Composites

(Image courtesy of Hoverfly)

Stronger together

Surging demand – particularly from defence – is pushing the composite world hard, which is responding with expert finesse and some crucial innovations. Rory Jackson reports

The world of composites, much like the rest of the world, is undergoing particular upheaval with respect to its relationship with uncrewed systems. Conflicts around the planet have awoken defence forces everywhere to the revolutionary power of fleets of small, rapidly manufacturable and fast-deployable drones in the air, on land and at sea.

As a result, uncrewed systems markets are booming at unprecedented rates, meaning grants and contracts for composite part manufacturers have gone through the roof. Here, one might assume that cheap, low-quality parts were becoming all the rage, especially because so many now seem to be constructing kamikaze or attritable drones.

However, upon closer inspection, the expense of high-quality avionics and intelligence means that high-end composite products, designed by manufacturers with care and expertise, are still very much the name of the game. Whether reusable or made for one trip only, uncrewed systems are purpose-built, with serious, strategic consequences ensuing from their success or failure – and because composites almost universally form the protective and structural tissues of a drone’s body, a drone made from poor-quality or misspecified composite parts will fail to fulfil its purpose.

Hence, composite manufacturers are honing their best practices, adopting new materials, and innovating new design and production approaches to keep up with the pace of new advancements and trends in the uncrewed space – among which is a noteworthy push for weight efficiency.

Weight matters

To state that uncrewed systems manufacturers are trying to cut product weight wherever possible might sound like rehashing old or perennial news. However, composite manufacturers today are emphatic that there has been sizable demand growth for especially lightweight materials. Standout among them are woven unidirectional-fibre materials such as spread tow cloths, which are amid the more expensive carbon fibre variants – but they are also thinner and lighter than other widely available fabrics such as plain weave or 2×2 twill.

(Image courtesy of Decavo)

Other, newer materials are also available, which stand to offer greater strength and resilience in how they withstand or distribute loads (be they mechanical, thermal or so on). But reportedly, until those materials become cheaper (for instance, through advancements in their underlying technology and manufacturing rates ramping up), their superior material properties are not yet justifying the weight penalty they stand to impose.

With uncrewed vehicle manufacturing being so heavily price- and weight-driven, thinner weaves of carbon have naturally risen in popularity. Additionally, in catering to the aforementioned boom in small UAVs and other uncrewed systems, a problem has arisen in that carbon fibre cloth comes with strictly required minimum order quantities – and for companies making small parts and small drones, in not-necessarily large batches, the pain of wasted leftover material lying on the cutting table becomes grievously familiar.

Design trends

While the uncrewed world is distinguished by customised, requested variations on offered products, designed to spec, and typically ordered and manufactured in small volumes compared with other industries, composite part manufacturers distinguish themselves through improvements – ranging from minor optimisations to vehicle-saving corrections – in the design of user-submitted part requests.

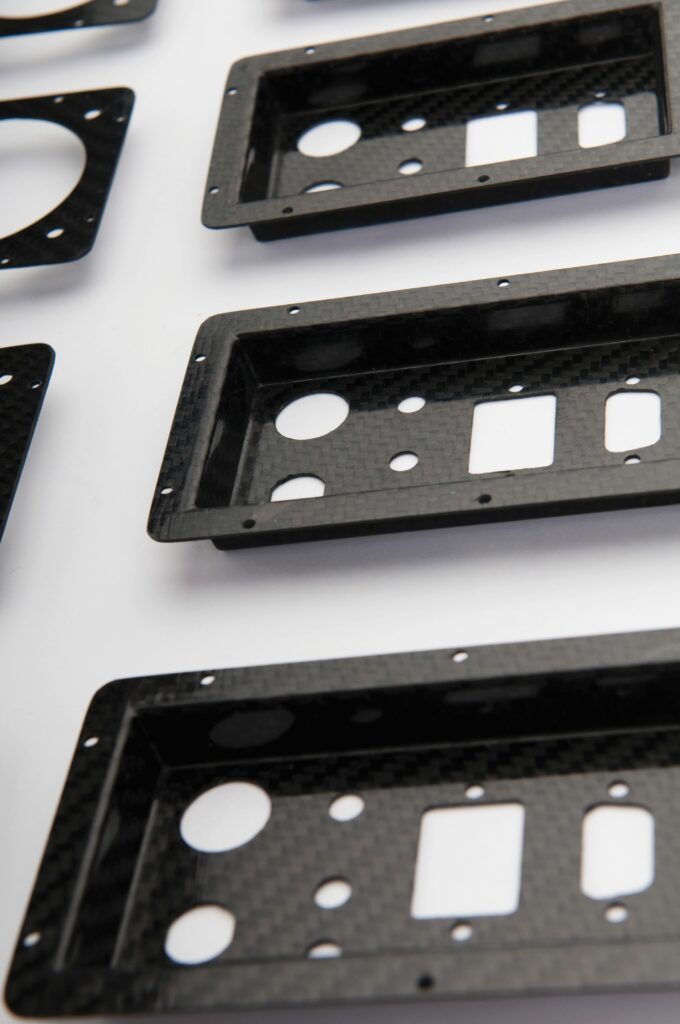

Most of these corrections are geometric in nature, with a great many arising as customers seek to switch certain parts from metal to composite materials. For example, metal enclosures, fairings, spars and so on naturally come with sharper corners and edges than composite can be easily supplied with, given that ductile metals can be formed and bent flexibly, whereas carbon fabric is reluctant to fold or crease (like a piece of paper will) when cured.

In such instances, some geometric reworking or finessing on the composite manufacturer’s part is key to helping the carbon lay in and conform to the desired shape. Cutting and overlapping ply in key areas, or use of specialised, hardened tooling to increase pressure in the interior surfaces of a part pre-curing, for example, can be carefully carried out as long as the composite engineer maintains a feel for where to cut and lay fibre such that no excess strength is lost (because a joint is always structurally stronger with continuous fibres running through it, than with two cut, separated fibres being bonded edge-to-edge).

(Image courtesy of Real Carbon)

Modelling for such potential improvements to parts via software is not easily pulled off. Most CAD software tools for modelling carbon fibre components are building a reputation in the higher-end composite manufacturing community for showing deformations in a part, or otherwise claiming to the user through simulations or 1D calculations that what they want simply cannot be achieved – despite many of these simulated failures being, in reality, perfectly viable, constructable and reliable over an acceptable service life.

This is particularly true of complex and hard-used componentry. Gimbal housings may be the foremost example of something challenging to engineer and manufacture well using composite materials – effectively being the composite equivalent of turbine wheels in the CNC metal machining space (see our Machine Tools Focus in Issue 63).

Gimbal housings have become smaller and smaller over the previous 10 years, as drones (and other uncrewed vehicles) become more professional and viable for gathering mission- or market-critical data. Their internals are made onerously complicated by high concentrations of mounting points, wire routing features, recesses for lenses, sealing surfaces and more. They must additionally be designed to mitigate vibration, severe internal heat, dust, humidity and other environmental hazards, given that they hold enough sensitive electronics to typically form the most expensive component on any vehicle. Hence, it takes highly specialised software to model all of this, and to determine how its composite parts might be formed and assembled.

Most CAD software aimed at composite parts, however, is not engineered for accurately representing the small, complex geometries typical of the uncrewed industry. Instead, most such tools are made for large-scale, large-sized aerostructures.

Hence, as frustrating as it may be for vehicle manufacturers hoping to train and hone all necessary carbon fibre design expertise in-house, more and more high-end composite part suppliers avoid reliance on software and instead go by their own internal expertise – built up from lessons learned and expert feel for how different fabrics, resins, moulds and heat levels will affect one another when combined.

Materials diversity

As indicated, weight reduction is a veritably universal concern among system manufacturers, and thus some composite manufacturers will aim to simulate or redesign requested structural fairings or subsystem housings in a variety of material combinations more lightweight than that in the received CAD file – as long as they are certain that the part need not endure any very harsh conditions or manoeuvres.

For such weight-sensitive applications, a number of aramid-type matrix materials like Kevlar and Nylon have grown in popularity, with both glass and carbon fibres running through. The former is especially gaining traction as a radio frequency (RF)-transparent material – this property making it harder to detect in military theatres and more capable of permitting critical radio transmissions through (unlike most carbon composites). Composite manufacturers have become especially proficient at curing carbon and glass composites together seamlessly, such that the aerodynamics are preserved and that the placement of radomes and comms systems is made challenging for hostile observers to discern.

Among particularly weight-sensitive airframes, one might also find fibreglass composites being used for wings, fins, nose cones and fuselages, with concentrations of thinner carbons used in structurally loaded areas such as wing roots, and aramids selected for leading edges for optimised ratios of impact resistance versus weight.

When manufacturing the lighter materials, prepregs are often used preferentially, especially given that they are supplied with consistent distributions of resin and fibre. This ensures that every finished part has the same weight and distribution thereof, with no real chance of excess material and weight making its way into any section of the final part. It is also inherently easier to train technicians to work with prepregs than to impregnate dry cloths or mats of fibre by hand, which filters into lower per-unit and -batch costs.

For heavier-duty operations, carbon-fibre-reinforced resins remain the foremost choice, with thicker weaves and higher grades of fibre in excess of 200–300 g/m2 being common. Such materials are still largely indispensable when having to deal with highly aerobatic manoeuvres, turbulent conditions and potentially repeated hard landings.

A wide variety of foam core materials remains available, with Rohacell still being a top pick in wing sandwich panels for its very high strength-to-weight and very low weight-to-volume (around 15 g/L median weight-to-volume ratio among the grades available), although PVC and expandable polystyrene are also popular for similar reasons.

And while spread tow has seen growing mainstream uptake in recent years, despite being hard to work with because of the thinness of its fibres, it is also building a niche as a more aesthetically pleasing alternative to other carbons. In the increasingly mature UAV market, manufacturers are growing more determined to make their aircraft stand out, and resemble something that professional fleet operators would actually want to be seen flying and working with – hence, the importance of material attractiveness is no longer something to be ignored.

Interestingly, some types of biocomposites are reaching commercial viability, enabling a considerably more sustainable lower-carbon option than most other composites, for those who take interest in such matters. Among the most eco-friendly of these is a solution that uses widely grown flax (or linseed)-based fibres to reinforce matrices made from furanic (or furan-based) resins, the latter being typically derived from agricultural by-products.

This type of material, which is suitable for wings, fairings and other aerodynamic components (as well as some structural parts), comes with an aesthetically pleasing finish, and can form entirely biological components (adhesives for part bonding and additives for printing notwithstanding). As of writing, the necessary material inputs are harvested extensively across Belgium, France and the Netherlands – but the present cost-per-unit is somewhat hampered owing to the weather-sensitive nature of the source crops, which then affects the ability to produce it in volumes (and by extension, prices) matching those of carbon composite. The lengths of the fibres are also often limited to the lengths of the plants (which typically grow to heights of 80–120 cm), but manufacturing quality has rapidly improved to compensate for this.

Hardier options are on the way, fortunately. Among the most promising are hemp-based fibres; hemp being a highly resilient and profitable crop that can be grown in a wide array of climates and locations. It also frequently comes in longer strands than flax, often enabling thicker, stronger weaves and panels.

(Image courtesy of Scabro Innovations)

Military users might not automatically care so much – outside of certain armed forces committing themselves to carbon reduction out of a recognition that mitigating climate change is a strategic imperative – but they would benefit from giving renewable composites a second look. Flax fibre, for instance, is surprisingly strong relative to its weight, its fibre lengths are highly consistent (hence, its applicability for potentially very reliable structural parts) and it is touted to exhibit high vibration-dampening properties.

Obviously, this is ideal for reducing maintenance- and repair-related costs, while also being vital to keeping intelligence, surveillance and reconnaissance imagery clear and free from blurring or shaking. Moreover, modern military forces are increasingly adept at detecting vibratory sound waves through the air, to the point that certain drones can be recognised and even broadly localised with approximate velocity from up to 400 km away. If, however, a drone were to be built from flax fibre composite, or if some carbon body panels were swapped with flax ones, the vibratory signature of the UAV could be changed or reduced enough to prevent such tracking and detection.

Additive manufacturing

It bears mentioning also, alongside the mature, tried and tested production approaches for conventional composite systems, that additive composite manufacturing has achieved great strides in recent years, advancing beyond mere rapid prototyping jobs into batch and series production of field-deployable vehicle parts.

The selective laser sintering (SLS) process, for instance, has undergone substantial improvements in its precision, layer resolution and surface quality, enabling shorter production cycles, closer dimensional control and the production of complex part geometries with minimal post-processing work.

Material formulae for printable composites have also been optimised for various purposes. For instance, one lightweight printed carbon composite has been pared down to a weight density of 0.87 g/cc; notably, that material manages to still achieve thermal resistances up to 182.5 C as well as good tensile strength and impact resistance performance. Such material types’ lightness and mechanical durability are ideal for additively manufactured UAV frames and structural parts, particularly in today’s increasingly weight-conscious markets.

For customers deviating from that trend, other printable carbon materials are specialised for greater durability and resilience. One example of these is printed with a tensile strength of 85.25 MPa, and exhibits continued performance under extreme temperatures and stresses, enabling it to serve in applications with harsh environments and intense mechanical forces, such as brackets, functional prototypes and enclosures that must perform reliably under severe conditions to achieve key certification standards.

And as hybrid and electric powertrains must increasingly be built for high voltage and battery material hazards (such as thermal runaways and fires), printable flame-retardant composites are coming that combine specialised resins and carbon or glass reinforcements to achieve the UL 94 standard (for safety of flammability of plastic materials for parts in devices and appliances testing) V-0 rating. For those unfamiliar, V-0 is the most stringent of flame-retardancy classifications under that regulation – and said material achieves it while still being mechanically robust and halogen-free.

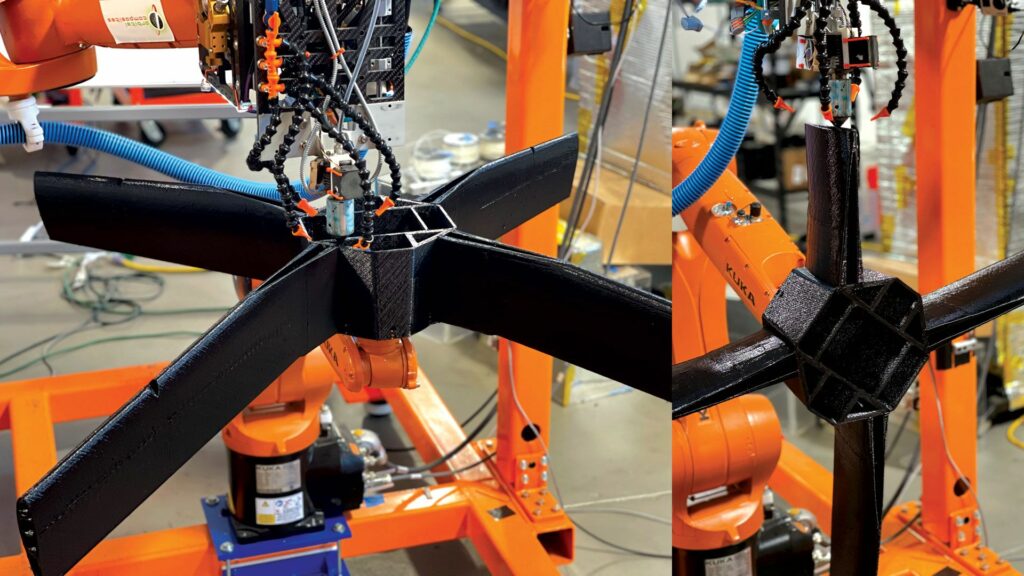

(Image courtesy of Orbital Composites)

Other UL 94-compliant materials are also formulated to meet the FAA’s FAR 25.853 standard for flammability in aircraft interior environments; these exhibit good dielectric properties and thus work well in electrical housings and enclosures, not to mention other components where both fire resistance and electrical insulation are required. Additional printed composite varieties that specialise further in dielectric properties and high-voltage applications are available, with some withstanding peak voltages of up to 2.5 kV/mm and exhibiting dielectric constants of approximately 4 at 1 kHz, enabling reliable insulative properties in new aerospace and automotive powertrains (as well as related or closely proximate subsystems).

On top of this are some particularly new advancements in technology for printing continuous fibres, unlike the conventional approach of using chopped fibres amidst the printed matrix additives to impart carbon, glass or other reinforcers’ properties into the finished composite. This means, at long last, that composite parts can be printed with the same levels of material integrity as traditionally laid-up, impregnated or cured composite products, but also with more complex geometries and in less labour-intensive production processes.

Such technology has moved from experimental trials to large batch production in recent years, with key advantages of the proprietary manufacturing techniques including its agnosticism to the exact nature of the continuous material being embedded in the resin – not to mention agnosticism to the resin.

As a result of the former, parts produced using these technologies can include strands of copper woven into the material, with appropriate isolations and terminations for creating functional circuit boards integral to composite panels, tubes or other parts. Naturally, extensive weight and packing volume can be saved by adopting such dual- or multi-purpose material: a wing generating lift on its outside might function as a flight controller, battery management system or ECU on its inside. Additionally, the weaving of copper or other highly conductive materials into a composite part enables the creation of ground planes for RF systems and lightning strike protection, or if nothing else, power transfer between different off-the-shelf subsystems without the weight or potential hazards of a cable.

The latter agnosticism or modularity has also encouraged experimentations with alternatives to conventional resins. Most notably, those behind such technologies have found soaring demand for thermoplastics over the more widely used thermosets such as epoxy resins. While thermoplastics had fallen out of favour across much of the aerospace field owing to regulations and norms favouring the greater mechanical strengths and chemical stabilities of thermosets, the former’s significantly lower weight (while still retaining decent durability and impact resistance) is making it popular in light of the primacy of weight reduction in today’s uncrewed applications – particularly in frontline applications where certification may need to take a back step in favour of other priorities.

Moreover, the production tooling of such systems is miniaturised and cartridge-ised to the point that it can fit on the end effector of autonomous robotic arms. Such arms are available in mobile-deployable industrial solutions ranging from small cells for printing small, finished, composite drone airframes (complete with subsystem circuit boards or motherboards for mounting chips and avionics) in 10–12 hr stints per individual unit, up to 40 ft containerised solutions of arms and effectors capable of printing very large components weighing hundreds of kilograms.

By connecting multiple autonomous arms in a wired network with facilitated tracking of each other’s positions and manoeuvres, continuous or additive materials can be extruded onto different angles of a product simultaneously, thereby adding material to a composite part akin to how multi-axis CNC machines subtract materials from billet. The arms can also ‘hand-off’ pieces to each other as needed, to achieve different angles for addition or setting of material, or coating or painting of near-finished parts, much like a mill-turn machine pre-programmed to lathe-cut a metal part in multiple angles or zones – thus setting the stage for composite printing to join CNC machines in mainstream manufacturing.

While conventional composite parts are challenging to monitor for QC as they are cured, SLS and other additive printing techniques can be both monitored and calibrated closely for each material. Parameters such as laser power, scan speed and layer thickness can be optimised to maintain repeatability and dimensional accuracy, and these parameters can be assessed as each part takes shape in the additive chamber.

Additives for sintering or extrusion can also be managed and controlled tightly, with additive composite companies working to store, condition and handle them in controlled environments to ensure consistent print quality, while post-build powder reuse rates are monitored to prevent degradation of mechanical properties.

And as with other materials, printed composites from high-end suppliers will undergo visual inspection and dimensional checks using traditional metrology tools as well as 3D scanning systems. These inspections verify that part geometries have been printed within tolerances, with no surface defects or irregularities, especially for parts with tight fits or functional interfaces.

Waste not

Going forwards, the most glaring missed opportunity (and hence scope for future improvement) in composite technologies lies in material wastage, given both the aforementioned minimum order requirements and the lack of second or third lives given to the raw materials.

A few interesting innovations are, however, visible across the additively printed composite realm. In particular, given the general recyclability of thermoplastics, their growing use in composites – both conventionally produced and additively printed – presents a variety of pipelines for more sustainable composite products in future.

One supplier’s practices, for example, include grinding up cancelled or respecified print orders of thermoplastic-based composites and using the resulting powders to print moulds in future prototyping work.

Another company’s approach takes ground-up thermoplastic composite and combines it with discontinuous fibre to form a composite laminate layer atop a continuous-fibre composite, creating an end product reinforced with better material properties and providing a wide range of possible features too cumbersome to achieve with conventional continuous-fibre material alone. These include strengthening of key zones, edge sealing, placements of stiffening ribs, thickness variations and use of bosses for spreading fastener-induced strain.

Alternatively, another supplier will take powders originally intended for composite laser sintering, but which have reached end-of-life owing to particle degradation or contamination, and reprocess them into a new raw material for injection moulding, rather than discarding them.

As much as sustainability is an end unto itself, it is also a financial imperative: composites remain an expensive option compared with injection moulded plastics and similar materials, not to mention some mass-produced, aviation- and maritime-grade aluminium parts among the larger UAVs and USVs featured in recent years. Thus, while weight saving is king for now, it would not be surprising to see those who master recovery and full remanufacturing of composite materials at end-of-life – thereby skipping the costs of bulk orders of prepreg or raw materials – one day taking future leadership in the composite space.

(Image courtesy of Scabro Innovations)

Acknowledgements

The author would like to thank Brian Fallow of Decavo LLC, Martijn Asser of Scabro Innovations, Danu Chokitapanich of Cobra International, Franco Cevolini of CRP Group, Mike Graham of Real Carbon, Inc., and Cole Nielsen and Amolak Badesha of Orbital Composites for their help in researching this article.

Some examples of composites manufacturers and suppliers

AUSTRALIA

| Composite Components | +61 861 913 046 | www.compositecomponents.com.au |

| Ultimate Composites | +61 429 010 008 | www.ultimatecomposites.com.au |

CANDA

| Harwood Custom Composites | +1 250 656 0392 | www.harwoodcomposites.com |

FRANCE

| Pyromeral | +33 3 44 723 477 | www.pyromeral.com |

| Rexiaa Group | +33 4 73 897100 | www.rexiaa-group.com |

GERMANY

| Schuetz | +49 2626 77 0 | www.schuetz-composites.net |

| UB Composites | +49 7144 8143 0 | www.ubc-gmbh.com |

ITALY

| Bercella | +39 0525 53680 | www.bercella.it |

| CRP Group | +39 0598 21135 | www.crp-group.com |

SWEDEN

| Diab International | +46 430 163 00 | www.diabgroup.com |

| Oxeon AB | +46 33 340 18 00 | www.textreme.com |

SWITZERLAND

| Connova | +41 56 619 10 90 | www.connova.com |

| North Thin Ply Technology | +41 21 811 08 88 | www.ntpt.tech |

| Swiss Fibertec | +41 55 451 11 44 | www.swiss-fibertec.com |

THAILAND

| Cobra International | +66 384 54219 | www.cobrainter.com |

THE NETHERLANDS

| Scabro Innovations BV | +31 714 017 246 | www.scabroinnovations.com |

UK

| 3DDC | +44 1234 391894 | www.3ddc.eu |

| Formtech Composites | +44 1235 436070 | www.formtech-composites.co.uk |

| IPECO Composites | +44 1702 545 1181 | www.ipeco.com |

| Piran Advanced Composites | +44 1841 521 011 | www.pirancomposites.com |

| Polar Technology | +44 1865 592240 | www.polartechnology.co.uk |

| Rockwood Composites | +44 1626 240026 | www.rockwoodcomposites.com |

| SHD Composites | +44 1529 307629 | www.shdcomposites.com |

UAE

| Polar Manufacturing | +971 504 105 078 | www.grouppolar.com |

USA

| ACP Composites | +1 925 443 5900 | www.acpsales.com |

| Applied Composites Engineering | +1 317 243 4225 | www.appliedcomposites.com |

| Carbon by Design | +1 760 643 1300 | www.carbonbydesign.com |

| CRP USA | +1 704 660 0258 | www.crp-usa.net |

| Decavo | +1 541 716 0100 | www.decavo.com |

| Orbital Composites | – | www.orbitalcomposites.com |

| Oxeon Inc | +1 925 872 5659 | www.textreme.com |

| Protech Composites | +1 360 573 7800 | www.protechcomposites.com |

| Real Carbon | +1 360 210 5212 | www.realcarbon.com |

| Rock West Composites | +1 801 566 3402 | www.rockwestcomposites.com |

| Swift Engineering | +1 949 492 6608 | www.swiftengineering.com |

UPCOMING EVENTS