DSEI 2025

(Image: DSEI)

Time to excel

Uncrewed systems are redefining modern battlefields and military strategies, and countless new innovations from this enormous defence technology exhibition stand to transform both. Rory Jackson investigates

Although vast displays of military tech and its latest advancements abound the world over, Defence and Security Equipment International (DSEI) arguably remains the greatest such show on Earth, with the latest aircraft, ground vehicles, submersibles, ships and robotics of every stripe represented, for armed forces buyers looking to gain critical new tools and tactical advantages in their arsenals.

The 2025 edition of the multi-domain defence technology expo was its largest yet, with more than 1600 exhibitors overflowing from the halls of London’s ExCeL complex, and enormous naval vessels, as ever, moored outside on the Thames for dignitaries to tour.

With uncrewed systems rising in primacy for military strategies globally, DSEI 2025 was rich in new components, vehicles and CONOPS for autonomous vehicles on land, in the air and in the ocean – a selection of which we report on below.

We last featured Schiebel in Issue 57 (Aug/Sep 2024) with a deep-dive into its iconic CAMCOPTER S-100, as well as a brief look at its larger S-300 design. At DSEI 2025, the Austrian OEM officially launched its S-101 and S-301 UAVs as respective updates on those two platforms.

As Lubos Sramek at Schiebel explained, “The S-100 and S-300 established a proven baseline for airborne ISR, mapping and multi-mission operations. Building on that operational maturity, the S-101 and S-301 have been developed as defence-focused platforms – purpose-engineered to host integrated weapon systems – while preserving the flight performance and reliability our customers depend on.”

Examples of such integrations include the S-301’s new sonobuoy launchers for anti-submarine warfare, as well as the ability to launch effector munitions and laser-guided missiles from either craft; the latter requiring additional integration of guidance systems from Schiebel’s partners.

The S-101 has a payload capacity of 50 kg and a maximum endurance of 10 hours, while the S-301 can carry 340 kg or fly for up to 24 hours.

Silvus Technologies spoke with us about its new Spectrum Dominance 2.0 suite of defensive solutions engineered to counter electronic warfare (EW) threats, in particular a software feature called ‘Wake on Wireless’ and its ‘Stealth Mode’.

“Both of these are low probability of detection [LPD] features, which enable a mesh radio to overcome its biggest spectrum-polluting problem, that being the routing beacons for which they need to understand how and where to send data,” said Tom Stringer at Silvus.

“With Wake on Wireless and Stealth Mode, Silvus StreamCaster MANET radios can go RF-silent, where they cease transmitting, and they only receive data packets from other radios which match specified encryption and link distance parameters.”

This capability can allow UAVs to enter an area of operations and start gathering and transmitting sensor or intelligence data silently, until triggered by either a remote ground station or preprogrammed timing or event trigger, thereby delaying detection by local radar, C-UAS or other adversarial countermeasures.

Wake on Wireless, Stealth Mode and other low probability of intercept (LPI) and LPD features are now available across all Silvus StreamCaster MANET radios as a software-licensable extension to Silvus’ MN-MIMO waveform (including the option for prospective users to test, demo or trial the technology).

FT Technologies debuted its FT602, which is a new wind sensor constructed to be both light (170 g total weight) and rugged, not only for uncrewed and autonomous application, but also for yacht racing teams (where it is increasingly popular), and similarly innovation-centred control and monitoring use cases.

“FT wind sensors achieve high accuracy in wind measurements thanks to our unique Acu-Res technology that produces wind data with a much higher signal-to-noise ratio compared to other Time-of-Flight ultrasonics on the market,” explained Chrystal Tan from FT.

“FT’s Acu-Res Technology continues to work reliably in rain and is shock-resistant, as with our products being IP67-rated and EMC-tested.”

The principal difference between the FT602 and the FT7 range of sensors from FT Technologies is the use of injection-moulded plastic for the sensor enclosure, rather than aluminium; this enabled FT’s engineers to save weight and enhance the performance of the device.

Engineering for this meant dealing with different design considerations and the tolerances of injection-moulded plastics over traditional machining methods. Additionally, ensuring that sensor performance was stable throughout different environmental situations meant that material selection was a key part of the product development.

By extension, that meant repeated exhaustive environmental testing was undertaken to prove the reliability and robustness of the new sensor – all validated through external test houses.

The FT602 measures wind over 360° and with speeds of up to 75 m/s (270 kph). It is a low-power (5 V) device that interfaces via a robust connector with industry standard comms such as NMEA 2000 and NMEA 0183 over UART, RS485, RS422 and CAN bus as of writing.

LEMO unveiled its new OPTIMA D series of compact and miniature push–pull connectors engineered for military and harsh-environment applications. These connectors are IP68-rated, even when unmated, and fully tested to Mil-Std 810H standards and feature a patented latching ring that enables the push–pull capability as well as breakaway versions for emergency disconnection.

“We also reduce the connector length by about 25% over original LEMO connectors by way of an overmoulding design on the back. LEMO also provides cable assembly, flex-PCB wire design and soldering services as part of its integrated supply partnerships,” said Fabien Autret from LEMO.

The OPTIMA D connectors come in five different sizes and three different outer-shell models, enabling various configurations including multipole, high-speed (USB 2.0 nett warrior protocol compatible, USB 3.2 up to 10 Gb/s or Ethernet) and coaxial configuration.

“Our connector is principally made from brass, offering great robustness, even more so than aluminium – then it is nickel plated for added corrosion resistance, as well as reducing the amount of shine it gives off, meaning better stealth properties for users working in special forces and similar military branches,” Autret added.

Nokia unveiled its Banshee 5G tactical radio, which is designed as a core part of the Finnish company’s support for mission-critical battlefield networks.

“The Banshee tactical radio is effectively a portable, pack-carried 4G/5G radio developed as part of the new wave of battlefield-of-digital-things, of which uncrewed systems are set to be a key part, including aerial, terrestrial and maritime drones that need to be monitored and controlled by soldier teams on the ground,” Nokia’s Arnaud Legrand told us.

“Achieving high-fidelity remote monitoring and control requires a high-capability cellular network, especially for HD full motion video or 360° video for troops and their mobile command and control centre. The Banshee tactical radios, tactical communications solution and their 5G technology are critical to that capability and the scalability that’s needed for it too.”

The Banshee 5G tactical radio measures 340 mm wide, 444 mm tall and 120 mm long, while weighing 11 kg including batteries. It provides a 5G ‘bubble’ of up to 1 km maximum effective radius over 5G bands n77/78 (3.5–3.9 GHz), as well as integrating comms for MANET mesh radio over L-, S- and some C-band frequencies, on top of also functioning with LTE over bands 1/3/7 and CBRS (700–3700 MHz).

“It also integrates an edge computing platform for running applications locally, and can support up to 128 end-user devices, be they handheld solutions, uncrewed vehicles, crewed vehicle radios or so forth,” Legrand noted.

Gladiator Technologies showed us some fully hermetically sealed versions of standard products from its portfolio of MEMS navigation solutions.

“To start with, that’s meant taking our Landmark 005 IMU and G300D triaxial gyroscope, and putting them in hermetic stainless-steel enclosures; those hermetically sealed IMUs and 3-axis gyros have since been tested and qualified in some low-Earth orbit applications, as well as some other applications that benefit from that level of sealing,” said Gladiator’s Eric Yates.

Both solutions incur a marginal weight increase from the extra sealing, keeping SWaP generally the same as before. In return, the environmental tolerances of the navigation components are greatly improved; in the context of space vehicles, for instance, the hermetic sealing keeps the IMU and gyro safe against otherwise deeply harmful hazards such as the helium backfills often present in spacecraft for leak detection.

“Sealing in this way can be difficult or expensive because it presents extra manufacturing steps such as precise weldings, and different materials to the standard aluminium have to be utilised, but it makes our enclosures much more environmentally secure, and we’ve managed to figure out how to do it cost-effectively,” Yates added.

“So now, we’ve got other products to hermeticise on our roadmap, and we’ll likely offer hermetic sealing as a standard optional offering alongside new releases in the future, except in cases like our open-loop accelerometer chip, which is already hermetically sealed at the chip level.”

PWR, an AS9100- and NADCAP-certified name in thermal management technologies, showed us a ruggedised electronics cooling system, designed and built for compatibility with the VITA 48.4 standard on OpenVPX systems (regarding mechanical interfacing for liquid-cooled plug-in modules).

“More clients are experiencing high electronics thermal load from a stack of CPUs, GPUs and other AI-processing systems for airborne platforms, which is driving the need for liquid-cooling assemblies like this one, instead of traditional conduction- or convection-cooled products,” said Andi Scott at PWR.

PWR can manufacture such supercomputer housings (complete with liquid flow channels and interfaces) in 6U or 3U formats, while working with customers to match geometries for desired computers’ or boards’ dimensions, as well as their typical hotspots or thermal loading patterns, such that the internal components can be consistently cooled in as small a form factor as possible.

“Manufacturing a 6U thermal management housing with liquid flow through cold plates requires engagement with customers at the concept level, supporting them with intensive calculations and simulations to predict heat loads, and then prototyping and iterating their eventual product in a vertically integrated facility,” Scott continued.

“That facility enables us to control all processes that can go into our products, including vacuum brazing, additive manufacturing, CNC machining and various surface treatments. But more importantly, we consult on design to avoid critical issues like poor flow distribution among electronics cards, derating of embedded systems and inefficiencies in cooling. We simulate those with CFD software, which we hone specifically for heat transfer to meet our customers’ needs.”

Sierra-Olympia Technologies is enhancing its product portfolio to include the increasingly popular Mobile Industry Processor Interface (MIPI) standard across many of the thermal cameras it produces.

“MIPI is the most common direct-to-processor interface right now: most processors ingest digital video via MIPI-CSI2, and all of our customers want to get our camera data in thermal video format directly into their processors,” said Chris Johnston of Sierra-Olympia.

“That’s entailed devoting most of our engineering bandwidth towards adapting most of our cameras with feature boards to comport with various MIPI interfaces, mostly with the NVIDIA processors, particularly the Jetsons, Orins and Xaviers right now.”

While the MIPI standard is robust (no small contributor to its popularity), its hardware layer lacks uniformity across sensors and processors – some will have 22 pins, others will have 26 and different permutations will have the pins laid out in differing orders. Hence, the Oregon-based company is continuously engaged in close partnership with its customers on unique solutions for each MIPI implementation.

Many such implementations are common and repeated, while others require special attention and customisation; consistent among all of them is dependable support from the first contact point with a MIPI customer, with Sierra-Olympia’s engineering staff regularly interacting with end-users and -implementors to ensure their success with MIPI camera integration.

Reventec showed us a new ultrasonic fuel flow sensor, which has been miniaturised into a package suited for high-end class 1, 2 & 3 UAV requirements. Originally developed by its sibling company Sentronics for motorsport applications, the system has been reconfigured internally by Reventec for a standard-issue weight of 96 g.

“As far as we’re aware, the RealFlow d series is the lightest precision ultrasonic flow sensor anywhere on the market – and owing to its ultrasonic tech, there’re no moving parts within its design,” said Neville Meech at Reventec.

“Most traditional flow sensors use a mechanical system, such as an impeller that rotates as fluid flows through it; the sensor electronics count the impeller’s revolutions and, as a result, interpolate flow. Small engines however, like single- or dual-cylinder UAV engines, can have really low flow rates, practically a couple of teaspoons per minute.”

Such flow rates are extremely difficult to measure accurately with a mechanical sensor because the fluid inertia is often insufficient to cause the impeller to rotate. In the RealFlow d series, time-of-flight (TOF) measurements are instead conducted via a pair of ceramic transducers.

Each transducer is excited with an electrical signal, creating an ultrasonic pulse either up or down the flow tube, which the opposing transducer receives, with the difference in latency between the two defining the velocity and hence flow rate of fluids passing through.

“We’ve had a UAV customer come in this morning, who’s using a mechanical flow sensor with their single cylinder engine – they’ve been having endless calibration issues, exacerbated because it’s a multi-fuel engine, and each fuel has a different viscosity, translating to a different inertia effect on the sensor’s impeller,” Meech added.

“That recalibration takes up huge amounts of their time but, with our digital device, we can store multi-fuel calibrations within the flow meter, to potentially eliminate that problem and offer operators greater flexibility.”

While ultrasonics are slightly more expensive than mechanical flow sensors, their enhanced accuracy will enable UAV operators to optimise their fuel usage and allow them to maximise their mission strategy.

Certain aspects of the sensor are customisable, such as the hose connections. A standard barb fitting can be switched to a threaded fitting of various sizes if preferred. Its standard electrical connector may also be interchanged for several alternatives or a customer’s preference. Reventec estimates total weight may vary by up to ±5 g following customisations.

As of writing, the sensor is being qualified to an exhaustive list of military standards, all of which are anticipated to have been granted by close of 2025.

Echodyne unveiled its new EchoShield Rapid Deployment Kit (RDK). When built, the system consists outwardly of a tripod-mounted radar assembly, with that assembly comprising four of the company’s EchoShield radars together with key supporting componentry enabling the radars to be fully operational in any domain.

“The idea of the RDK is to provide an entire kit that provides a small squad, when they arrive in a new area, a quickly deployable, 360° hemispherical coverage for near-instant situational awareness,” explained Leo McCloskey.

“Within one hour, two people can set up the RDK. That’s achieved through it being made from just a few parts: the tripod base piece, a mast that screws into the tripod, some arms that screw into the mast, and the radars that slot into the arms and plug into a junction box. Lastly, the junction box pops out a power cable and an Ethernet line for a power source and C2 interface.”

In addition to requiring minimal set-up before troops’ own UAVs and potential enemy UAVs can be radar-tracked, the RDK collapses into three Pelican-type containers (including the power supply) for portability.

Manta Air showed us some of its latest work in customised parachutes for UAV applications. One example it displayed on its stand was built into a small Pelican case, to demonstrate how its solutions can be deployed in COTS or specific payload containers.

“To develop this system, we went through a lot of tests and iterations, which validated that its parachute would deploy quickly, and achieve repeatedly precise landings for any rotary or fixed-wing UAV carrying it, or for any cargo payload dropped by UAV,” said Denis Grab of Manta Air.

The company uses a combination of drones and cranes to test its parachutes in-house; the former being utilised for up to 50 kg systems, and the latter for heavier weights, including uncrewed aircraft weighing up to 1000 kg.

Exail launched its first-ever UAV-specific IMU, the UMiX-40. The system integrates fibre-optic gyros (FOGs) and quartz accelerometers to achieve north-seeking capability and stable navigation data, particularly for UAV missions to continue unaffected during GNSS jamming or spoofing.

“Development started in 2017, with production and commercialisation starting three years ago; we miniaturised the FOGs, the accelerometers, the electronics box and the mechanical assemblies from our previous systems to target 10 times the overall performance of systems of competing size,” said Sebastien Ferrand at Exail. “For instance, composite bias drift is usually 1°/hr in most IMUs; with UMiX-40, it’s below 0.1°/hr.”

All components were manufactured in-house at Exail, including fabricating the quartz accel chip design shrunken-down to one-third that of the French OEM’s first-generation chip. For UAV integrators, the IMU can be mounted with fasteners from the top or bottom of its housing, with a single power and data connector for interfacing.

UMiX-40 is also available in both military and civilian versions, the former being heavier-duty in performance. For instance, the former’s gyroscopes have up to ±2000°/s dynamic range, and its accelerometers ±100 gs of dynamic range, while the latter’s gyros are up to ±490°/s dynamic range, with its accels having up to ±30 gs range.

MKS Servos was on hand to discuss some of its newest rotary actuator products, particularly those that have been redesigned to function on 24 V power inputs, up from the company’s traditional product line of 12 V servos.

“Many customers requested this higher voltage to reduce current throughput, which means they can use thinner wires which weigh less, being very important for drone applications,” said Max Wang at MKS.

“Reducing current also reduces EMI, meaning the UAVs don’t need such rugged EMC, and there’s less noise interfering with onboard data links or sensors. So higher voltage is useful all around.”

The primary engineering challenge for MKS was fitting larger, higher-voltage componentry (such as connectors and ESCs) into the same small servo housings as used previously in order to provide the new 24 V systems as drop-in replacements for their older 12 V counterparts.

Resolving this required putting significant design rigour into new PCBs for those servos, such that the new high-voltage parts could fit alongside the same integrated circuits, capacitors, gearboxes and bolts as before.

One example of the new 24 V systems is the company’s Z2200-24V, which matches the older Z2200-12V’s 95 g weight and rated torque of 2.45 Nm, but has a 1.2 A rated current (to the 12 V servo’s 1.5 A) and 6.8 A max stall current (to the 12 V servo’s 10.5 A). It is also faster, with a no load speed of 454°/s (while that of the Z2200-12V version is 368°/s), and the same operating temperature range of -40 to +70 C.

Also available now is its P500-24V, a 133.5 g servo rated to 1.47 Nm of torque, 600°/s no load speed and 1.5 A rated current, alongside the also-new Z1500-24V, which is a 38 g servo rated to 0.58 Nm of torque, 375°/s no load speed and 0.35 A rated current.

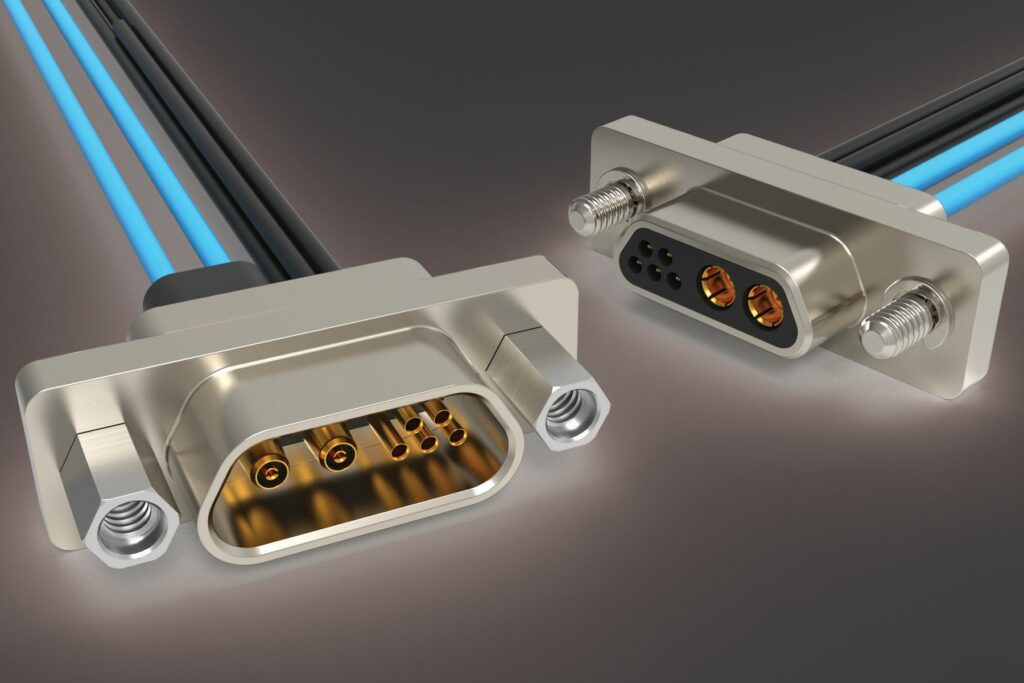

Omnetics showed us a new shielded, parallel-pair wired connector, which is built using its standard nano-D systems but engineered to better maintain dielectric properties between its lanes.

“What this effectively demonstrates is high speed; we’ve published a catalogue documenting all testing reports and performance charts on this solution, showing that it achieves a 20 Gb/s data rate at cable lengths of 6 in [15.24 cm],” explained Travis Neumann at Omnetics.

The company also showcased a new NanoRF contact compliant with VITA 67.3 standards, which uses a micro-D connector housing and the RF contacts can be combined with micro contacts for a hybrid configuration for sub-miniature push-on micro (SMPM) contact applications.

“Those came from a partnership with Teledyne Storm Microwave, and provide a really great packaging; now we’re hybridising them for transmission of differing data and power links to suit the tendency towards hybrid connections in uncrewed applications,” Neumann continued.

The VITA 67.3 NanoRF has a characteristic impedance of 50 Ω, an operating frequency of up to 40 GHz, and isolates against channel-to-channel crosstalk of at least 90 dB across varying operations and environments.

Along with expanding its high-speed connector offerings, “We’ve also invested in really good equipment this year for laser stripping of magnet wire, which we demonstrated with a wired polarised Nano connector earlier this year,” Neumann added.

“That featured 32-gauge wire, and our standard Teflon insulation and an enamel coating around a niobium-titanium wire. That kind of solution is ideal for space applications, cryogenics and even medical – anything where SWaP really matters.”

Sightline Intelligence’s new AI target recognition (AiTR) feature has been released. The feature has been field-proven and integrates deep learning technology into the company’s well-established, low-SWaP video processing and target analytics algorithms. The company (formerly known as Sightline Applications) is best known for its technologies developed for improving situational awareness across aerial, terrestrial and maritime uncrewed systems.

“With this new feature, we recognise and classify multiple decision-critical attributes of targets simultaneously: for instance, the bounding box we form around people will annotate whether they’re armed, or if their pose indicates that they’re surrendering, or if they seem to be wearing combat gear,” said Rahul Kota of Sightline Intelligence.

Kota emphasised that the company’s approach prioritises reliability and interpretability over hype. “It’s an edge-level feature, so we can’t tell users exactly what to do – AI technology itself hasn’t advanced far enough yet, as much as some AI companies overpromise and underdeliver – but we’ve put immense work and rigour into making AiTR as trustworthy and reliable as possible for target analytics solutions.”

As well as focusing on high-quality data, the team behind the new target recognition feature practices “machine learning safety techniques,” including rigorous data assurance processes aimed at maximising the chances of its algorithms working as consistently in the real world as in the lab, even amid severe precipitation and occlusions or very poor camera angles.

“We also do things like multitask learning to exploit shared features that can be learned in the backbone – that’s key to how we achieve that multi-attribute classification – and we also modularise to get benefits like two-stage networks,” Kota added.

“Those are composed of one object detector, followed by a classification network after it, allowing us to deal with both strange, new objects and poor imagery lacking in pixels by continuing to work consistently and reliably.”

Octane Wireless exhibited a number of new antenna offerings designed to maximise compatibility with new radio products improved and released over the past few years.

“Our most popular products are our UAV blade antennas, which are lightweight, aerodynamic antennas for fixed-wing aircraft, available from 800 MHz to 6 GHz, but VTOL UAVs are really where we’ve been expanding our offerings to catch up with new radios,” explained Austin Farnham of Octane Wireless.

“The stub-type antennas have proven very effective, partially due to being lightweight and also covering 315 MHz all the way up to 10 GHz. They’re electrically small antennas, housed in a ‘stub’ about the size of a finger.”

The company also now supplies MANET antennas suitable for mesh networks, connecting not only VTOL and other UAVs to such radio environments but GCSs also.

Flare Bright showcased two new systems for GNSS-denied or -free navigation. The first was Tactera, a terrain-referencing navigation system expected to enable 10 m accuracy.

“As a given UAV flies over undulating terrain, Tactera combines ground elevation readings from a very small, automotive-grade laser altimeter, with information from Lidar-based digital surface maps – which are freely available for most of the UK and continental Europe – to localise where the UAV is,” said Matt Starkey at Flare Bright.

The second solution was Intera; a software-only system that boosts the INS performance of a UAV, requiring only pre-existing, already onboard system information in combination with a digital twin (DT).

“The general way it works is that we create a DT of your aircraft, giving a very close sense of how it should fly through the air,” Starkey continued.

“This DT is then embedded into Intera and, using existing data such as that from inertial sensors and actuator inputs, can limit the bounds of errors typical of an INS, which normally result in quadratic or exponential growth in navigation error.”

Hence, Flare Bright ‘linearises’ those effects by bounding those errors with its DT-based methods. The core technology was originally developed for its Snapshot drone because that system was so small it could not fit a GNSS receiver or antenna, and therefore needed a means for navigation without GNSS.

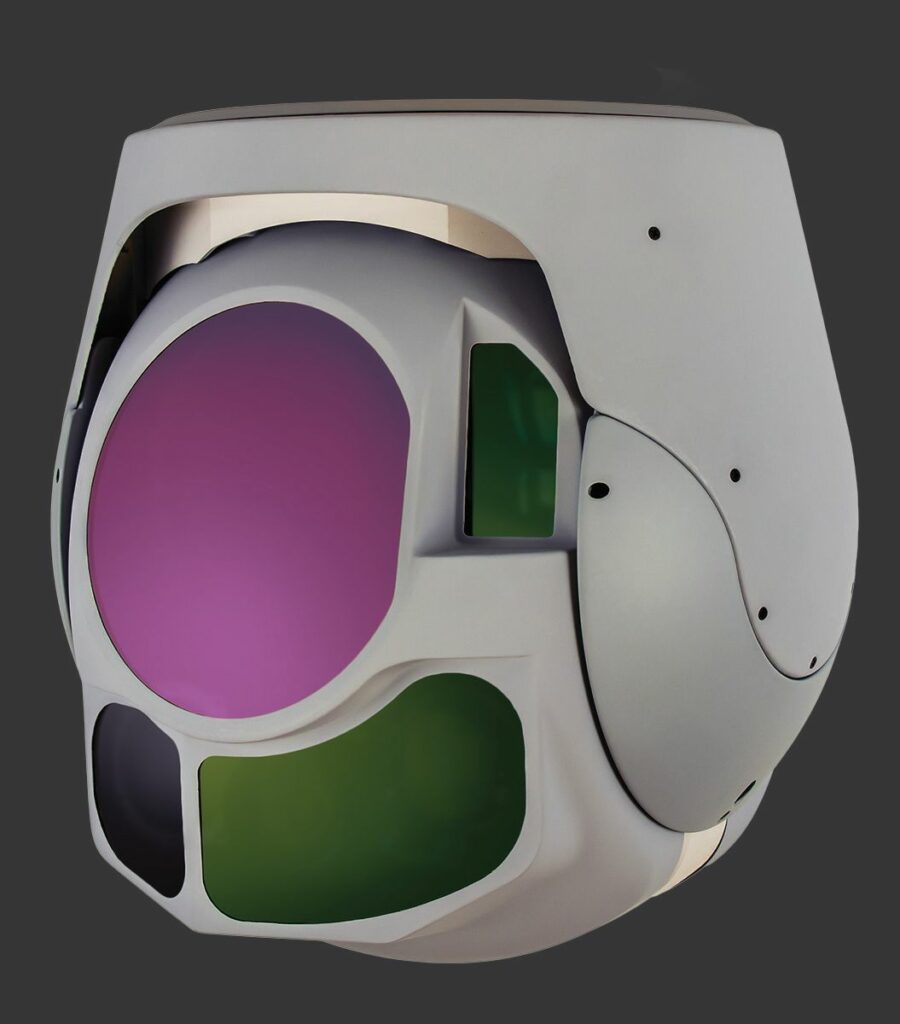

Hood Tech Vision showcased a number of its newest camera gimbal systems. First among those that the company discussed with us was its 11EOIR6-HD, the heaviest-duty of its ALTICAM 11 product range.

“We’ve been designing and manufacturing 10 in [25.4 cm] gimbals for about a decade and a half now, and the 11EOIR6-HD builds on that success and key projects over that timeframe like the RQ-21 Blackjack,” said Nolan Ohmart from Hood Tech Vision.

“New with this gimbal is a significantly enlarged MWIR lens, which results in crystal-clear, HD, MWIR imagery. We’ve upsized the EO optic as well, with engineering focusing on fitting these large lenses in places other companies might struggle with.

“To do that, we have an optics scientist in-house, whom we believe to be one of the leaders in the discipline. They’re key to achieving our own optics designs and thus our competitive edge, as are our strategic partner suppliers who help realise those designs.”

The company also showed us its 06EO, the optics and sensor core of which were designed entirely in-house, meaning its form factor could be tightly integrated to optimise performance within the constraints of its 5.8 in (14.7 cm) diameter and 2020 g weight.

“But especially new at this show is the 06EOIR3, which brings our latest laser designator capability: the size of the designator is significantly increased over that in the preceding 06EOIR1, enabling greater standoff ranges for any munitions precision-guided by the gimbal’s laser,” Ohmart says.

“We’ve also added an SWIR imager, enabled by custom optics, which sits alongside the MWIR and can actually visualise the laser light for precise targeting.”

Following Connect Tech’s unveiling of its Gauntlet carrier board earlier this year, the company is now embarking on its next steps for Gauntlet’s development and diversification roadmap.

“We were effectively first-to-market with a carrier design suitable for land, air and sea, and capable of harnessing the NVIDIA Thor, but still rapidly deployable rather than just being a dev kit – so, what’s coming next is a lot of variants on the Gauntlet,” Jonathan Malaney from Connect Tech told us.

These variations come as part of the company’s standard development roadmap, but are also extensively influenced by customer feedback from the past several months. They are to include miniaturised versions, enclosed versions (with application-specific combinations of environmental protection and thermal management systems) and versions embedded with AI software that Connect Tech is developing.

The latter will include taking large ‘recipes’ of models and running them at the edge on smaller devices – that is, installing them on SWaP-optimised devices to achieve an entirely localised edge processing without the vulnerabilities of an internet or cloud connection.

“That could be on a Thor, but we can also still work with the Orin and other legacy platforms to match the degree of processing potential each customer use-case needs,” Malaney continued.

“And we can put that in an open board, or one of our VPX systems, or one of our server boxes; whatever software, sensor integration or so forth that customer is doing, we have a COTS answer for it – and we expect the first of the new Gauntlet variations to be ready for customer testing by January 2026.”

UPCOMING EVENTS