High Eye Airboxer

(All images courtesy of High Eye)

All eyes on me

After many years of rigorous development and optimisation, High Eye is poised for series production of its Airboxer helicopter UAV, starting with major defence customers. Rory Jackson reports on how they got there

In the age of high-tech systems, where established OEMs and new start-ups alike compete to grab headlines with claims of what their products can do, it is easy to fall prey to the temptation to constantly replace parts and components with the latest, most cutting-edge subsystems, and to release and re-release over and over.

However, when it comes to serious, professional aviation, technological advancement must be strictly balanced against technological maturation. Airworthiness means having a minimum level of confidence that your aircraft will not be at risk of faults or failures before a very high number of hours have been flown. Therefore, rushing a launch or re-release, with (for instance) all-new, untried and untested computers or battery technologies onboard will not impress flight safety regulators; years of steady-paced testing and development, spent ironing-out bugs, building-in redundancies and reinforcing an aircraft’s safety case, will.

Netherlands-based High Eye understands this closely, having begun its journey to design helicopter UAVs for maritime domain awareness, terrestrial ISR and other professional applications roughly 12 years ago. In particular, its engineers have sought to create a long-endurance, weather-resilient alternative to small multi-rotors, while still fulfilling a less heavy-duty niche than the larger, heavier helicopter UAVs of Schiebel, Saab and the like.

From its headquarters in Dordrecht, High Eye spent this interim period gradually working toward the full confidence and assurance it has today, satisfied that it has built its flagship product to be as capable, efficient and safe as can be. That product began life as the HEF 30 UAV in the early 2010s, later becoming the HEF 32, and evolving into the Airboxer a few years ago.

Today, the Airboxer stands as a 1839 mm long, 632 mm wide and 575 mm tall helicopter, with a 32 kg MTOW and up to 7 kg of payload capacity. The fuel load and the two-stroke, air-cooled engine (and High Eye’s transmission) enable typical endurance of four hours.

As Joost de Ruiter, CEO of High Eye recounts, “We originally intended to make a helicopter that could fly for 2-3 hours and carry 5 kg, but a helicopter is an unforgiving aircraft to engineer. As our ground and flight tests went into the thousands of hours, we hunted-down more potential faults, built-in more redundancies and workarounds, added more engine power to carry those safety measures, and so found ourselves far surpassing our original performance targets.”

Now decisively into its scaling-up phase and steadily adding to its 1500 m² production floor in Dordrecht, the company is working on its first small order of Airboxers for the Netherlands MoD, after which it will supply three far larger orders signed under NDAs: one for an MoD located in the EU and the other two for additional defence ministries elsewhere in the world.

Slow burn romance

The first two years of High Eye’s business operations were largely spent developing the HEF 30. Although the system performed to the satisfaction of its developers and prospective users, High Eye was determined to continually add redundancies throughout the helicopter, in the interest of safety and future certifiability.

“That meant the UAV became heavier over time, which in turn meant we were demanding more and more of the engine. So, after roughly two years of r&d we upgraded to a bigger engine,” de Ruiter recounts.

“The reason that’s especially important within the context of our product development timeline is that the HEF 30 was named for the displacement of its engine – a 30 cc unit. So, the HEF 32 was effectively born when we switched to a 32 cc engine.”

Operations and r&d with the HEF 32 continued for about three years until, as before, integrations of more subsystems and more weight began to place an excessive burden on the engine. An increasing incidence of overheating problems motivated High Eye to look beyond the 32 cc engine, and a fresh round of development testing ensued, in which the Dutch company trialled several new engines (at least five different models, to its recollection) from various suppliers to see which performed best.

“We know from experience that trying to simulate the engine’s performance from one of the supplier’s CAD files never yields accurate results, so we just bought one of each engine, measured everything we could about them on the ground, flight-tested them extensively and, where possible, we tried to build up a productive relationship with each of the different engine suppliers,” de Ruiter says.

The result of this work (which came roughly three years ago) was that the HEF 32’s engine was swapped out for an 80 cc, air-cooled, boxer twin engine, and the UAV was named the Airboxer (sacrificing the displacement-based moniker to emphasise a couple of the engine’s other characteristics).

“All other subsystems on the HEF 32 had worked together very well, and replacing the engine did resolve the overheating issue, but integrating a new engine then required building a new gearbox and reconfiguring the drivetrain all over again. So, the end result was practically a whole new helicopter,” de Ruiter says.

“Looking at the Airboxer, you might’ve thought it wasn’t a very different aircraft to the HEF 32, but it sports three freshly-designed blades, six actuators on the main rotor, three on the tail rotor, an all-new engine and ancillaries, a new gearbox and, overall, is much heavier than its predecessor.

“And although the HEF 32 and Airboxer both took about the same length of development time so far, we’ve gotten better at condensing our r&d loops over the years. So, we find we’ve been able to do our tests, improvements and optimisations at a much faster rate with the Airboxer than we did with the HEF 32.”

Much of the subsequent work on the Airboxer continued to revolve around certifiability, particularly the creation of a main rotor design which could, as mentioned, integrate six actuators (rather than the more traditional three-servo approach), and a tail rotor design that uses three actuators instead of a conventional single-servo design.

“That adds safety, but also weight; and the same goes for our approach to internal wiring harnesses,” de Ruiter muses. “If you want to avoid EMI-induced faults, you need military-grade connectors and cables, and those are all much, much heavier than the sorts of wires and plugs from consumer- or hobby-grade suppliers. On top of that, having a gearbox which would last far longer than 50 flight hours meant designing it to be very strong. So, overall, that meant weight optimisation has been practically as important as safety optimisation, to ensure the Airboxer would be not just reliable but efficient too.”

Boxing anatomy

Starting from the outside, the aircraft flies using a two-blade tail rotor at the rear that connects to a gearbox via a lightweight carbon fibre driveshaft, and a three-blade main rotor at the top, which also runs into that gearbox downwards.

“The gearbox is just about the newest component in the aircraft; we engineered it fairly recently, as a much larger and stronger replacement to the previous gearbox, which moved the CoG a bit further back, but the result has been much better counteracting of all the forces coming from the engine and rotor systems,” explains Erik Starmans, COO of High Eye.

“Developing this gearbox took exhaustive hours of testing on our test bench, iteratively replacing and modifying parts to get better and longer-lasting performance, including drilling holes in some gears to improve how oil splashes and lubricates throughout, and adjusting bearings here and there.”

The gearbox is driven by an 80 cc two-stroke boxer twin, and each cylinder features a sizeable stainless steel exhaust pipe running backwards along the fuselage. Forward of these, inside the nose, is a central avionics unit that contains the autopilot from UAV Navigation-Grupo Oesia and some other electronics (all within an EMI-shielded enclosure), with a few additional sensors for aiding flight and navigation installed elsewhere across the airframe. The fuel tank wraps concentrically around the gearbox, ensuring that the CoG and centre of balance do not change significantly as fuel is consumed over mission durations.

The engine, drivetrain and fuel tank mount to a frame inside the aircraft that enables all three to collectively form a structural member, providing structural integrity to the rest of the aircraft. The frame attaches to the outer housing, as does a damper, on which the central avionics unit is mounted.

“All the structural components are made from flexible carbon composites to withstand the forces endured during flight,” Starmans says.

“The tail boom is fitted as a shell or sleeve around the actual tail rotor shaft, the latter connecting to the gearbox and the former therefore both protecting the internal components from outside elements and forces and securely bonding the tail and fuselage elements together.”

The tail boom and top cover together form the aforementioned outer housing. The tail boom is made from carbon composite, but the top cover is a fibreglass composite for the sake of RF transparency. The landing gear was previously made from a hard composite, but as High Eye’s flagship UAV integrated more redundancies, power and weight, the company switched to a more easily flexed Nylon material (because crash tests increasingly indicated a risk that the legs might be driven up into the fuselage during especially hard landings).

VECTORed trust

Flight control commands in all Airboxers are processed and output by UAV Navigation’s VECTOR 600 autopilot computer, which includes the Spanish company’s proprietary (although still configurable by end-users for all requirements) software. The partnership between High Eye and UAV Navigation stretches back through to the HEF 30, the latter having notably made extensive efforts to program effective communication and flight management not only in fixed-wing and multirotor UAVs, but also in aircraft with single main- and tail-rotors – a rarity among autopilot suppliers a decade ago.

“They were very proficient in engineering and evolving their autopilot for helicopters. That plus their very consistent and good technical support are why we confidently chose the VECTOR series over and over, and why the partnership has lasted throughout our history,” Starmans comments.

“Even today still, there aren’t that many helicopter-dedicated UAV flight controllers, and we know firsthand that UAV Navigation’s system is stable and provides very fine, smooth control and easy interfacing with the Airboxer.”

Among the VECTOR 600’s most notable flight control functions suited to flight safety in helicopter UAVs is the autorotation function, together with the capacity to include alternative and backup landing locations during mission planning. Additional safety qualities key to certifiability for UAVs in general include the integration of dual-redundant IMUs, CPUs and power, a flight termination system, and software developed in accordance with DO-178C standards covering safety considerations for airborne vehicle and equipment certification (not to mention the hardware having been tested to Mil-Std 810 and Mil-Std 461 on environmental and EMI protection, respectively).

As indicated, the Airboxer integrates six servos on the main rotor and three on the tail rotor as well as one in the engine throttle. Overall, this gives High Eye’s UAV the most extensive actuation redundancy of any helicopter we have featured to date, with the main rotor servos functioning as a redundant system. The tail rotor also features three servos to enable redundancy, given that the conventional approach has most helicopters feature just one tail rotor actuator.

“If one servo fails, the user immediately gets an alert via the UAV Navigation’s autopilot down to their Visionair GCS, which we use as our ground control interface software for its inherent integration with the VECTOR,” Starmans says.

In the absence of certification- or approval-based required actions, High Eye leaves it to the user to determine what the next action should be following a rotor servo failure. Training or routine monitoring missions, for instance, indicate that there is little to gain from continuing flight in such a circumstance other than potentially endangering the UAV or people nearby. Alternatively, a servo fault during a maritime ISR mission strategically vital to a nation’s interests would naturally merit postponing the safety landing; based on High Eye’s flight testing, it judges that the UAV can still fly safely with just four working actuators.

“The Volz servos are very robust in general, and the product we use across both the main and tail rotors has a clutch element inside for extra reliability. In the rare event that a failure should occur, the clutch in the failed servo disengages so that its partner maintains full control over the linkage to the swashplate.” Starmans adds.

“The throttle servo is also a Volz device, but not the clutch-equipped model we chose for the rotors – just one of their more standard ones. Volz have consistently provided good technical support whenever we’ve needed it, as well as good products, so we see no reason to look into any other actuators for the foreseeable future.”

The VECTOR provides centralised control for veritably the entire UAV, and is connected to a power management module, with both co-located in High Eye’s central avionics unit. That then connects outward to the servos, powertrain, payload, comms and the remainder of the subsystems.

The autopilot integrates a field-programmable gate array that handles communications to the rest of the UAV peripherals via a network that includes several device-dependant protocols: an Ethernet link that connects it to the main radio for GCS commands and telemetry, PWM lines that deliver commands to the servos (having provided robust performance so far) and other sensors and avionics that interface using serial connections such as RS-232 and -422 as well as CAN bus.

“And to protect against EMI, as well as the harsh environmental conditions both inside and outside the UAV, we predominantly use high-grade ODU connectors, with cables made in-house to enable very specific lengths and exact bending points, so that there’s no shearing, wear or excessive lengths of harnesses anywhere inside the aircraft,” Starmans adds.

Navigation systems

In addition to providing dual IMUs, the VECTOR 600 integrates a 72-channel GNSS receiver compatible with GPS, GLONASS, BeiDou, and Galileo signals, as well as the SBAS and Japan’s regional QZSS constellation. The two are integrated within UAV Navigation’s air data, attitude and heading reference system (ADAHRS), together with an altimeter. The ADAHRS’s data support the Airboxer’s real-time navigation and waypoint-based mission planning needs (with up to 400 waypoints storable in the autopilot’s log at a time), and the flight controller also comes with an internal three-axis magnetometer for magnetic field compensation.

“The Airboxer is equipped with a dual GNSS compass to calculate heading when the helicopter is hovering stationary, ascending or descending within a given GNSS coordinate, or flying sideways or backwards,” Starmans says.

“For heading refence redundancy, we have integrated a second magnetometer in the tail boom, which in combination with our two pitot tubes – one on the left and one on the right side of the aircraft – means we can estimate the heading, even in GNSS-denied environments.”

For added non-GNSS navigation capacity, the VECTOR autopilot has been engineered with EMI-resistant components and estimation logic specifically to mitigate the impact of certain high-power signals consistent with GNSS jamming or spoofing, and to enable sufficient dead-reckoning to compensate for GNSS losses. It also integrates camera-guided and referenced navigation capabilities; hence, the Spanish company’s VNS01 system can be integrated to enable vision-based localisation during GNSS outages.

A laser altimeter – specifically, a LightWare LW20/C – is also integrated for added safety during autorotations (to support with the flare height) as well as landings, chosen by High Eye for being the smallest and lightest ground-referencing altimeter system it could find (and also recommended by UAV Navigation, which had good experiences with the model and supplier). This product’s small size also enabled High Eye’s engineers to install it in the space-constrained middle of the Airboxer’s underside, giving a better point of reference than when placed in the more spacious nose or rear.

Communications

Omnidirectional antennas for communication are placed as standard within the front landing gear. This is a convenient integration because it keeps the antennas far away from other critical components and sources of EMI, and also ensures that they are pointing directly downward to maximise their coverage area.

“That’s how we configure comms with our standard radio. Of course, customers will have their own preferences as to radios and antennas, and wherever possible we try to integrate everything inside the body of the aircraft, but we can mount antennas, radios and sensors externally in different ways if needed,” Starmans notes.

The radio High Eye predominantly uses for comms with the Airboxer is one of Silvus’ StreamCaster systems, which comes as a component set that the Dutch company uses to enable its short-range comms with the ground. For medium- and longer-range comms, it tends to use its own ground directional antennas, constructed using COTS dishes, customised ground planes and integrated pan/tilt actuators for adjusting the dish’s direction as the UAV moves.

“When working with a new customer, we push to understand their comms requirements as quickly as possible; predominantly, we tend to push for the Silvus systems, because we’ve integrated and used them successfully for a while. But if either a different radio or multiple redundant radios are requested, then our engineers figure out the optimal integration early on, to optimise the new Airboxer design, before we go on to manufacture it as a batch or series,” Starmans explains.

Mission payloads

Generally, High Eye maintains a flexible approach to payload sensors because the primary target of any custom engineering plan is achieving the customer’s preferred mission capabilities. “Typically, those customers with a good idea of what they want to do will approach us with a payload from a manufacturer that they have either good experiences or a contract with, often including well-known small gimbals like NextVision’s, and for those who don’t have a preferred supplier, we have to remain mission-focused and maybe help find the perfect payload for them,” Starmans says.

Rather than lock-in a specific payload bay, the Airboxer can integrate payloads in a number of places based on mission utility. Most often, this means installing either directly underneath the nose with a very short connection distance to the central avionics unit, or on a sliding plate further forward, which means moving the CoG slightly forward of the optimal place, but getting a more unrestricted FoV for the payload.

Mission-critical intelligent functions such as gimbal target tracking and object recognition are provided via UAV Navigation’s Visionair GCS software, with data analytics transmitted and visible to the user’s interface, and the Visionair SDK enabling end-users to customise functionalities and include native extensions. Customer requests for new intelligent features are handled initially by High Eye (as the platform designer and manufacturer), who liaise with UAV Navigation as needed.

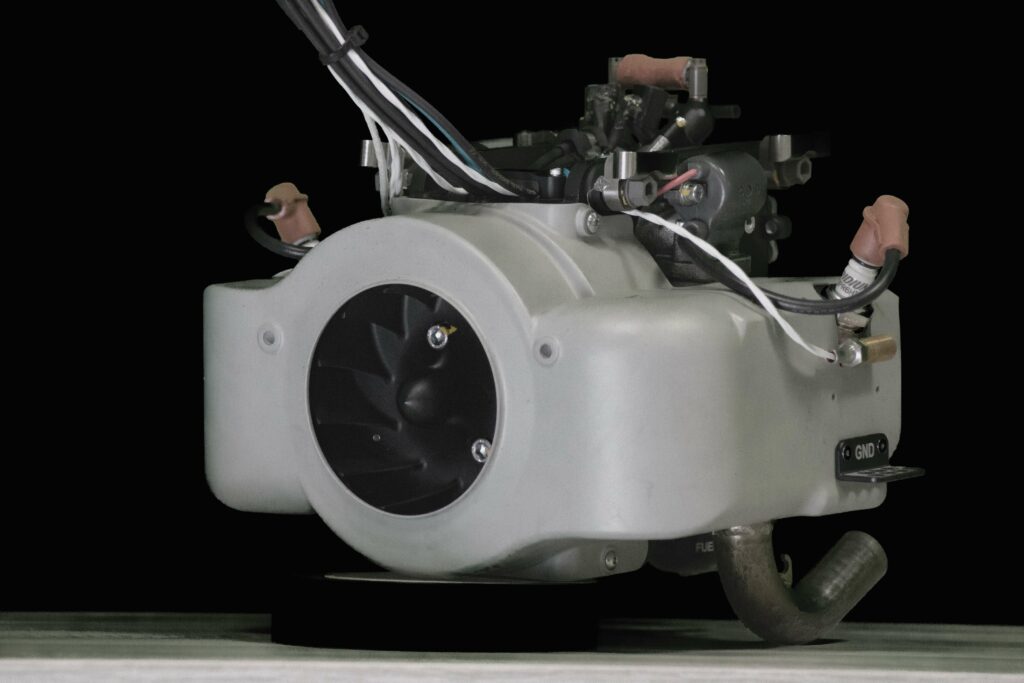

Fuel- and air-cooled boxers

As indicated, the Airboxer’s engine is a boxer twin two-stroke displacing 80 cc. The engine is managed by FADEC, and features dual injection systems for redundancy, together with a thermal management strategy that uses both forced-air and fuel as cooling media. While not entirely produced in-house, the engine is delivered from Zenoah, disassembled, and then remanufactured with several key part replacements, including the installation of new bearings from SKF to withstand the high temperatures and shaft speeds required for High Eye’s operations.

“It outputs up to 5.5 kW in typical operations, and has a top crank speed of 9200 rpm – but the top speed doesn’t produce our peak power, so we actually either work faster or slower than the peak power speed. And if ever an engine reading should be slightly off, we can easily throttle back to a lower rpm and depending on the operating envelope, that can either reduce our power too, or actually increase it,” Starmans says.

Given the lack of passive air-cooling for rotor-wing aircraft, active cooling was a critical necessity but liquid cooling was deemed overly heavy. Hence, rather than putting water-glycol, pumps, filters, radiators and potentially a tank onboard the Airboxer, a single fan placed under the nose draws in, compresses and rams air over the cylinders and heads. Significant CFD work and iteration went into optimising the fan to ensure that the swirl of air output not only extracts heat from the engine metal, but also flows throughout the other subsystems, particularly to provide cooling of gear oil.

“Keeping the active cooling to one fan also makes for a mechanically simpler powertrain, which is good from both engineering and maintenance optimisation perspectives; even the selection of a two-stroke rather than a four-stroke was principally driven by the comparatively lower number of moving parts that you get in a two-stroke,” Starmans explains.

To further manage the temperature of the engine in certain parts of the flight envelope, the ECU will actively enrich the fuel-air mixture to the point that unburned fuel extracts heat out of the combustion chamber and directs it to the exhaust as it passes from there (a complete burn would generate considerably higher heat, including at inopportune or unsafe moments).

“Granted, two-strokes might not be as fuel-efficient as four-strokes, particularly when you use some of the fuel for cooling the engine, but that’s offset by the maintenance advantages, and in return we get a very powerful engine relative to its size and weight,” Starmans continues.

“It took a lot of optimisation to get to the comfortable level the engine’s at now – even as recently as three years ago, there was no UAV engine that quite achieved what we wanted.

“Hence, why the engine needs to be remanufactured in-house, and why there’s a custom set of exhaust pipes, specially designed by High Eye and produced in Germany by Zimmermann extending back from the engine along the undercarriage, which are also key to how we maximise our power output.”

High Eye has continuously used fuel pumps from HP-Tech GmbH in Austria, having yet to experience a fault with any of them over its years of operation. Similar satisfaction and support have been found by the Dutch aircraft manufacturer in using Power4Flight’s accumulator (which integrates a fuel pressure transducer to enable finer pressure control) and Pepperl+Fuchs rpm sensors in its powertrains.

The fuel tank is an additively-printed hard-shelled component rather than a bladder-type tank, made from a proprietary material and also coated in an undisclosed system – High Eye having gone through very lengthy development loops (and many rigorously-tested and rejected tank prototypes) to identify optimal materials. Those needed to provide sufficient strength for withstanding both the engine vibrations from below and the rotor vibrations from above. Weight minimisations were also critical, because any material that was too light would inevitably suffer cracks (and hence leak fuel) at some point.

Metal gears

As previously mentioned, the gearbox is (as of writing) the most recently-updated major component in the Airboxer, and has changed several times over the years and the iterations of development. In the present configuration, it reduces the engine shaft’s speed from 9200 to 5076 rpm at the main gearbox shaft. The

main rotor shaft and tail rotor shaft each run off dedicated gears on that shaft, which convert its 5076 rpm to values of 1250 and 7600 rpm for the main rotor shaft and tail rotor, respectively.

“Upon the Airboxer’s inception, we’d used a smaller gearbox that evolved out of the HEF 32, but the forces imparted from the bigger engine and new rotor configuration were so high that we redesigned it, for both main and tail rotor outputs, to better withstand those forces,” Starmans says.

“Every transmission of power, from the crankshaft to a gear, to another gear and so on, generates torque, shock and vibration running up to the gearbox from the engine. Altogether, the drivetrain has an engine running at 9200 rpm, an alternator running off the engine at 3000 rpm, a main rotor moving at 1250 rpm and a tail rotor spinning at 7000-8000 rpm.

“All those different rpms are created via gears, and every interaction of one gear with another means generating forces tangentially, axially and radially, all of which are hard enough to endure when the gearbox is steady. Add flight into the equation and suddenly you’ve also got forces like the inherent drag created as blades cut through the wind or the extra drag from pitching the rotor blades and the resistance that imparts down to the gearbox. You’ve also got the inherent counter-rotational torque from the main rotor that the tail rotor has to counteract, and that means a constant source of stress running from the tail, along the tail drive shaft and into the gearbox’s tail end.”

Small wonder then, that much of High Eye’s last few years of r&d have focused on redesigning the gearbox, from the casing to the driveshafts, gear switches and gears, with High Eye trialling these on its test bench throughout 2024 to see what further configuration changes were needed, with the final result being a complete redesign of what the Airboxer had started with.

Optimising the system for strength-to-weight has resulted in the use of an aluminium alloy housing, which represents the biggest and heaviest single component, and hence the lightest metal in the gearbox. Titanium shafts are used for maximum strength with slight flexibility, together with gears made from high carbon steel – temperature hardened for the running surface of the gears – ordered COTS but modified in-house to meet High Eye’s specifications, including drilling additional holes in the gears for better oil passage.

Rotors

Each main rotor blade is 870 mm long, with an asymmetric design created through consultation with NLR (also in the Netherlands) to optimise performance. The blades from main to tail hub are constructed from fibreglass composite, with the main rotor blades integrating foam cores for optimising their strength-to-weight ratio, together with lead bars as anti-flutter weights.

“We also have small but thick plastic, high-speed tape placed along the leading edge for extra protection and lifespan, against both gravel and dust from the ground, and from precipitation in flight,” Starmans says.

“KVE Composites was able to make the blade to our specs nicely, and even produced them such that all three in every set were perfectly weight-balanced to each other. That’s very necessary, since using blades with unequal weights causes serious imbalances in the hover field when activating the rotor system.”

The three blades, together with the main rotor head, mast and linkages, are arranged in a fully articulated rotor system (a not-unconventional sight among helicopters with three or more blades), while the tail is a semi-rigid rotor.

In a fully articulated rotor configuration, each blade can feather, lead (or lag) and pitch independently of the other two. Compared with rigid and semi-rigid main rotors (more common in two-bladed helicopters), a fully articulated main rotor enables much finer flight control response; hence, the company’s decision to go from a two-bladed main rotor to a three-bladed one has greatly improved the Airboxer’s controllability over that of the HEF 32. It also yields some vibrational benefits over the other two rotor configurations, with obvious benefits that can follow for the customer’s ISR data quality and running maintenance costs.

“Allowing the blade to flap a little bit also helps to increase and decrease the angle of attack to keep the lift constant, and having more lead or lag is important because even when the blades are spinning, each blade has a tendency to move forward a little bit. So, allowing that movement helps absorb loads and reduce stress and vibration,” Starmans says.

“That, plus a similar freedom for feathering given by the hinges, means overall we’ve maximised how smoothly-operating our rotor field is. It’s well-established technology already in crewed aviation. Our blades also are statically-balanced with little to no dynamic tuning, which means we get inherently a quite well-running system.”

GCS to GCS

Interfacing with Airboxer for operations management and mission configuration is performed via the Windows-based Visionair GCS software from UAV Navigation. As well as enabling configuration of the autopilot and ADAHRS, users can plan each mission with multiple flight paths (including via autogrid-based generation of flight plans), landing sites and waypoint-specific actions with mid-mission modifications.

Through the software, users can also control payloads, engage in non-GNSS referenced navigation, and track real-time ATC data with geofencing and ACAS functionalities for responding to air traffic requirements where needed. Missions can also be exported to Google Earth for near-real-time visualisation if preferred, and data can also be exported to FlightGear Flight Simulator for synthetic 3D video representation of Airboxer’s surroundings.

-724x1024.jpg)

Meanwhile, High Eye has developed its own GCS hardware platforms to host the software in a physical form factor familiar to experienced helicopter pilots. One of these is a portable box-type solution constructed around a Durabook ruggedised laptop, and integrating a UAV Navigation control interface device, together with joysticks for cyclic and collective inputs, numerous buttons and switches, and outputs for connecting to the pertinent ground antenna as well as other peripherals where needed.

“We’ve been developing our GCS since the HEF 32 to pass the bar for trained MoD and naval officers, but we don’t wish to be locked-in with legacy systems as more and more industries and organisations are becoming first-time UAV operators, more familiar with simple multi-rotor control than the complexity of piloting helicopters, so we’re weighing up the best ways to simplify the system,” Starmans says.

“The simpler and smaller your GCS, the easier missions get, and the more autonomously the aircraft should be able to do its job. So, the mobile GCS is a bit chunkier than we’d like from a logistical standpoint, but its functions are all quite optimised for what it’s needed to do so far.”

To further assist different CONOPSs, High Eye also installs its GCS systems into vans, supplying these vehicles as mobile operations centres, which can then integrate larger screens and control layouts given the resulting ease of transport. However, the initial UAS deliveries to the Netherlands MoD will incorporate just the standard, smaller GCS units, including at least one simulator version of the GCS, principally to enable trainees to familiarise themselves with managing the Airboxer’s missions, and with taking manual control when necessary.

Higher and higher

To prepare for its official status as an OEM (and no longer having engineering be its primary activity), High Eye has updated all of its SolidWorks assets to match its finalised bill of materials, rearranged its logistics to suit manufacturing and assembly requirements, and configured its production floor for lean workflow processes – at least initially.

“There’s always the temptation to explode with your purchases of new machinery, jigs and personnel, but we’ve gotten this far by being smart and not jumping the gun. So, we’ve been spending time finding the absolute best production engineers, three of which are now actively at work, and we’re finalising choices of an assembly technician to provide the last bit of assistance with production for now,” Starmans says.

“Once we’re confident that the initial production flow functions well, and is a stable basis to work from, then we’ll talk about copy-pasting it, expanding it outwards and tuning it where needed to utilise the production space to the best as can be.”

Despite largely switching from engineering to manufacturing going forward, High Eye has no intention of stopping its r&d. “Development is part of our DNA, so we have to continue improving our product however we can,” de Ruiter muses.

The company anticipates focusing particularly on extending the Airboxer’s flight endurance and effective comms range, as well as integrating new and valuable payloads to match or get ahead of customer demands.

“We would also like to grow our portfolio. We’ve gained a lot of specialist expertise in making this fuel-driven ISR platform, so extending our product offerings with more ISR UAVs – whether built by us, or by future foreign partners looking for an experienced distributor in the EU, capable of re-engineering them for certifiability in Europe – feels right to us,” de Ruiter continues.

“But before all of that: our first bridge to cross is scaling-up. We want to be lean about it, but our customers also need us to do it quickly, and to a much bigger extent than we’d been expecting before all our contract signings. So, first things first, it’s time to roll up our sleeves, get our hands dirty and start building; which we’re of course quite pleased about. We have, after all, been waiting for this for quite a while.”

Key specifications

Airboxer

Helicopter UAV

Two-stroke, spark-ignited boxer twin

Three-blade main rotor

Two-blade tail rotor

Dimensions: 1839 x 632 x 575 mm

MTOW: 32 kg

Payload capacity: 7 kg

Maximum endurance: 4 hours

Maximum flight range: 360 km

Engine displacement: 80 cc

Power output: 5.5 kW

Some key suppliers

Autopilot: UAV Navigation

Radios: Silvus Technologies

Gimbals: NextVision

Accumulator: Power4Flight

Fuselage: Refitech

Tail boom: Refitech

Rotor blades: KVE composites

Fuel Sensor: Reventec

RPM sensors: Pepperl+Fuchs

Laser altimeter: LightWare

Landing gear: Shapeways/Manuevo BV

Ducts: Shapeways/Manuevo BV

Fairings: Shapeways/Manuevo BV

Bearings: SKF

Connectors: ODU Connector Systems

Fuel pumps: HP-Tech GmbH

Servos: Volz

Engine: Zenoah (remanufactured in-house)

GCS laptops: Durabook

Exhaust pipes: Zimmermann

UPCOMING EVENTS