AUVSI Xponential part two

Unconventional autonomy

The Xponential 2025 convention in Houston showcased some of the latest designs and innovations upon which our collective autonomous future depends. Peter Donaldson was there to take stock

In the second part of our coverage of Xponential 2025 in Houston, we focus on new subsystems and components for a broad range of applications including electronic warfare, infrared sensing, navigation, communication, flight management, manufacturing, plus reliability and range/endurance extension.

Aeronix Technologies Group (ATG) discussed its new Digital High Probability of Intercept (DHPOI) technology, a breakthrough solution designed to detect and identify signals intended to have a low probability of intercept amid dense electromagnetic noise. DHPOI enables precise detection and classification of signals of interest while filtering out ‘interferers’ – signals transmitted deliberately to mask signals of interest – enhancing the electronic warfare capabilities of uncrewed vehicle systems. Applications span airborne, ground and maritime platforms, offering a critical edge in signal discrimination.

“We’re demonstrating the ability to distinguish between closely located signals and ignore unwanted ones,” said Derek Lyons of Aeronix. The technology, an offshoot of electromagnetic spectrum operations, is part of the US Navy’s Multi-Intelligence Sensor Development program for electronic intelligence. “We’ve now increased our ability – through the digitisation of the technology – to see more signal and more noise and to distinguish between the two,” he added.

DHPOI features a wide instantaneous bandwidth of 16 GHz, enabling detection of signals from a frequency range of 2–18 GHz. It relies upon radio frequency (RF) system-on-chip technology, which allows for the digitisation of the RF spectrum for better signal-to-noise resolution. Eventually, it will include patented algorithms that use machine learning to isolate and classify signals of interest in noisy environments. Furthermore, time–frequency transform processing reveals hidden signals by analysing frequency variations over time, and its ultra-low latency (<500 ns) enables the real-time threat response critical in electronic warfare.

Ainstein showcased its latest US-D1 Pro radar altimeter, designed for UAV applications in harsh environments. The recently announced altimeter is designed to offer reliable above-ground-level measurements from 0.5 to 120 m – covering a much-needed mid-range altitude for the UAV market – through simple integration.

“Our radar sensors don’t require calibration; once plugged in, they’re ready to go,” said Ainstein’s Nash Sloan, highlighting the advantages over barometric sensors. The US-D1 Pro is designed to DO-160/178/254 aviation standards, and it boasts an IP69K ruggedised rating, making it suitable for agricultural, surveying and delivery drones.

Pedro Lopez of Ainstein noted the challenges of frequency constraints: “We’re limited to 24 GHz for airborne applications, but we optimise antenna design and software to maximise performance.” The system emits frequency-modulated continuous wave signals in the millimetre-waveband, making it ideal technology for detection in rough environmental scenarios (such as when dust, spray or fog are present). Furthermore, the RadAlt tech offers reliable readings over land and water.

With collision avoidance emerging as a critical UAV requirement, Ainstein aims to adapt its downward-facing altimetry tech for forward-looking applications – pending regulatory shifts. Deliveries of the US-D1 Pro are scheduled to start in August 2025.

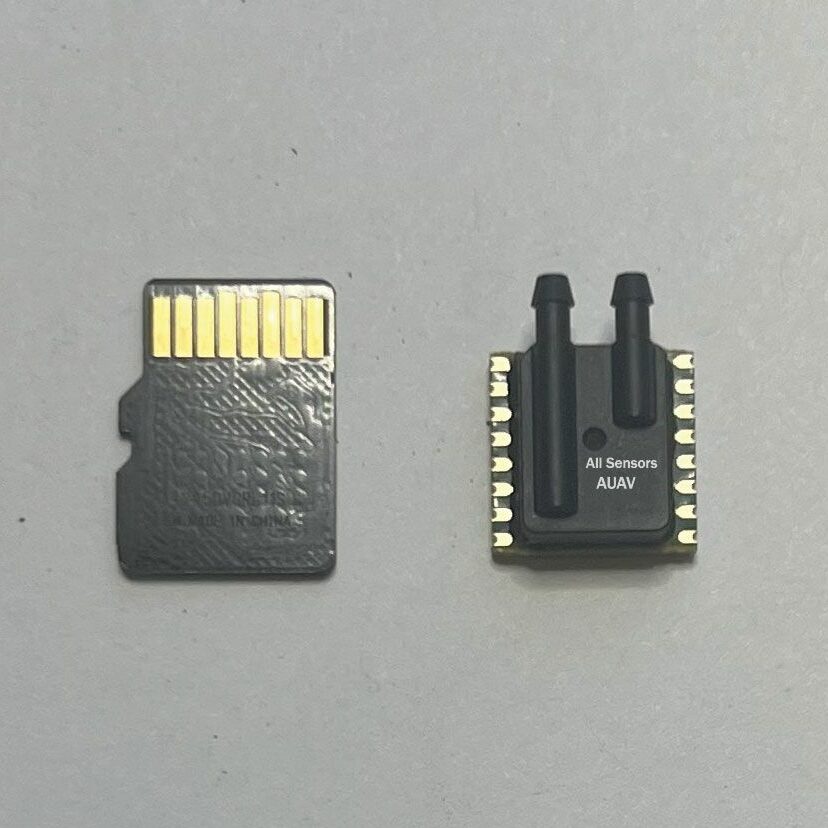

All Sensors (an Amphenol company) has introduced a new dual airspeed and altitude sensor tailored for UAVs. The MEMS-based device combines ultra-low-pressure sensing technology – originally developed for medical ventilators – with high-resolution calibration to address critical stall detection and landing challenges in uncrewed systems.

“Our sensor eliminates the need for recalibration and isn’t sensitive to vibration or position, which is a game-changer for low-speed accuracy,” said Jim McNeil of All Sensors. The compact unit (approximately 15 mm x 13 mm) integrates two cross-coupled sensing dies to cancel common-mode errors, achieving stable zero-offset performance. Priced at under US $25 per unit in high volume, it is aimed at delivery drones, loitering munitions and light aircraft.

The sensor is based on piezoresistive MEMS technology in the form of a Wheatstone bridge circuit, delivering precise differential pressure measurements between two pressure ports with 24-bit ASIC compensation. Initially designed for sub-1 PSI ranges, it now supports up to 400 in of water pressure, expanding into higher-speed UAV and aerospace systems.

With a medical-grade heritage, the sensor delivers high reliability and performance in demanding environments. It is currently being integrated into a wide range of applications across industries such as military, aerospace, delivery logistics and environmental monitoring. A development kit is available through authorised distributors such as DigiKey and Mouser, helping engineers accelerate design and integration.

Applied Navigation introduced its Quattro Flight Management System (FMS), a next-generation autopilot designed for modularity and redundancy in uncrewed aircraft. The system features a compact system-on-module with triple-redundant inertial measurement units with dissimilar dynamic ranges and from different manufacturers, thereby ensuring failover capability during highly dynamic manoeuvres.

“Our modular approach lets users integrate only what they need, whether it’s a radio-equipped variant or a minimal I/O carrier board,” said Patrick Bettale of Applied Navigation. The Quattro FMS includes Ethernet, USB-C and dual redundant power (7–30 V), while remote nodes handle air data and compass heading sensing, as well as local servo control, eliminating pneumatic connections for easier wing integration.

The Quattro natively supports STANAG 4586 for seamless ground control via Vigilant Spirit software, originally developed by the Air Force Research Lab. Deep configuration of flight controllers, sensors and mission parameters is provided by an independent engineering tool, allowing the operator to focus solely on achieving mission objectives without unnecessary clutter.

Developed from scratch over four years, the Quattro FMS prioritises safety and mission success through rigorous preflight checks and contingencies built into the flight control software stack, with applications in military UAVs such as the AeroVironment Jump-20, the Platform Aerospace Vanilla and the PteroDynamics XP-4.

The Quattro measures 103 mm long, 62 mm wide and 24.5 mm high, weighs 122 g and consumes 4 W.

Attollo Engineering showed its Griffin 5L series mid-wave infrared (MWIR) camera core, featuring a unique broadband sensitivity range from 900 nm to 5 μm – unlike conventional MWIR systems that are limited to 3–5 μm. This expanded range supports broadband imaging together with day and night laser see-spot capabilities. It also enables novel applications, such as seeing through windows in certain conditions, a capability typically restricted to short-wave infrared (SWIR) sensors, said Michael Costolo of Attollo.

Costolo added that the camera features tiny 5-micron-pitch detectors, putting more pixels on target with a short focal length lens, reducing overall sensor size – a breakthrough Attollo pioneered. He admitted that there are trade-offs to choosing many small pixels over fewer large ones, gaining resolution at the expense of sensitivity and range. “What people like about the sensor is that it sees lasers very well, which is very important for many defence applications.”

The Griffin also integrates a Stirling-cycle cryocooler, critical to the sensitivity of the company’s Type II superlattice detector material. Attollo’s vertical integration – designing its own readout integrated circuits and detectors – ensures tight control over performance trade-offs.

The Griffin camera is poised to fill gaps in multi-spectral sensing for uncrewed systems, potentially bridging MWIR and SWIR functionalities.

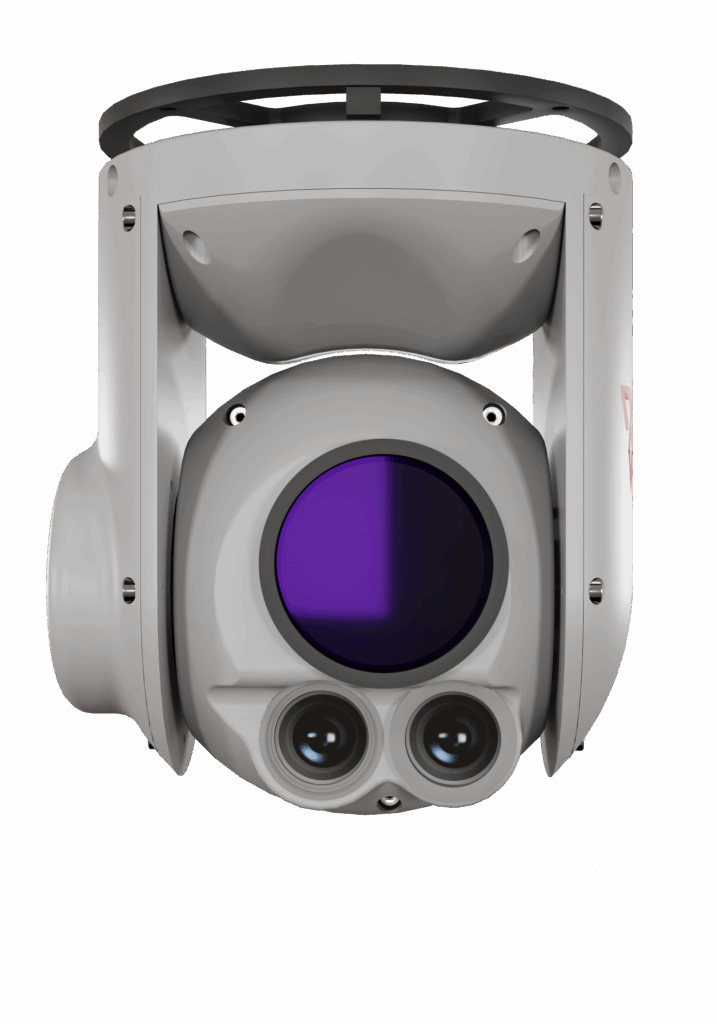

Blitz Technology has unveiled its Spectrum 300 and Spectrum 500 gimbal-mounted EO/IR systems, which the Turkish company designed to bridge the gap between low-cost Chinese sensor systems and premium Western alternatives. The compact Spectrum 300 and 500 systems weigh 330 and 500 g, respectively, and combine 4K EO and HD/SD IR sensors (ITAR-free) for ISR missions on Group 1–3 UAVs.

“We’re positioning these as cost-competitive solutions without compromising on quality,” said Kadir Dogan of Blitz Technology. The systems feature 3D-printed polymer housings paired with machined aluminium internals to minimise weight while maintaining structural precision.

Stabilised to better than 0.1 mrad, both belly mounted turrets have unlimited rotation in azimuth and from -135° to +45° in elevation at speeds of up to 40/°s and angular accelerations of up to 40°/s2. Software provides roll correction.

Both models feature similar HD day cameras based on Sony’s 4056 x 3040 element STARVIS2 colour CMOS sensor, differing in zoom level and field of view (FoV). The Spectrum 300’s camera offers 40x zoom and three selectable FoVs: 60° and 3° optical and 1.5° digital (e-zoom), while the Spectrum 500’s corresponding figures are 50x, 60°, 2.4° and 1.2°, respectively.

The 300 and 500 systems also have similar longwave infrared microbolometer cameras from Teledyne FLIR, each based on a vanadium oxide focal plane array of 640 x 512 and 1280 x 1024 elements, respectively. The 300 offers 6x zoom and FoVs of 18° and 3°; the 500’s corresponding figures are 10x, 34° and 3.4°, respectively.

Both are manufactured in-house, with production scaling to 200–300 units/month.

Centum unveiled Cellair, a lightweight airborne cellular system designed to restore critical communications during disasters. Weighing 830 g, the 5G-capable unit creates private networks for first responders when terrestrial infrastructure fails, enabling voice, data and video sharing via standard smartphones.

“It’s a game changer for emergencies – deployable in minutes with any drone that can support it,” said Centum’s Héctor Estévez. The system acts as a standalone secure cellular base station, creating immediate coverage and allowing standard phones to connect without relying on existing infrastructure. Unlike bulky alternatives, Cellair integrates antennas and processing in a single ruggedised box, requiring only power and an airborne platform to create the network – although it can also be deployed on ground vehicles, boats or carried in a backpack.

Developed from Centum’s proven Lifeseeker search-and-rescue technology, Cellair enables tactical and emergency teams to maintain mission-critical communications in zones affected by disasters such as wildfires, floods or earthquakes.

Its modular and SWaP-optimised architecture supports deployment on a wide range of platforms. The system has been selected by NASA for its Extravehicular Activity and Human Surface Mobility Program Communications Architecture.

Contromax unveiled the ServoMax12 miniature actuator, engineered for small UAVs requiring high reliability in mission-critical applications. Unlike hobby-grade servos, ServoMax12 draws from military and safety critical design principles, supporting platforms like fixed-wing UAVs.

Beyond ServoMax12, Contromax offers a range of ServoMax actuators with torque ratings from 7.5 to 500 kgf·cm, all compliant with Mil-Std-810, 461, 704 and RTCA/DO-160. Several redundant models including the 100D, 150D and 400D are in development to meet evolving safety and redundancy standards.

“Our PMS [permanent magnet synchronous] motor control technology delivers seamless, linear motion unlike traditional six-step commutation used in BLDC [brushless DC] motors, which often struggle with precision,” said Thomas Chae of Contromax. “Six-step commutation can have difficulty suppressing ‘jitter’ – the uncontrolled oscillation of output position – when actuators are coupled to external aircraft structures such as control vanes or surfaces. This is typically caused by uncontrolled inertia and external disturbances. That’s why we engineered a more robust, high-precision motor architecture, providing our customers with better performance while still maintaining competitive pricing.”

Contromax’s actuator product line is aligned with FAA/EASA standards and best practices, forming a key part of its broader push into the tactical UAS market, where demand is rising for durable and optimised actuator solutions.

Honeywell launched its HGuide o480, which is a compact OEM navigation system designed to maintain precision in GNSS-denied or contested environments. The single-card solution combines a sub-tactical-grade IMU (sub-1°/h gyro bias) with a Septentrio Mosaic anti-jam/anti-spoof GNSS receiver, which features advanced interference monitoring and mitigation (AIM+) technology, and multi-constellation support.

Key to its resilience is Honeywell’s ensemble navigation architecture, which fuses inertial data with aiding alternative inputs such as Iridium signals or Lidar odometry. The new navigation system is planned to be a key building block for resilient positioning, navigation and timing (PNT) by pairing it with Honeywell alternative navigation technology in the future. “It’s about maximising performance in minimal space – supporting vision, radar, magnetic and future RF [radio-frequency]-based alternative navigation sensors,” said Chris Matthews of Honeywell.

The 71 x 45 mm module is targeting UAVs, autonomous ground vehicles and marine systems. It integrates Ethernet/PTP synchronisation and has support for ROS drivers. The system’s been designed to have high vibration tolerance (500°/s gyro range) and suits dynamic platforms – but not spin-stabilised ones, Matthews pointed out – while its software developer kit supports custom integration.

With multiple global conflicts and civilian incidents highlighting GNSS vulnerabilities, the HGuide o480 aims to address growing demand for robust PNT. With its modularity and planned support for emerging alternative navigation technologies, the system is intended to offer a future-ready core navigation functionality for autonomous systems operating in degraded environments. The HGuide o480 is now available for integration.

HP Additive Manufacturing Solutions has demonstrated how its Multi Jet Fusion (MJF) 3D printing technology is transforming UAV production, enabling lightweight, high-strength designs with rapid iteration capabilities. HP displayed more than 15 drone models built using MJF, highlighting its adoption across aerial and underwater uncrewed systems.

“Our technology allows drone manufacturers to topology-optimise parts, reducing weight by up to 25% while maintaining strength,” said Brian Ingold of HP AM Solutions. The process uses nylon powders (PA12, PA11) and elastomers (TPU) to create complex geometries in a single print, eliminating assembly steps. MJF’s 12 hour print cycles can produce more than 20 drones per batch, with customisable agents fine-tuning durability and surface finish.

Notable applications include NECO’s RDR (a one-piece reconnaissance drone) and Blueflite’s delivery UAVs, which use MJF printing for modular battery casings and body panels. The technology also supports field-deployable production, aligning with military demand for on-site manufacturing.

MJF offers a scalable alternative to injection moulding, particularly for manufacturers who need to evolve their designs rapidly. MJF is a multi-agent, multi-pass printing process with voxel-by-voxel (3D pixel equivalent) control, which uses heat lamps to melt and fuse material in layers and specific areas. Each new layer comes down while the one below is still molten, with the extra time spent above the melting point promoting more polymer entanglement within and between layers to make parts stronger.

Packet Digital, in collaboration with Black Sky Aerospace and the Naval Research Lab, has achieved a breakthrough in laser power beaming, transmitting 600–800 W over 8 km in a March demonstration at White Sands Missile Range. Funded by DARPA, the project integrated Packet Digital’s maximum power point tracking (MPPT) technology, which optimises conversion of energy from sunlight, or lasers in this case, into energy stored in batteries at 98% efficiency despite dynamic conditions.

The system uses lasers to deliver power to solar-cell-equipped receivers, enabling applications like long-endurance UAS charging or orbital energy distribution. Packet Digital’s MPPT algorithms adjust the electrical load up to 1000 times per second using a high-efficiency DC–DC converter to manage voltage and thermal loads, explained Packet Digital’s Terri Zimmerman.

The company also showcased its UAS battery technology with its high-energy- and high-power-density packs. The company’s custom lithium cobalt oxide cells are engineered to balance endurance and thrust, enabling longer flight times and rapid mission execution, aided by custom designed battery management systems (BMSs) – manufactured in the Fargo facility, which includes an SMT line, laser and ultrasonic welders, and BMS and battery cell test equipment

“We tailor chemistries to optimise either energy density for endurance or power density for thrust, depending on the mission,” Zimmerman said. Packet Digital’s BMS enhances safety with real-time monitoring, predictive health analytics and fleet management integration, Zimmerman added.

RPX Technologies has launched the EmbIR UAV-640 LWIR, a 9.1 g long-wave infrared (LWIR) camera designed for seamless UAV integration. The company says that the sensor is the lightest thermal camera on the market and the only standalone Blue UAS-certified thermal imaging solution, meeting stringent DoD supply chain requirements. The sensor supports both reconnaissance and autonomous navigation in degraded environments and is priced at less than $2000.

“We eliminated the mechanical shutter to prevent IMU interference and frame blanking, which is critical for GPS-denied navigation,” said Matthew Dock of RPX. In addition to shutterless operation, the camera boasts low thermal inertia of 8 ms, feeding into low latency that enables real-time motion tracking.

Based on an uncooled 640 x 480 element vanadium oxide microbolometer sensor chip with pixel pitch of 12 microns, the camera has a standard frame rate of 30 Hz, with 9 Hz as an option. In terms of power consumption, it draws 800 mW at 3.8–5.5 V.

The camera offers analogue (NTSC) or digital (USB) outputs, supporting plug-and-play compatibility with FPV drones and flight controllers. Its 9.1 g weight is complemented by its dimensions, measuring 19.3 mm high x 19.9 mm wide x 20.5 mm deep. Manufactured in Oklahoma (US), the UAV-640 LWIR is now in production.

Sony Electronics Inc. showed its new AS-DT1 compact Lidar depth sensor. The device delivers 576-point 3D depth mapping, measuring the distance to each point in a 24 x 24 point array within a 20/40 m range, targeting autonomous UAVs, UGVs and other mobile robots.

Sony Electronics’ Koki Iwazaki emphasised that the AS-DT1’s size and performance make it unique in the world: “Nobody else has such a product. We are the first!”

Measuring 2.9 cm wide x 2.9 cm high x 3.1 cm deep, the AS-DT1 weighs just 50 g. Covering ranges up to 40 m indoors and 20 m outdoors, the sensor is accurate to ±5 mm in both cases, achieving a distance resolution of 0.25 mm. Unlike single-point rangefinders, it provides real-time distance data for each point, enabling precise obstacle avoidance and navigation. The AS-D1 also supports AI-driven object recognition and terrain mapping.

The laser emits light at the wavelength of 940 nm, and the receiver is based on single-photon avalanche diode (SPAD) technology; the sensor measures distance using the direct time of flight method. SPADs achieve high sensitivity through avalanche multiplication, in which a single incident photon excites large numbers of electrons through an effect akin to an avalanche.

“The most highly praised aspect is the stability and precision of each individual depth point, resulting in a high-quality point cloud,” Iwazaki emphasised.

Maxon presented its dual-redundant-winding motor design, offering fail-safe operation. The Swiss manufacturer’s innovation features two independent motor windings on a single stator, enabling seamless transition to a backup system if the primary winding fails without adding bulk or weight.

“This solution is ideal for space or aircraft applications where reliability is paramount,” explained Jason Vaccaro of Maxon. The design maintains the same form factor as standard motors but interleaves two sets of windings, each operable via separate power supplies and controllers. While peak power is slightly reduced, compared with a brushless DC (BLDC) motor of the same size, the redundancy ensures continuous operation in high-risk scenarios.

Maxon’s UAV motors, which produce up to about 10 kg of thrust, exploit the company’s BLDC technology for efficiency and reliability. All components, the motor, electronic speed controller and propeller are optimally matched to achieve optimum efficiency in the overall propulsion system, Vaccaro said. Additionally, the entire UAV propulsion portfolio has been through DO-160 G environmental testing.

The redundant winding option (currently custom-built) targets aviation and space applications requiring fault tolerance. Maxon’s UAV propulsion systems are developed and manufactured in Switzerland. The company continues to expand its portfolio, offering tailored UAV propulsion solutions that are either customer-specific modifications or fully custom-built systems.

Near Earth Autonomy is scaling its autonomy systems across aircraft ranging from lightweight drones to helicopters such as the Leonardo AW139 and Sikorsky UH-60 Black Hawk. The company brings significant aerial autonomy experience with 10,000+ autonomous flights across 140+ airframes.

Near Earth’s aircraft- and sensor-agnostic systems can integrate options including Lidar, stereo cameras and radar to suit specific application needs. They can also provide obstacle avoidance, GPS-denied navigation, take-off and landing on ships and operation with hand-deployed precision landing beacons.

The company’s systems are built on its Captain architecture, which provides a deterministic, safety-critical framework. Unlike probabilistic AI systems, Captain employs verifiable algorithms that enable certification and ensure predictable performance. Near Earth also adopts a Modular Open Systems Approach, enabling rapid upgrades, flexible mission capabilities and fleet-wide scalability across both legacy and modern VTOL platforms.

In partnership with Honeywell and Leonardo, Near Earth recently completed the first autonomous flight of a Leonardo AW139 under the US Marine Corps’ Aerial Logistics Connector program.

“By directly commanding the AW139’s flight modes through our autonomy system, we’ve demonstrated that scalable, autonomous logistics on existing platforms is no longer just a concept, it’s a reality today,” said Dr Sanjiv Singh of Near Earth Autonomy.

Other milestones include selection for the USMC’s Tactical Resupply Unmanned Aircraft System Demonstration program, where Near Earth’s 1 kg Firefly system equips TRV-150 drones for frontline resupply, and the US Army’s Catalyst program to retrofit UH-60L Black Hawks with Near Earth’s Rotorcraft Uncrewed Capability (RUC-60) kits. Autonomous flight with a safety pilot is targeted for 2026, with fully uncrewed flight expected in 2027.

Xsens discussed two recently launched IMU families – Sirius and Avior – designed for demanding uncrewed systems and offering yaw accuracy better than 1° RMS. Sirius is a ruggedised IMU built for harsh airborne, marine and land environments, while Avior serves as an OEM version intended for integration into larger systems. Both feature industrial grade MEMS gyroscopes, dual processors and an analogue signal pipeline for reliable, high-accuracy data in dynamic conditions.

“Our sensors guarantee drift-free performance in the long term, even in low or high dynamic scenarios,” said Martina Ravizza of Xsens. “We calibrate each sensor individually to guarantee that it performs well.”

Certified to Mil-Std-202, CE, FCC and RoHS standards, Sirius is not subject to US ITAR rules. Rated to IP68, it measures 56.5 mm x 40.9 mm x 24.75 mm, weighs 78.5 g and supports RS232, RS422 and CAN interfaces.

The compact and lightweight Avior series targets embedded applications. With an IP51 rating, it depends on system enclosures for environmental protection, weighing 35.2 g and measuring 36.8 mm x 40 mm x 15.7 mm. Avior supports a wide variety of interfaces, including UART, CAN, SPI, I2C, RS232 and RS422.

Xsens also offers extensive support, including software development kits and magnetic field mapping tools to counter interference.

UPCOMING EVENTS