Commercial UAV Expo 2025

(All images courtesy of the author unless otherwise stated)

Hitting the jackpot

As a leading international trade show and conference, the Commercial UAV Expo is the place to explore the current realities and future frontiers of the drone industry. Peter Donaldson went to learn more

Held at the Caesar’s Forum exhibition centre in Las Vegas on September 2–4, the Commercial UAV Expo presented a cornucopia of enabling technologies for uncrewed vehicle development and operation. These included powertrain components from energy storage to motors and propellers, navigation, georeferencing and communication systems, anti-jam antennas, air traffic awareness, management, and UAV tracking devices, autopilots and servos, composite materials and sensors.

ANELLO Photonics revealed more about the performance of its Silicon Photonic Optical Gyro (SiPhOG) technology designed to enable precise navigation for UAVs in GPS-denied or -contested environments. The system exploits silicon photonics to shrink fibre-optic gyro technology into a compact, mass-producible form factor.

The core of the system is a photonic integrated circuit that contains all the optical components, including splitters, couplers, phase modulators, filters and detectors and is based on using a simple laser diode. This ‘fibre gyro on a chip’ measures rotation with accuracy of 50 nanoradians, providing a stable inertial reference unaffected by temperature, vibration or electromagnetic interference. When integrated into a GNSS-INS unit, the system can maintain navigational accuracy within 0.1% over 100 km without GPS signals, according to ANELLO’s Mario Paniccia.

A key capability is spoofing detection. The system compares its precise inertial position with GPS data every 10 ms. “If GPS for example gives you a radically different answer that you know to be physically impossible, you know you’re being spoofed,” Paniccia explained. This allows the unit to identify and reject deceptive signals, switching entirely to inertial navigation using the ANELLO system when necessary.

The technology is currently deployed in land, air and maritime applications. The three-axis product – called X3 – available for UAVs accounts for wind and banking during flight, while the maritime INS takes currents into account. Future development aims to further shrink the system using silicon nitride resonators, increasing performance while reducing size and power consumption. This roadmap points toward eventual integration into small, battery-operated handheld navigators for personnel operating in GPS-denied areas.

ANELLO’s manufacturing process is designed for high volume, with fabrication partners and automated calibration ensuring scalability.

CubePilot showcased its latest hardware, highlighting its focus on system redundancy and integration flexibility for professional UAV applications. The centrepiece of the display is the CubeOrange Plus autopilot. The unit features triple redundancy on its IMUs and magnetometers, along with double redundant barometers. Also on show were the latest GPS modules, the Here4 and Here4 Blue, with the key difference being the integrated Remote ID module in the Blue variant. This provides a solution for operators employing two GPS units for moving baseline applications because only one module is required to broadcast Remote ID.

The CubeRed autopilot was also on display. Having been tested by initial users, an updated version is slated for re-release within the next few months following user feedback and design changes, which will also bring a price reduction. Users who have purchased a CubeRed will receive the revised version at no charge.

The company also showed several carrier boards to suit different integration needs. Among them were the standard breakout board, the compact Cube Mini carrier board and the all-in-one Kore multi-rotor carrier board. The Kore board is designed for streamlined builds, routing power and PWM signals to the arms and providing onboard power for payloads.

A smaller development module, the CubeNode, was also highlighted. This chip-down module allows manufacturers to design custom peripherals. “If you have a special airspeed sensor for example that you want to use, that no one makes a unit for a drone for, you can more easily design your own, allowing easier development and faster time to market,” explained Chris Sweeting of authorised CubePilot distributor NW Blue. The module runs CubePilot’s Ardupilot AP_Periph software and communicates with the main autopilot via CAN bus or Ethernet.

Calian GNSS (formerly Tallysman) highlighted its portfolio of precision antennas designed for the UAV market, with a focus on resilience and miniaturisation. The product line includes several form factors. Helical antennas, such as the HC977SXF (32 g) and HC979XF (42 g), offer a compact, lightweight solution for multi-copters where reduced size, weight and power consumption are paramount. For fixed-wing or larger drones requiring a low-profile antenna, Calian offers ceramic patch antennas, like the TW3990EXF, although these are heavier and need a ground plane.

A key emerging focus is anti-jam capability. The company’s two-element controlled reception pattern antenna (CRPA), the CR7712EXF, operates in the GPS L1 band, weighs approximately 135 g and consumes 60 mA of current at 5 V. It dynamically steers a planar null toward a jammer in real time, mitigating interference. “It detects a jammer, and it adapts the reception pattern to form a null towards it,” explained Calian’s Joseph Botros.

For applications not requiring extreme accuracy but needing reliable GNSS, this lightweight CRPA provides a critical layer of protection against intentional interference. The company also offers a larger, more capable four-element CRPA, the CR8894SXF+, for platforms that can accommodate its half-kilogram weight.

Later this year, Calian plans to introduce its new Accutenna 4 technology. Based on a composite patch with four feeds, it will provide full-band coverage and phase centre stability in a lighter package than traditional ceramic patches, with an integrated ground plane to simplify integration.

The company, an Ottawa-based division of the Calian group, manufactures all its antennas in North America.

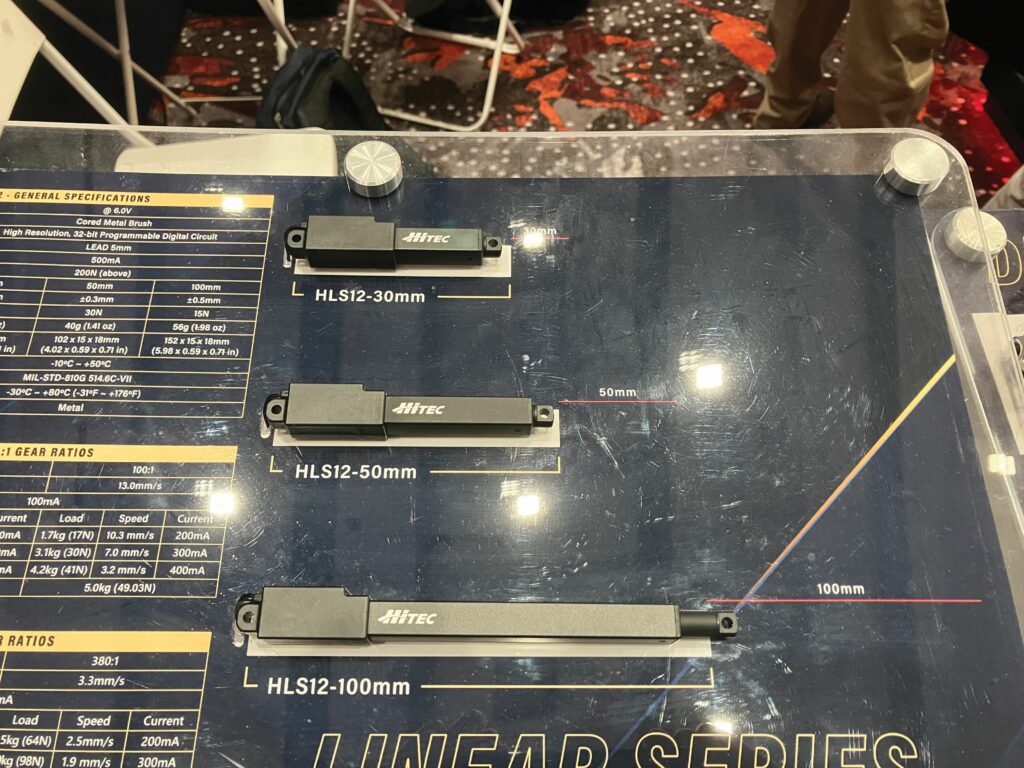

Hitec showed a new line of CAN linear servos that embodies a shift towards more integrated and data-rich actuation for professional UAV applications. The servos are offered in the same stroke lengths and gear ratios as their PWM counterparts but communicate via CAN or DroneCAN protocols.

This allows for real-time feedback of critical data including voltage, temperature and position directly over the CAN bus. The servos were demonstrated operating with a Cube autopilot, with only signal wires required for control. To support the architecture, Hitec is also releasing dedicated breakout boards. These boards manage power distribution and signal routing, a necessary component of CAN protocol, which dictates against long wires from peripheral devices.

The company is also expanding its high-voltage offerings with 28 V versions of its 941 and 951 servos, which feature a wide operating range of 8–32 V. The MDB941 is designed for high speed in large helicopter applications, while the 951 balances the need for speed and torque. “The MDB961 is one of our top-selling servos,” stated Shawn Spiker of Hitec. “The integrators and the manufacturer are looking for something they don’t have to worry about in terms of reliability – it could be in a million-dollar drone, easily.”

aircraft wing flaps, as their worm drives can hold position without using power

For extreme environments, Hitec showcased its rugged SG series and an upcoming underwater servo, the SU-33BL, rated for operation at 1000 m depth. A redundant version of the 33 mm sized servo, the SR-33BL, is also in development.

The new linear servos use a worm gear design, making them ideal for applications like flaps or release mechanisms where they must hold position without consuming power. They are currently available in strokes up to 100 mm.

LightWare is addressing the growing need for standardised peripheral connectivity in professional UAVs with its recently launched DroneCAN adapter. The adapter enables true plug-and-play compatibility between a wide range of LightWare LiDAR sensors and popular flight controllers that support the DroneCAN protocol.

The unit allows operators to seamlessly swap sensors in the field without additional coding or integration effort. “DroneCAN gives the end user the ability to really do a plug-and-play swap of any peripheral device,” explained Andre Schoemann of LightWare. The adapter maintains a daisy-chain capability with two ports, ensuring users do not run out of connectivity points.

Weighing just 3 g, the adapter aligns with LightWare’s focus on minimising size, weight and power (SWaP) impact. Engineering the adapter required no compromise to the standard DroneCAN messaging protocol, ensuring broad compatibility. The company utilises the same chipset found in its existing sensors, which also ensures compliance with NDAA sourcing requirements.

The strong uptake of the adapter signals a maturing market moving toward standardised architectures for easier system integration. LightWare plans to eventually integrate the DroneCAN interface directly into its LiDAR sensors, further simplifying deployment. The adapter represents a key step in reducing integration barriers and enhancing operational flexibility.

Protech Composites showed samples of its US-manufactured carbon fibre parts made with vacuum infusion technology. The company uses dry woven carbon fibre sourced from North Carolina and California, infusing it with epoxy to create flat sheets and moulded parts with guaranteed zero porosity.

The process allows for control over thickness, finish and complex geometries. Components range from machined drone chassis and vertical struts to moulded body covers, says Protech’s Dylan Parmeter. The company uses a three-axis CNC router for 2.5-dimensional machining, creating features that cannot be economically moulded, such as sharp angles or precise hole patterns. “There’s not a lot of industry in our area performing vacuum infusion with guaranteed zero porosity,” Parmeter noted.

Protech Composites also produces hybrid composites using fibreglass or coloured variations. Recent investments include a 24 in x 24 in platen hot press, which will enable more complex moulded parts using prepreg materials under heat and pressure. The company can also machine Kevlar, but working with this material is difficult because it frays excessively, so carbon fibre remains their speciality.

Protech focuses on flat and moulded components that require high cosmetic finishes and structural integrity, recommending partners for tubular components such as multi-copter arms. All design work is based on customer-supplied DXF or DWG files, with everything manufactured in-house to ensure quality and compliance with ‘made-in-USA’ requirements.

Riegl presented its range of UAV-based LiDAR sensors, emphasising turnkey solutions developed with UAV manufacturer partners. The company’s focus is on providing holistic, integrated payloads that combine its precise time-of-flight LiDAR with uncrewed platforms that comply with US National Defense Authorization Act (NDAA) requirements stipulating the use of components originating in the US or allied countries.

The LiDAR lineup includes the powerful VUX-16023, suitable for both UAV and crewed helicopter use, shown integrated on a Skyfront Perimeter 8+ hybrid octocopter. The workhorse VUX-12023 was displayed on a Harris Aerial H6E electric hexacopter, offering over 90 minutes of flight time when converted to the gas-hybrid configuration. The entry-level miniVUX-3UAV, paired with Riegl’s IMU/GNSS solution (RiLOC-E), was fitted to an Inspired Flight IF800 quadcopter, providing a lightweight alternative competing with DJI Matrice-sized aircraft.

A key strategy is partnering with reliable drone affiliates to simplify the customer experience. “We’re taking the opportunity to work with vetted drone providers that offer NDAA compliant systems that are very reliable and thoroughly tested,” explained Riegl USA’s My-Linh Truong.

The LiDAR systems are designed for operational independence, drawing power directly from the drone and using a dedicated GNSS antenna. Data recording can be triggered automatically upon power-up or via a PWM signal for precise control during flight line acquisition. This level of integration is intended to provide a seamless workflow for both existing Riegl clients transitioning to drones and new operators entering the LiDAR market.

Silvus Technologies presented its SL5200, a new 2 W mobile ad-hoc network (MANET) radio designed for the small uncrewed air systems (sUAS) market. The radio achieves 4 W effective performance via transmit eigen beamforming, and represents a significant reduction in size and weight, weighing just 52 g compared with the company’s previous smallest radio of 122 g.

The SL5200 maintains the advanced capabilities of Silvus’ larger StreamCaster 4200 and 4400 MANET radios. Including high bandwidth throughput up to 100 Mbps, and scalability of 550+ nodes. In addition, the SL5200 provides available access to the company’s proprietary ‘Spectrum Dominance 2.0’ EW resiliency features, an expansive software suite designed to maintain network performance in contested electromagnetic environments. While some capabilities are ITAR-controlled, the suite features low probability of intercept/low probability of detection (LPI/LPD), anti-jamming and advanced threat protection, including dynamic power control, interference avoidance and cancellation, as well as waveform resilience.

The new form factor is aimed at expanding Silvus’ reach into the smallest drone platforms without sacrificing link robustness. “We’re really going after the sUAS market and making sure that customers can communicate effectively in the toughest environments,” said Silvus’ Paul Blackham.

The SL5200 is designed for simple integration, requiring only power, Ethernet and antennas for operation. The radio runs the company’s MN-MIMO waveform, which provides the foundation for its advanced features. When asked about the potential for artificial intelligence, Blackham noted that AI in this market is “in its infancy,” but that the company is investigating more fluid, processed AI approaches for future development.

The SL5200 is currently available in both low-cost and regular variants with different feature sets.

Sunhillo displayed its latest UAS traffic management hardware and software, its development drawing on 34 years of air traffic control experience. The company’s focus is on integrating multiple sensors to provide a cohesive airspace picture for uncrewed operations.

A key new product is SureSky, a multi-band receiver prototype capable of receiving ADS-B (1090 MHz), UAT (978 MHz), and Remote ID signals. The IP67-rated, weatherproof unit is designed for permanent outdoor installation or portable deployment, outputting standard (Eurocontrol) ASTERIX CAT 21 and CAT 33 data formats. “With this simple unit… it brings in all three different receivers,” explained Doug Walczak of Sunhillo. The system is intended for cities or emergency management teams to monitor both crewed and uncrewed aircraft simultaneously.

The company also showcased its established Margate 2 ADS-B receiver, which is in use across all US military branches and can provide up to 200 miles of range. These data, along with input from radar systems, are fused and displayed through Sunhillo’s surveillance monitoring system software. The data fusion capability combines overlapping tracks from different sensors into a single target, reducing screen clutter.

For cybersecurity, the SureSentry data diode provides a hardware-enforced one-way path for sharing sensitive radar or government data with external parties without risking a reverse intrusion. This is critical for secure distribution of airspace information.

SureSky is undergoing certification and is expected to be available next year. It represents a move toward more deployable, integrated receivers that simplify the process of gathering comprehensive airspace data for UAS operators and airspace managers, supporting the growing need for scalable and secure situational awareness.

Taisync has announced the production release of the new fully NDAA-compliant version of the RC7, a 7 in ground control radio – such compliance being a critical requirement for US government and defence-related procurement.

Achieving compliance required a significant supply chain and manufacturing overhaul. Every component, from active chips down to passive resistors and capacitors, was scrutinised to ensure no Chinese-branded parts were used. All printed circuit board fabrication, assembly and final product integration now take place in Taiwan. “We examined the bill of materials and made sure we don’t use Chinese-branded components,” explained Yan Li of Taisync. “The whole controller is assembled in Taiwan; the finished product, everything is done in Taiwan.”

This process extends beyond the RC7 to the company’s airborne radio modules, which underwent the same rigorous supply chain vetting and manufacturing relocation. The effort to establish NDAA-compliant production lines has been a primary focus for Taisync over the past 18–24 months. The company has produced the RC7 on a large scale in Japan, and in small batches in the US.

Concurrently, Taisync is establishing a dual-source manufacturing capability, with new production facilities coming online in Taiwan and South Korea. This strategy is designed to provide resilience and ensure a continuous supply of compliant components for the professional UAV market. The development underscores a broader industry shift, whereby engineering resources are increasingly allocated to navigating complex regulatory and sourcing requirements alongside traditional product innovation.

Trimble Applanix presented its APX RTX and PX1-RTX OEM boards, highlighting their role in enabling high-precision direct georeferencing for drones. The APX RTX provides real-time, subscription-based centimetre accuracy via L-band satellite correction for mapping using photogrammetry and/or Lidar. The PX1-RTX is targeted at applications requiring precise navigation, such as drone delivery and automated control.

A key focus is on the shift from traditional airborne mapping using ground-based control points to airborne direct georeferencing, which uses onboard GNSS and inertial measurements to precisely position imaging sensor data. This method eliminates the need for ground surveys, allowing drones to georeference Lidar and imagery directly during flight. “We remove the control from the ground and put it up in the air in your vehicle, and it’s actually more accurate,” explained Applanix’s Dr Mohamed Mostafa. This approach avoids distortions inherent in 2D map projections, leveraging fully 3D geodetic systems for greater accuracy. In addition, when APX RTX is used, base stations are no longer needed.

OEM integrators for these systems, including Riegl, YellowScan and PhaseOne, successfully interface the systems with various imaging and Lidar sensors. Trimble Applanix also offers post-processing toolbox software to calibrate sensors, correct trajectory data, and integrate photogrammetry and Lidar outputs. The technology is positioned as a critical enabler for efficient, accurate aerial data collection without dependency on ground control.

uAvionix is scaling its FlightLine network, which is a federated network of ground-based ADS-B sensors designed to provide low-altitude cooperative traffic surveillance for uncrewed aircraft systems. The network, originally developed for the UAS industry and now adopted by the FAA, supports both crewed aviation safety initiatives and drone operations.

FlightLine data are accessible through uAvionix’s ‘FlightLine Portal’ or a standardised CAT 021 API, integrated with UAS service suppliers such as AirspaceLink, Aloft, Motorola CAPE or Votix. This infrastructure is positioned as critical for enabling scalable beyond visual line of sight operations by providing reliable low-latency traffic awareness.

The system recently achieved certification for monitoring airspace around non-federally owned air traffic control towers under the new Airborne Position Reference Tools programme. It has additionally been approved under the FAA’s Surface Awareness Initiative to enhance airport safety and efficiency by providing air traffic controllers with improved, real-time views of aircraft and vehicle movements on the airfield runway and taxiway surfaces.

For UAV operators, the service allows entities like police, fire departments or delivery services to receive ADS-B air traffic data only for a specific region of interest to them. The company is preparing for upcoming Part 146 regulations, which will formalise requirements for Automated Data Service Providers. “Once the Part 146 structure comes out and goes from draft to final, we intend to seek certification and approval right away,” said Thomas Jiménez, of uAvionix. “We are confident that we are well positioned with the experience gained in our FAA ADS-B deployments and hope to be ‘good to go’ from day one.”

Alongside the network, uAvionix showcased Trakr, a new self-contained device that can be attached to any UAV using Velcro. Operating on 915 MHz, it transmits positional data to TrakrStation receivers, enabling fleet monitoring without integration into the drone’s telemetry system. This provides a simple solution for organisations to track assets on a common interface while keeping their data private inside the operator’s network.

The company also manufactures a suite of onboard avionics for UAVs. All hardware is designed and assembled in the US.

Upgrade Energy showed its Amprius Gold Series battery line, designed to significantly extend UAV flight times. The commercially available batteries are reported to provide between 20% and 40% more flight duration compared with that of standard lithium-ion or lithium-polymer packs.

The company, based in El Segundo, California, partners with cell manufacturers like Amprius to utilise high-performance silicon-anode cells. Upgrade Energy’s core expertise lies in packaging these cells with minimal supporting architecture to maximise energy density. A key differentiator is the use of copper welding instead of nickel for interconnects, improving electrical efficiency. “We put a lot of work into developing methods of manufacturing batteries using copper welding technology,” stated Upgrade Energy’s Matt Barnard.

The packs are constructed using specialised tapes, thermally stable adhesives and composite materials to manage mechanical and thermal constraints. The external polymer casing provides basic protection, but the company offers a trade-off: ultra-lightweight packs for maximum performance or more robust versions with added structure for impact resistance.

The batteries are categorised by application: the ‘Red’ series is optimised for flights of 10–30 minutes, ‘Gold’ for 20–60+ minutes and ‘Green’ for 40+ minutes. This simplifies selection for integrators of fixed-wing and multi-rotor platforms. Manufacturing and testing are conducted in-house, with a focus on thermal management and validation to ensure safety and performance. The products are available for direct order and ship globally.

Vertiq, a manufacturer of integrated motor and electronic speed controller (ESC) modules, highlighted new customisation options aimed at improving UAV performance and simplifying assembly. The company’s motor modules include an embedded rotary encoder for position sensing, which increases motor efficiency, power and responsiveness, and allows for advanced telemetry and enhanced safety protocols.

A key development is the introduction of downward-eject wiring connections. This design allows wiring to pass through a multi-copter’s hollow arm rather than externally, improving ingress protection. The option is available for all motor sizes except the 23-series, their smallest models. “It helps with dust protection and waterproofing, and makes vehicles look quite sleek,” explained Vertiq’s David Schwartz.

The company also offers protective covers to safeguard the motor from solid debris. The rotor cover mounts on top of the motor, shielding it while functioning as a fan that draws air through the motor to enhance cooling. The coil cover and stator cover protect the underside of the motor and the ESC, respectively. As with the wire harness, Vertiq provides standard configurations and offers custom options.

Additionally, Vertiq has an integrated LED position lighting option directly connected to the motor module. This eliminates the need for a separate power wire running along the arm, reducing weight and simplifying assembly.

Vertiq produces motors to a base module level, then customises the final wiring, motor cover and LED configuration based on customer requirements, thereby reducing lead times and costs compared with fully custom motor development. The largest motor in the lineup is the 81-17, which provides 10+ kg of continuous thrust with a 26 in propeller. A larger model capable of 17 kg of continuous thrust is in development.

UPCOMING EVENTS