot with extending asset lifetimes; and if it works for vessels, it can work for warehouse vehicles, cranes, straddle carriers and other areas of the maritime ecosystem,” Dr Canamary adds.

“But an overarching problem behind all these areas where useful new tech and personnel could come from, is that of interoperability. Too often, technologies are being developed in silos; a few companies I’m watching are trying to integrate simulation platforms, AI maintenance tools, uncrewed systems and more together, and it’s very challenging for them.

“As a hypothetical target or baseline, a team focused on achieving seamless hands-off control of autonomous freight vessels through, say, digitally connected berth management, cargo handling, and inter-land logistics systems, could really increase cargo throughput on a global scale one day.”

More challenging to overcome will be the aforementioned conservativeness of ports to invest in new technologies, even to achieve long-term sustainability. Part of this comes from ports assuming that the platforms offered will not integrate smoothly with existing infrastructure; but Dr Canamary anticipates that enabling an increased flow of open- and innovation-minded people into spheres related to maritime logistics will lead to the sorts of discussions, explorations and partnerships necessary to enable the autonomous, sustainable harbour of the future.

(Image courtesy of SeaTrain)

“Moreover, harbours are dealing with immense competition, trade wars and scrutiny from their surrounding communities, on top of mounting environmental regulations in most corners of the world,” she notes.

“So, if autonomous tech and other advanced solutions come not just as interoperable, connected systems but also as pilot programmes that bring clear cost, time and emissions savings, as well as a high ROI [return on investment], while still creating lots of jobs and supportive networks, then they become urgent tools for ports to acquire, rather than isolated things developed in a bubble that port owners will stay dubious of.”

The next generation

For the dream of fully autonomous, zero-emission, socially and economically just harbours to come true, Dr Canamary eyes a few other specific steps as key.

“In terms of regulatory modernisation, we need to update the COLREGs [International Regulations for Preventing Collisions at Sea] with specified guidelines that uncrewed vessels can follow, and we need to establish clearer certification pathways for autonomous systems to be allowed to operate in international waters,” she says.

“On top of that, innovation is more than just r&d into new solutions and subsystems. Being able to scale manufacturing of freight vessels and reduce their per-unit costs could enable new funding structures, like business models where uncrewed cargo carriers could be leased or chartered, unlocking ‘technology-as-a-service’ models for capital-light operators.”

On a wider scale, Dr Canamary views accelerated collective learning as vital to growing awareness and updating of new technologies, and collaborations between tech providers, vessel operators and regulators for the sharing of pilot data will be vital to this end. Naturally, infrastructural readiness will be indispensable for some trial programmes, and for taking them from demonstration phases to commercial integration and scaling.

“A lot of ports are specifically needing revamps and upgrades in terms of charging infrastructure, automated maintenance tools, and both mechanical and electronic support for docking autonomously, not to mention smart connectivity and control networks to ensure rich tracking, monitoring and safety for uncrewed vessels. It’s almost tiring just thinking about the amount of work it’s going to take,” she laughs. “But it also means serious opportunities for anyone who comes forward to take part.”

On that note, Dr Canamary refers again to the aforementioned problem of labour shortages in harbours the world over, and the key skills that are accordingly lacking when it comes to comprehending, integrating and managing new technological enablers.

To resolve both issues, her paramount focus for the next several months will be on a new company she founded earlier this year, LinkGenZ (recently integrated into Next Wave Systems, which now operates as the consolidated entity), intended to bring Generation Z interns and graduates into the maritime space.

“Maritime industry is dominated by experienced older people, but there’s a lack of attention being paid to the transition to the next generation; worse, young people know little to nothing about the maritime industry and see basically nothing of it in their usual day-to-day,” Dr Canamary says.

Next Wave Systems’ technical focus is to develop ‘gamified’ tools for linking young engineers’ skills to potential ideas, project concepts and places of employment – whether they want to launch a start-up or work in an established business – connected to the maritime industry. Combined with that is a community hub for networking with like-minded persons from maritime organisations and Dr Canamary plans to provide mentoring to guide them personally.

“I teach a course at Florida Polytechnic University – just as an adjunct because of how busy the corporate side of my activities keeps me – but through my teaching, I’ve seen first-hand that younger people absolutely love working on and with new technology,” she says.

“Contrast that with the rigidity of the older generation when it comes to adopting new autonomous, digital and sustainable technologies, and you see just how important it is to start building those bridges to address our long-term issues.”

Dr Beatriz Canamary

Dr Beatriz Canamary grew up in Brazil and graduated from the University of Fortaleza with a Bachelor’s degree in Civil Engineering in 2002, later achieving a Master’s degree in Engineering from the Federal University of Ceara in 2013 while working as project manager for Concremat Engenharia e Tecnologia, where she spent seven years managing multiple projects across water, sanitation, transport, oil & gas and other industries.

After working for three years at Companhia Siderúrgica do Pecém, she became executive director of Pecém Complex, and gained a business degree from Harvard Business School midway through her tenure at Pecém. Thereafter, she provided various climate and legal consultations in her capacity as an engineering expert, and achieved her Executive Doctorate (of Business Administration, Multinational Enterprises and the UN Sustainable Development Goals – The Role of Seaports) from Crummer Graduate School of Business Rollins College, Florida, in 2023.

In 2022, she founded SuRe Strategy, where as CEO she continues to spearhead the company’s work in advising ports and industries on various pathways toward modernisation, optimisation and systemic resilience. She additionally joined SeaTrain Technology as COO in 2025, where she leads the company’s UUV development from concept to commercialisation, and founded LinkGenZ and Next Wave Systems to promote career paths into the maritime industry among younger people.

Whenever possible, Dr Canamary also serves as Adjunct Professor of Logistics & Sustainability at Florida Polytechnic University’s Department of Computer Science and Business Analytics, teaching courses on supply chains, data analytics and sustainability, as well as representing the university on panels and in partnerships.

UPCOMING EVENTS