Fibre-based pressure sensors

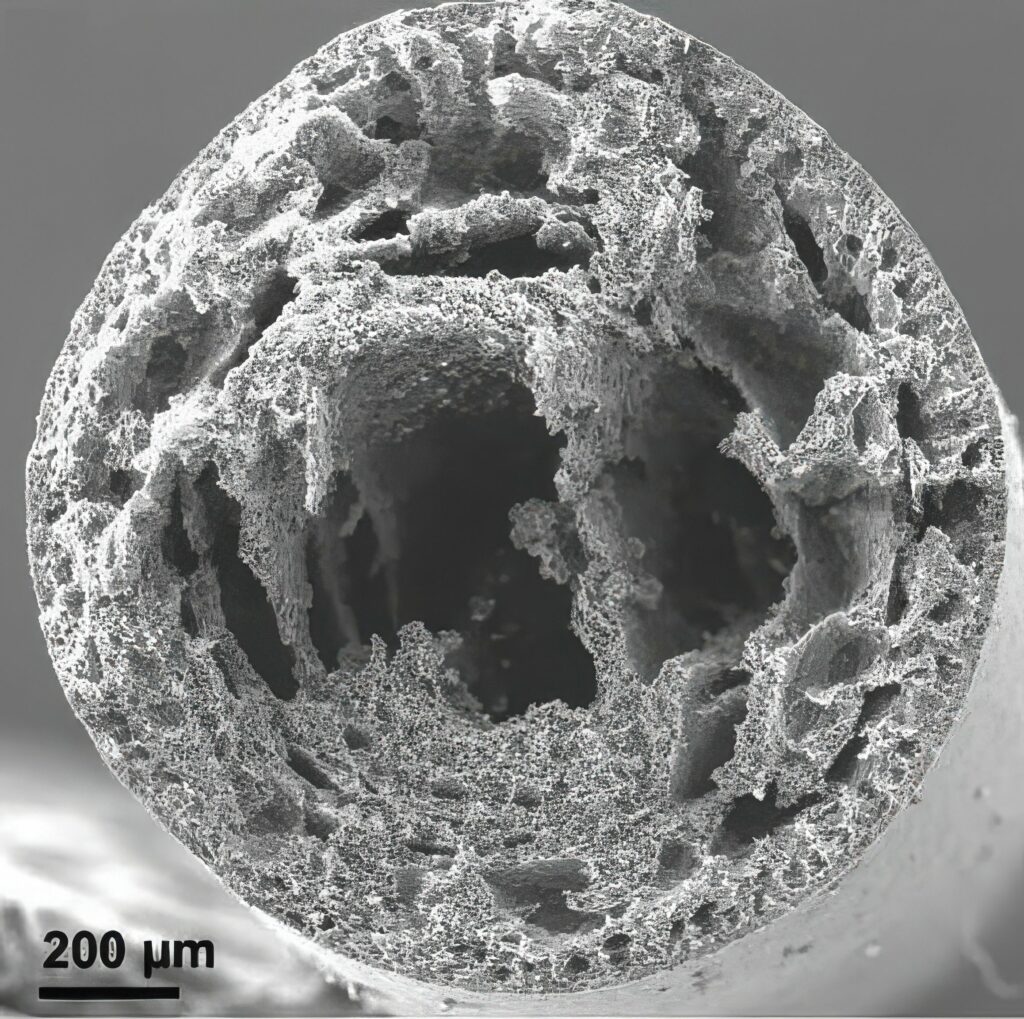

(Image courtesy of Shinshu University)

Researchers in Japan have developed a new type of pressure sensor using fibres, writes Nick Flaherty.

Measuring pressure from the distortion of hydrogels or films using decreasing resistance when the fibre is compressed, requires sensitive measurement equipment that can be bulky. Instead, a team at Shinshu University in Japan developed a fibre where the resistance increases with pressure, thereby allowing more sensitivity in the measurements.

The multi-walled conductive core of the fibre, made from graphene nanoplatelets, modulates resistivity under pressure.

The new fibre is prepared via a coaxial wet-spinning process, producing a smooth outer shell of thermoplastic polyurethane (TPU) and titanium dioxide (TiO2) and a core containing 2D graphene nanoplatelets (GNPs). The core layer contains the TPU in a concentration half that of the shell layer but is loaded with a significant amount of high-surface-area GNPs. The van der Waals interactions and self-stacking behaviour of the flat GNPs creates the multi-wall structure that is critical to the function of the fibre.

When a portion of the fibre is compressed, the internal multi-wall structure bends and develops microcracks. These microcracks disrupt the conductive pathways of the axially aligned GNPs, causing a sharp increase in the fibre’s electrical resistance. This mechanism allows the fibre to produce a highly responsive signal, even when only a small section is compressed. To put this into perspective, a sensor using the fibre is sensitive enough to detect a light fingertip touch with a minimum pressure of only 0.1 N.

As the applied pressure increases, the electrical resistance response of the fibre also increases. At 1 N, the resistance reaches ≈2.5 times its initial value and the resistance signal continues to increase with rising pressure. Notably, at 5–6 N, there is a sudden resistance jump – from a 40-fold increase at 5 N to a 110-fold increase at 6 N. Beyond this point, the rate of resistance changes to decrease slightly under higher pressures.

The high aspect ratio of the fibres makes them suitable for applications that require fine-grained feedback in tight spaces, including monitoring in UAVs and UGVs with grippers. For instance, in soft robotics, these fibres could be integrated into the fingertips of robotic grippers.

“Most available tactile sensors used on robotic hands are rigid, which poses the risk of causing discomfort or even injury during contact with humans. In contrast, fibre-shaped flexible pressure sensors offer both comfort and compliance, reducing the risk of harm,” said researcher Dr Chunhong Zhu, associate professor at Shinshu.

The fibre can be used to distinguish between different types of tactile events. The researchers showed that by using wavelet transforms on data from a three-fibre array, they could accurately differentiate between various forms of presses and slides. “This capability is particularly valuable for the tactile sensing of frictional states, enabling robotic systems to distinguish between static and dynamic friction, potentially allowing robotic manipulation to become as nuanced and dexterous as that of humans,” said Dr Zhu.

“Our work could be seen as the beginning of a new subfield – introducing a distinct fibre-based pressure sensor architecture and offering a working prototype with solid performance,” he added.

UPCOMING EVENTS