Hecto Drone HD-606

(Images by Runólfur Geir Guðbjörnsson – courtesy of Hecto Drone)

Hexacopter horsepower

Once a provider of simple drone services, this Danish company now designs, manufactures and sells industrial-quality, hybrid-powered UAVs — and engineers highly airworthy small powertrains too. Rory Jackson investigates

Back in 2017, the team behind Denmark-based Hecto Drone was performing aerial mapping services using COTS drones and equipment – and rapidly finding such work to be both laborious and unpleasant, as CEO Andreas Siggaard recounts.

“We were doing NDVI [normalised difference vegetation index] measurements for agricultural customers, flying a lot of square kilometres, which meant a lot of landing, battery hot-swapping and other maintenance. A six-to-seven hour survey session of a maximum of 25 minute flights could mean 10–20 instances of hurried turnarounds, each accompanied by dashing into our vehicle to drive over to the drone’s next landing point if we were surveying an especially large field,” he says.

Between these many landings, the operators would check incoming telemetry and charge battery packs using a mobile Honda generator positioned nearby. It quickly occurred to them that their lives would be far easier if that generator were on the drone instead, meaning that the drone could go off and fly for five hours by itself.

Unfortunately, the generator produced only 2 kW while weighing 21 kg – a deeply insufficient power-to-weight ratio, as the team discovered upon physically mounting it on their COTS drone – but they were undeterred.

“That’s how Hecto Drone started as a company. We realised there had to be countless others annoyed by short flight times, and so we started out with classic garage engineering, going from hobby-grade to industry-grade components, and through a huge range of petrol engines, three-phase motors and thermal management strategies, all to create our own hybrid drone generator,” Siggaard explains.

The Hecto Drone generator is now in its seventh generation, having gone from a 4 kW air-cooled first prototype to the present-day 7 kW system that is water-cooled, fuel-injected and weighing 9 kg including all ancillaries.

The system powers Hecto Drone’s two UAV products: the X-8 quadcopter HD-408 and the hexacopter HD-606. Our primary focus here is the HD-606, being the newer, larger and more powerful product, running on two generators connected in series.

The HD-606 was developed over roughly six months, with most of the work being software focused. Hecto largely followed defined laws of physics and mechanics to scale-up propellers, motors and the like from the 408 to the 606, and after a year of beta testing and final optimisations with customers, it was soft-launched for commercial sales in mid-2024. The HD-408 was released in late 2022.

The hexacopter is principally designed for heavy-lifting logistics applications; specifically, flying with slung payloads of up to 50 kg with up to 25 kg of fuel as standard for a 104 kg maximum take-off weight (MTOW). A detailed payload versus endurance curve is publicly available, but as two illustrative samples: a 35 kg payload can be carried for up to two hours, and 24 kg can be flown for 3 hours (with a top speed of up to 72 kph).

The sling-centred approach eliminates the limitations of a fixed cargo bay, and enables quick loading or unloading without the need for wide, open landing spaces or clear weather conditions; hence, the aircraft is especially apt for deliveries to hard-to-reach places.

Fast payload turnarounds are particularly useful for Hecto’s customers, with Siggaard emphasising that customers in need of very heavy lifting logistics UAVs are “the type who very much need to make money.”

To that end, every corner of the HD-606 is designed with cost-effectiveness and long-term reliability at the forefront to ensure that the aircraft functions as an industrial-quality tool that can withstand sorely sub-optimal weather conditions, including wind speeds of up to 15 m/s. It is also designed for certifiability, including compliance with EASA’s MOC2511 standard, which stipulates that a certified UAV in certain missions must be able to terminate its flight in the event of a severe malfunction or similar emergency, and not breach (or allow its debris to breach) the boundaries of a defined acceptable area.

Hecto Drone also has its own full special operations risk assessment (SORA) clearance for carrying out its necessary flights, and it provides consultation and assistance (including key documentation) to any customers seeking their own SORA.

A simple structure

For scalability, Hecto Drone has sought to use highly standardised and widely manufactured carbon parts obtainable from many suppliers. These include round tubes for the rotor arms, landing struts and some internal structural supports, with carbon plates sandwiching foam for an enhanced strength-to-weight ratio in the hub.

“As an example, we don’t use any compound curves because then you’d need a custom mould, you’d need to figure out how to bond it to the next pieces and the supplier would need many iterations to get it right and optimise it – so, simple geometries and well-known part types were the target for us,” Siggaard says.

“And we’re not making a fixed-wing UAV where we need really good aerodynamics. So, sticking to multi-rotors helps us make a cost-effective product that industry can use and can afford to break; because accidents always happen eventually – and our drone is made from parts that can be replaced at short notice.”

Primarily, Hecto sources its carbon composite from X CarbonTech in Bosnia, citing both its product and its service quality. “There was one time our courier really messed up a shipment of carbon plates, right before we had a deadline to deliver some finished UAVs; X CarbonTech worked 24 hours to get a whole new replacement batch to us,” Siggaard says. “It wasn’t their fault whatsoever, but they insisted on helping keep our whole pipeline running.”

Although the HD-606 is configured for slung payloads as standard, mounting plates for directly bolting cargo pallets, gimbals, industrial Lidars or other devices to the undercarriage plate can be (and have been) built to spec.

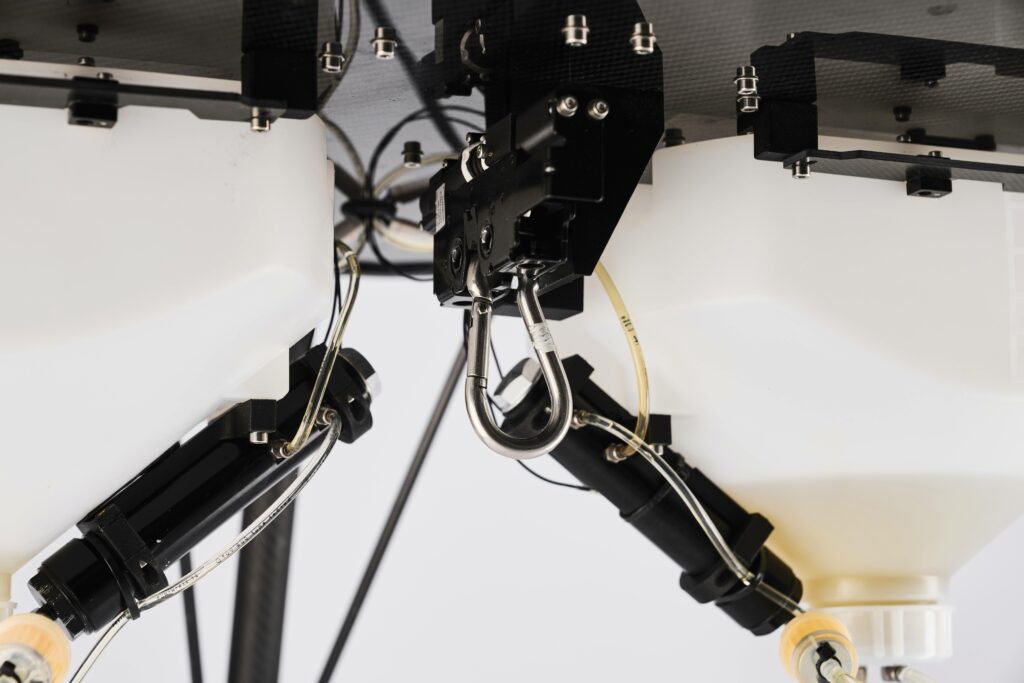

“The drone can carry its full 50 kg payload capacity using a cargo hook we mount underneath – the system we use was originally designed as a security door latch for excavators,” Siggaard says.

“We needed something industrially rated for handling a huge amount of weight, and a constant battery of shock and vibration. Plus, they’re produced in the thousands, so they’re really low-priced and incredibly well-proven tech; we’ve been flying with it for a really long time.”

The device is an 8 mm hook, remotely activated but also with a mechanical override so that it can be toggled manually before and after the UAV is powered (and if power should fail). It mounts to a 90° gusset bracket fastened to the undercarriage with four bolts. Siggaard emphasises that this is not a separate bottom plate but the hub’s carbon sandwich core structure, meaning loads imparted on the slung payload are distributed and dissipated throughout the entire body of the drone.

Engine mods

As mentioned, the team’s first hybrid power experiment involved mounting their standing generator onto a UAV airframe; that was a Honda generator built around a four-stroke, single-cylinder engine, which on top of being too heavy, produced excessive vibrations. Hecto Drone’s ideal generator would have minimal weight and vibration, as well as very high power output – preferably

7 kW or more. It also needed to be able to run non-stop for many hours at a time without needing maintenance checks, refuelling or oil changes too often.

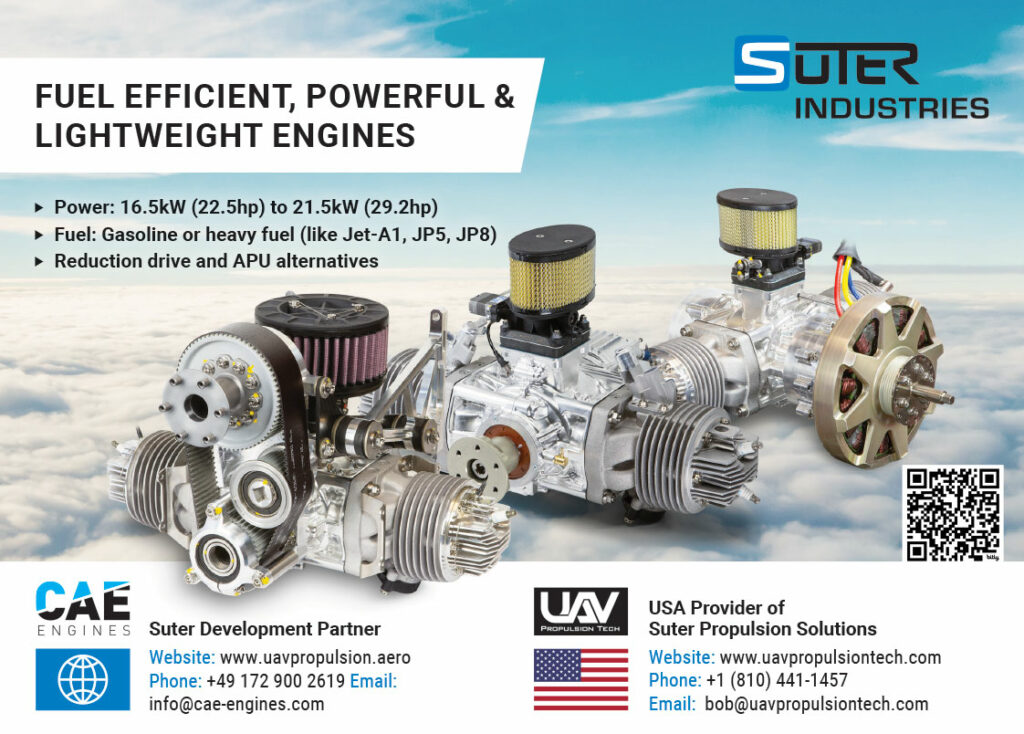

“And then, for viability in commercial services, it needs to be cheap,” Siggaard adds. “We’ve seen some fantastic drone engines in the UK and there’re a few brilliant manufacturers in Germany too. But generally, these products range around £45,000-50,000 in price and our HD-606 needs two of them!”

Hence, using such engines would have made the powertrain cost more than the rest of the drone, and driven up prices beyond Hecto Drone’s target for competitiveness. Instead, the company reasoned that the only engines fulfilling all its criteria are higher-end model aircraft engines.

“Those engines are built in the thousands. So, they’re low-priced and their technology has been around and optimised since the 1960s, meaning that they’re plenty reliable – and if they weren’t, no-one would want to buy them,” Siggaard says.

“They’re also powerful because their customers want to fly fast, and they’re also extremely plug-and-play, given all the different airframes they need to work with; as long as you keep them oiled and within the optimal temperature range, they’ll last a long time, with a 200 hour mean TBO [time between overhauls].”

Exhaustive r&d went into choosing the best engine; hence, Hecto refrains from disclosing their pick to us, but Siggaard notes that it is a two-stroke boxer twin. This architecture minimises vibration because the mirrored motion of each of its opposed pistons cancels much of the other’s first-order vibrations.

“There’re still some second-order vibrations, largely owing to the slight offset between the two cylinders, but at 7000 rpm, it’s really not noticeable. And of course, we mount the engine on rubber isolators so that really damps against any vibrations reaching the rest of the UAV,” he says.

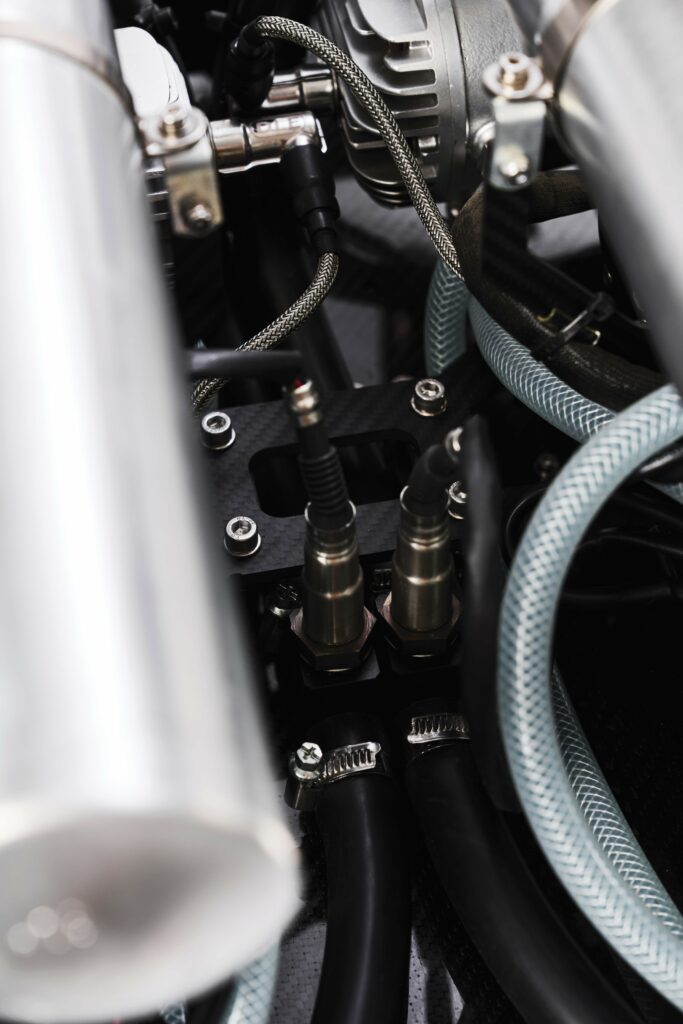

To ensure that the engine stays within the ideal temperature range, Hecto configures it for water cooling (it arrives at their facility as an air-cooled system), which improves both heat dissipation and control over thermal stability in the combustion chamber. To do this, a chamber with an external shell and two fittings is mounted about the cylinders (using industry-standard formulas for designing the shape and volume of the flood chamber), and water–glycol is sent through this using an electric coolant pump.

“We speed the flow rate up or down depending on how much cooling is needed across the power band, and we mount the radiators under the propellers,” Siggaard adds. “So, their downwash cools the liquid and the more load pulled by the motors, the harder the engines work, the more heat they produce, but the more cooling the props produce. It’s a very self-containing loop. We flew last week in 35 C weather and the generators held steady at 70 C or thereabouts.”

additional doughnut tank of up to 66 L may optionally be installed for extended flight endurance

Hecto also integrates bespoke exhaust pipes from Krumscheid Metallwaren in Germany; readers may have noticed their strikingly large mufflers, which are key to reducing noise and hence vibration. The headers are also customised to optimise scavenging from the exhaust ports.

Two 6 L main fuel tanks sit under the hub, one per generator. An additional, dual-chamber doughnut-shaped tank may also be installed, typically at the bottom of the hub encircling the payload attachment point in the middle. The doughnut is rotary-moulded plastic (made by Dan Hill Plast A/S in Denmark, also the producer of the main tanks) and integrates a filtered mid-section such that fuel can be entrenched from one half to another without spreading contaminants.

“The doughnut tank is also scalable. We can fit tank sizes of 22, 44 or 66 L onboard to extend users’ flight times depending on how much payload capacity goes unused,” Siggaard adds. “Gasoline is only 780 g/L, so around 51 kg for up to 66 L extra fuel, meaning very long endurance if you’re only carrying a small package or gimbal.”

Generator management

Hecto Drone’s generator system is controlled via a dedicated generator management unit (GMU), which monitors a wide array of sensor data to precisely govern both shaft horsepower and AC voltage output. To illustrate, the engine’s air and fuel intake are defined within an Alpha-N strategy, meaning crank rpm and throttle position are the primary inputs for throttle or injection changes instead of manifold absolute pressure (MAP) or mass air flow (MAF) – but MAP and MAF sensors are still installed and accounted for in the GMU software.

“Alpha-N is very simple, but running a two-stroke on Alpha-N makes it difficult to optimise operations if ambient temperatures and altitudes are changing dynamically during flight; a basic Alpha-N fuel–air mapping will fall short of edge cases where it’s cold, where you’ve flown up into the mountains, and then maybe the sun appears from behind a cloud or mountain and really heats up the drone,” Siggaard says.

“The two-stroke might then overheat. You need to feed it more fuel, or the mixture will be too lean, produce way too much heat, and risk seizing. We found a lot of problems like that during generator testing, so we had to engineer our GMU to gradually address every one of them, which is why it’s not at all a simple subsystem.”

The GMU largely integrates IP67-rated automotive connectors for long-lasting ruggedness and easy sourcing, the main plug being a large, latching connector with 60 pins. Its associated wires are designed for simple termination and are crimped to their connectors without their insulation (it having been physically removed beforehand) in a highly repeatable, ‘single-click’ process (meaning new assembly technicians need little to no training here).

“We use a Bosch MAF sensor product – that’s the tower you see on top – and it also measures air pressure and humidity, which feed into the GMU, as does a CHT [cylinder head temperature] sensor and another temperature sensor in the coolant channel, just to make sure the engine and cooling system are operating correctly,” Siggaard explains.

An O2 (Lambda) sensor is also installed in the exhaust manifold to correct the GMU mapping tables for any discrepancies between expected oxygen inflows and outflows that might be indicative of combustion irregularities. Altogether, these enable the engine to keep running efficiently with optimal fuel, air and thermal management, even if the drone flies from extremely hot conditions into sub-freezing conditions within the course of a single mission.

“And if a sensor fails, it can still fall back on the basic Alpha-N table, keeping itself alive long enough to return to base, even if running sub-optimally,” Siggaard says. “The extra sensors and connectors add a bit more weight, but you get a better running engine – and a much more reliable and long-lasting drone and pair of generators.”

AC to DC

The rotor of the 7 kW alternator is mounted directly onto the crankshaft, with the stator bolted to the crankcase, keeping the combined engine and alternator assembly within a compact volume.

Naturally, the generator also functions as a motor and brake; thus, Hecto utilised it throughout testing as a de facto dynamometer, thereby saving on the costs and space of an actual dynamometer and dedicated cell.

“In operation, we run the engine at 6500–8000 rpm, and so we matched the rotor’s Kv rating to that, including accounting for what voltage output we’d want at take-off and landing. The higher the load, the more voltage gets drawn down, so the alternator manufacturer needs to know what Kv you need and how many amps you’re running in order to get the stator wire thicknesses and revolutions per winding right,” Siggaard says.

As the alternator spins, it draws a small degree of airflow inward, cooling itself enough to prevent loss of lifespan or loss of magnetisation in the permanent magnets.

“To get DC output for the battery, the alternator’s AC output voltage can be run through a passive rectifier, or an active rectifier if you want more efficiency for a higher price,” Siggaard says. “We chose the passive rectifier for the sake of simplicity – and we mount the rectifier and coolant pump together, saving space and directly keeping the rectifier cool.”

That rectifier–pump assembly, among other generator subsystems, is bolted together using specially chosen lock nuts that do not unscrew under prolonged vibration. Hecto keeps its source under wraps, noting that considerable time was spent selecting and sourcing the nuts. Using adhesives would have been unfeasible because weaker adhesives would rapidly degrade owing to the heat from the rectifier and other electrical or engine components, and stronger adhesives would have made debonding and hence servicing too laborious. Siggaard adds that many other types of lock nuts, such as those with Nylon collars, would have worn out too quickly.

DC power runs into two battery banks connected to the engines via a single high-voltage (HV) bus, meaning that each pack may be swapped while the other remains active, giving a degree of quick hot-swappability. Principally, the bulk of the HD-606’s energy is stored as fuel, but the batteries serve in both electrical buffering and backup energy roles.

“In case the motors or a payload suddenly pull energy exceeding the standard 14 kW net electrical output, the batteries’ collective pool of 10 Ah can cover that for short periods, and thereafter the generators can push to 7.3 kW each to recharge the batteries,” Siggaard says.

“Our general hybrid strategy has the batteries constantly discharging and recharging a little bit, hovering at about 80% SoC to keep them long-lived; staying too close to 100% causes them problems pretty fast.

“If one generator should fail, you can keep flying, maybe just a short while if you’re above 70 kg total fuel and payload capacity, but if both fail, the batteries give around a minute and a half to land at a safe speed and location. We’ve considered putting in a third pack, but it’d cut into payload weight quite a bit, so it’s really up to customers if they want that.”

Measured distribution

The BMS is made in-house to monitor all 24 cells (12 per pack). In addition to managing start-up power to the alternator, and charging and maintenance of the batteries, it tracks for signs of faults. If clear signs of such are detected, it will cut the failing pack from the electrical network to prevent damage to the drone or itself.

It also communicates via CAN with the flight termination system (guaranteed to become a legal requirement for EASA certification) such that if flight termination must happen, a quick and controlled shut down of power to all flight-critical subsystems is performed.

“Downstream from the batteries, we have two HV distribution boxes at the bottom of the drone, built around aluminium busbars with torque-spec nuts, giving a proper industrial configuration optimised for weight and vibration, rather than a hobby-grade mess of wires that could rattle and shear apart after a few hours,” Siggaard says.

While the HV bus upstream and downstream of the batteries is 48 V, two sets of 48 V wires run from the HV distribution system into a central motherboard for flight control and avionics, which has its own further regulators for various device-specific voltages. Doubling up the wires ensures that full voltage power will continue to run into the many low-voltage subsystems in the event of one generator or battery failing, and Hecto uses 4-gauge

(5.189 mm thickness) wires here to ensure that the amperage can be handled.

“The power supplies across the HD-606 can run from 12 V up to 80 V, and we specifically avoid having a cut-off voltage – some UAV manufacturers don’t account for their HV buses having a built-in 36 V cut-off point, and it’s not uncommon for a drone to suddenly lose all power because its bus voltage dipped below that while lifting some heavy weight and pulling extra current,” Siggaard muses.

“It’s really important to think about those dips and edge cases when engineering your power distribution systems because they’re not going to make themselves obvious if all you do is put on a voltmeter for measurements. You at least have to put on a proper oscilloscope to get a full picture of the potential troughs, peaks and failure modes when voltage cycling your drone.”

Power pods

Hecto Drone installs motors, ESCs and 43 in (109.22 cm) diameter propellers as fully integrated, paired packages (with supplier-guaranteed validations and transparent access to product testing data) to ensure robust communication and power transmission between them, with a minimum of vibrational resonances, bonding weaknesses or other mechanical concerns.

“We already spend so much time testing for ideal connectors, nuts, engine components, avionics and so on; we’ve no interest in spending even more hours matching motors to ESCs to propellers, especially when there’re great suppliers across China and Germany who are better at it than we’ll ever be,” Siggaard says.

“We’ve been using T-Motor [or Ligpower] components since 2018, both COTS and custom products they made for us; they’ve been refining their technology for years into essentially the best-quality BLDC motors in the world, and I’ve been to their factory to verify first-hand how they tested and balanced the products they were sending us.

“And we’ve since also started ordering from Hobbywing, who are also really good manufacturers, and a German supplier that we can’t name owing to defence activities on their part.”

He adds that the range of available motors, ESCs and propellers is growing – particularly within Europe – and Hecto Drone thus plans to continue diversifying its portfolio of propulsion system suppliers, especially for the sake of supply chain resilience.

Game ready

As to why the HD-606 uses a motherboard rather than the conventional approach of separately mounted avionics being cabled together, Siggaard explains: “In our first-generation prototype, we bought a flight controller and plugged a GNSS, a companion computer and more into it. Then, we plugged the power supply into each one of those individually, then a dual-redundant comms system had to integrate with each of those, and we added another layer of internal comms on top of that.”

He describes it as having been a “spaghetti monster of wires,” so prone to internal vibrations and shaking, with hobby-grade connectors and cables, that the prototype rarely achieved more than 10 hours’ mean time between failures.

“These days, you get companies like Auterion who make very good, fully integrated flight controller and mission computer solutions, but none of that existed for a reasonable price back in 2018,” he recounts.

“However, all of us at Hecto Drone were used to building our own high-power gaming computers, and at the core of every one of those is a motherboard with dedicated slots for PCI, Ethernet, CPUs, GPUs, wi-fi modules and the like, and very secure, high-speed comms between them – everything a drone needs for control and communication. So, it seemed logical to design our own drone motherboard and, in doing so, achieve the modularity and endless upgradeability of a high-end desktop PC.”

The motherboard is roughly 15 x 15 cm, with a central carrier board for installing a flight computer, making the HD-606 agnostic to its main flight controller (a decision the team made adamantly amid the supply shortages of the COVID years). The system can also be customised for multiple separate flight controller modules if desired.

Power supplies for 3.3, 5 and 12 V are also provided on the board, each port being 10 A and dual-redundant, meaning no single point of failure in power supply, and switching times between a failing port and its still-functioning partner are short enough that no subsystem will boot-down owing to power loss.

“Most motherboard-mounted systems actually consume just 1–2 A, maybe 3 A at most, so the power connectors are really oversized right now; but we know there’ll be drone avionics in future that use more and more power, which we’ll want to use. So, we’ve effectively future-proofed the motherboard design for that,” Siggaard continues.

“We then have two double-size module slots at the top and four single-size slots underneath – an anatomical standard we made ourselves – with a slot for the Jetson Nano at the bottom on a cooling plate with a dedicated fan.”

The module slots typically integrate two GNSS modules – u-blox F9Ps as standard – as well as Hecto Drone’s own breakout boards to extract flight-critical telemetry for performance and maintenance monitoring, with ODU connectors largely used for robust, long-lasting interconnects.

“And if our customers have a special sensor or something with a special interface, we can make a module for them to sit in between for easy compatibility; there’s no need to change the entire electronics stack to accommodate modular requests, and it really minimises the amount of wires going in and out of the board,” Siggaard notes.

The motherboard, as well as all other PCBs in the HD-606, are custom-made by suppliers in Denmark and Germany, with a customised version of the open-source PX4 autopilot software (‘Hecto-PX4’), although Hecto Drone updates its software with every new release of PX4 to ensure that all new features are integrated, and that compatibility with QGroundControl and Mission Planner is maintained.

Navigation and flight termination

Key to the HD-606’s SORA and MOC2511 compliance is a third GNSS module outside the motherboard, integrated for navigation veracity and redundancy.

In general, the company is agnostic to comms, integrating cellular, wi-fi, long-range direct anti-jam radios and other options as needed.

The standard antennas are waterproofed to ensure stable comms during precipitation, and Hecto has previously integrated controlled reception pattern antennas for resilience against GNSS jamming and spoofing for customers. A Starlink antenna and receiver can also be integrated upon request for beyond visual line of sight comms and hence flight termination capacity to be maintained.

“We can install INSs in different places, like near the bottom if an application requires close camera-tracking of the ground – and we tend to be very selective about which INSs we’re willing to use. Without naming any names, we’ve found through masses of testing that even suppliers of very high-priced inertial solutions don’t always live up to expectations,” Siggaard notes.

On the up and up

With the HD-606’s architecture finalised, remaining ‘development’ is limited to short integration work to adapt subsystems requested by customers, such as preferred data links and flight controllers. Some minor ongoing r&d is also inevitable for taking advantage of new technologies (such as batteries or e-propulsion systems) as they come out.

More of the company’s broader focus is on scaling up production at its facility in Aarhus. It continues to widen its supply chain, including bringing in a key secondary supplier of carbon composite from southern England, and it has brought most of its practices and documentation in line with ISO certification standards.

“To that end, my chief engineer and his team have standardised technical manuals for constructing the HD-606 with all permutations of optional subsystems, with clear lists of parts, and QR codes and dedicated shelves for every part and tool, all in a facility kept as clean and tidily organised as possible,” Siggaard muses.

“It’s the same technicians building the drones as before, but this way, everything’s torqued and crimped to spec. It’s so specified, a technician can see how far a screw has unscrewed itself during flight. Moreover, we can quickly and easily train new production staff, and scale our manufacturing output to match customer demand as it grows.”

Key specifications

HD-606

Hexacopter

Hybrid-electric

Two-stroke boxer twin

Gasoline

Water-cooled

MTOW: 104 kg

Dimensions: 2400 x 2400 x 300 mm

Maximum continuous power: 14 kW

Main bus voltage: 48 V

Maximum battery energy capacity: 10,000 mAh (4.8 kWh)

Maximum flight endurance: 8 hours

Maximum speed: 72 kph

Payload capacity: 50 kg

Operating temperatures: -20 to +40 C

Some key suppliers

Motors, ESCs & propellers: Hobbywing, T-Motor

Fuel tanks: Dan Hill Plast A/S

Exhaust components: Krumscheid Metallwaren

Carbon composite parts: X CarbonTech

Connectors: ODU

Payload connector: AMASS

GPU: NVIDIA

GNSS: u-blox

Engine management components: Bosch

Batteries: Panasonic

UPCOMING EVENTS